Sound absorption board

A technology of sound-absorbing panels and square panels, applied in the directions of roads, tracks, buildings, etc., can solve the problems of inconvenient use, poor sound-absorbing effect of sound-absorbing panels, and easy cracking, etc., so as to reduce the contact surface, maintain the sound-absorbing effect, and increase the absorption. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

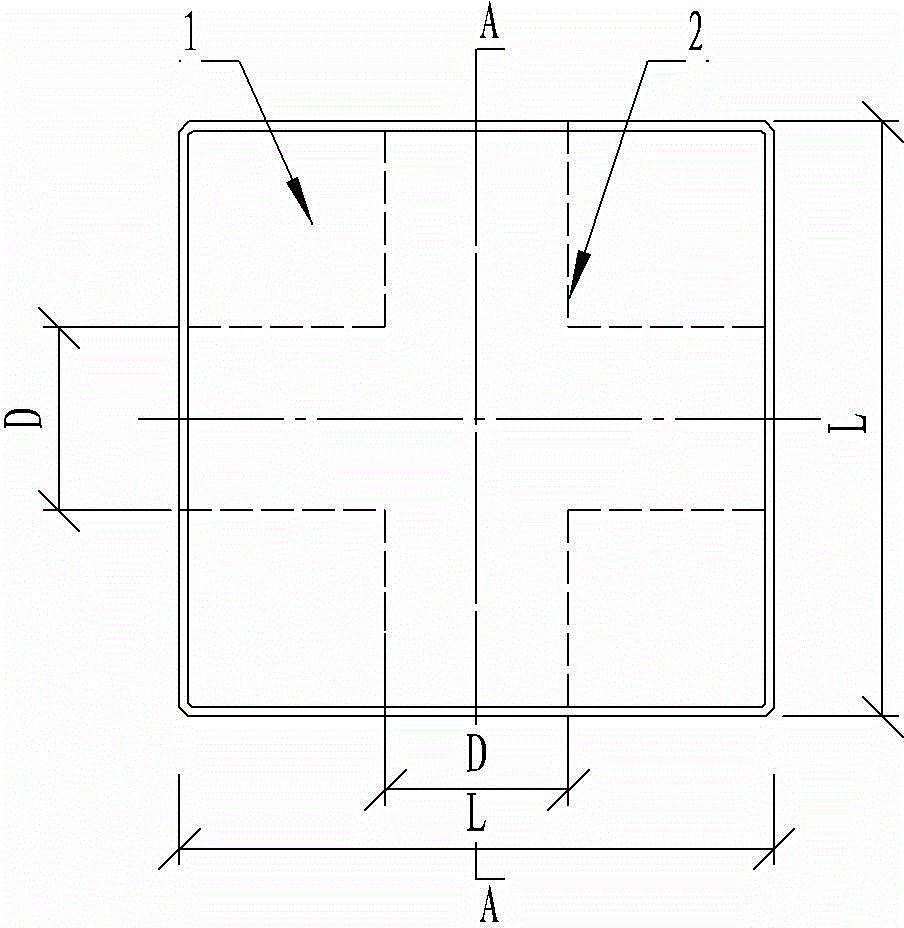

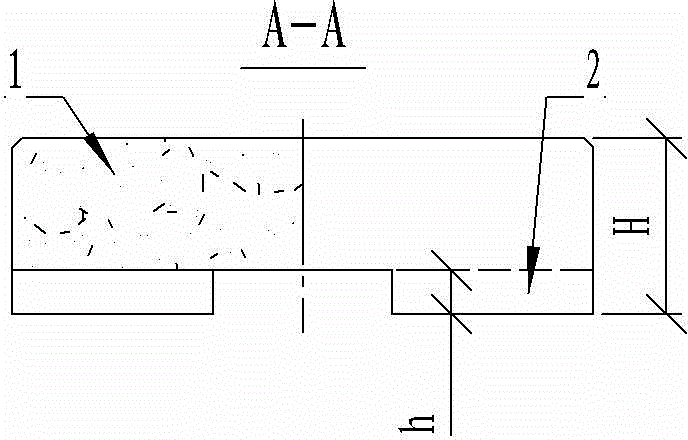

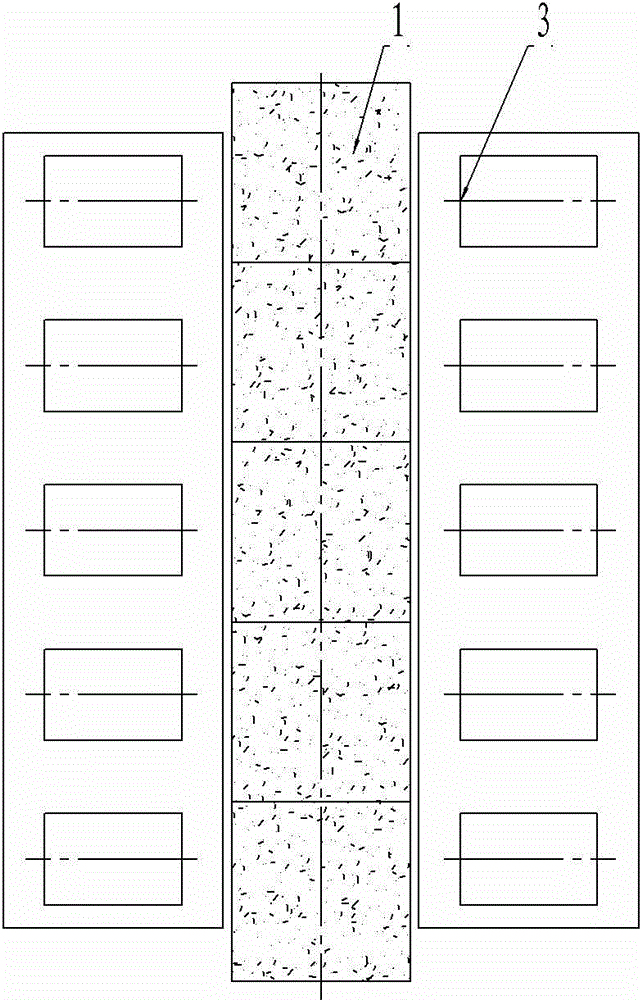

[0016] Such as Figure 1 to Figure 4 This sound-absorbing panel shown, it comprises square plate 1, and this square plate 1 is cube, and its upper surface is as figure 1 The square plate 1 is viewed from above and its four sides are all L in length. There is a cross groove 2 at the bottom of the square plate 1. The cross groove 2 extends to the four longitudinal end faces of the square plate 1. The width D of the cross groove 2 and the height h The size can be adjusted according to the sleeper height of the specific ballast bed structure. Such as image 3 The sound-absorbing board is placed on the bridge deck between the two rail bearing platforms or on the bridge deck 3 in the middle of the trapezoidal sleeper track bed to fill the gap on the bridge deck and can absorb sound on the track bed all day long. The four corners at the bottom and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com