EGR (Exhaust Gas Recirculation) mixer for marine diesel engine

A marine diesel engine and mixer technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve problems affecting the reliability of the engine, and achieve the effect of simple structure and avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Supercharged intercooling technology means that the fresh air is supercharged by the turbocharger, cooled by the air cooler, and then flows to the cylinder combustion chamber through the intake manifold and intake valve. The effective intercooling technology can reduce the temperature of the supercharged air below 50°C, which helps to reduce exhaust emissions and improve fuel economy.

[0029] Fresh air after supercharging and intercooling refers to fresh air after supercharging and intercooling.

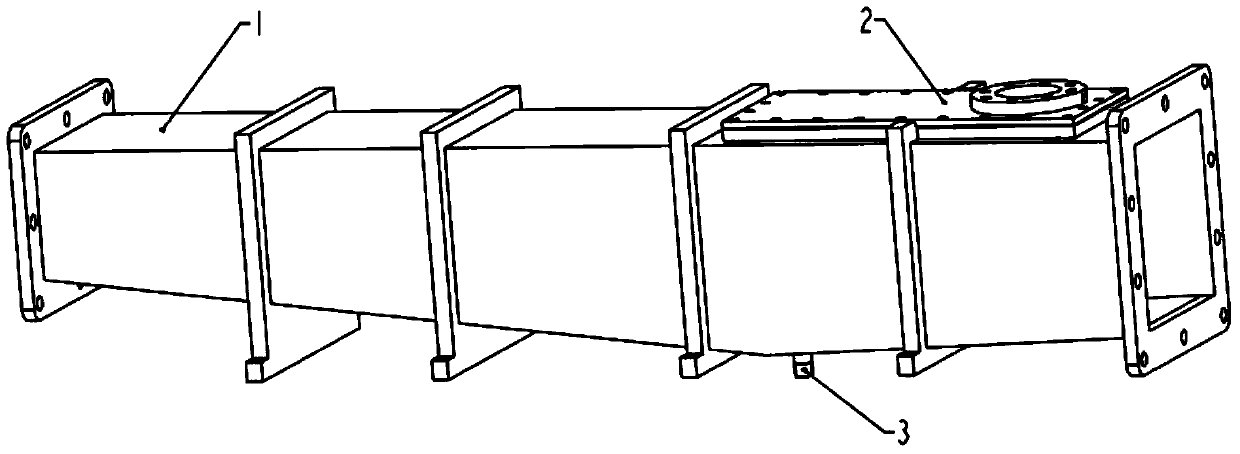

[0030] Such as figure 1 , figure 2 As shown, an EGR mixer for a marine diesel engine according to an embodiment of the present invention includes a mixer housing 1 , an EGR gas introduction device 2 and a release hole 3 .

[0031] The release hole 3 is located at the lowest position on the bottom surface of the mixer housing 1, and its axial direction is perpendicular to the flow direction of the fresh air after the supercharging and intercooling.

[0032] The bottom surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com