Connecting rod for a weaving loom and weaving loom comprising this connecting rod

A technology for connecting rods and looms, which is applied in the processing of connecting rods, textile materials, weaving, etc., can solve the problems of not being large enough, the operator is obstructed, and not conforming to ergonomics, and achieve the effect of simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

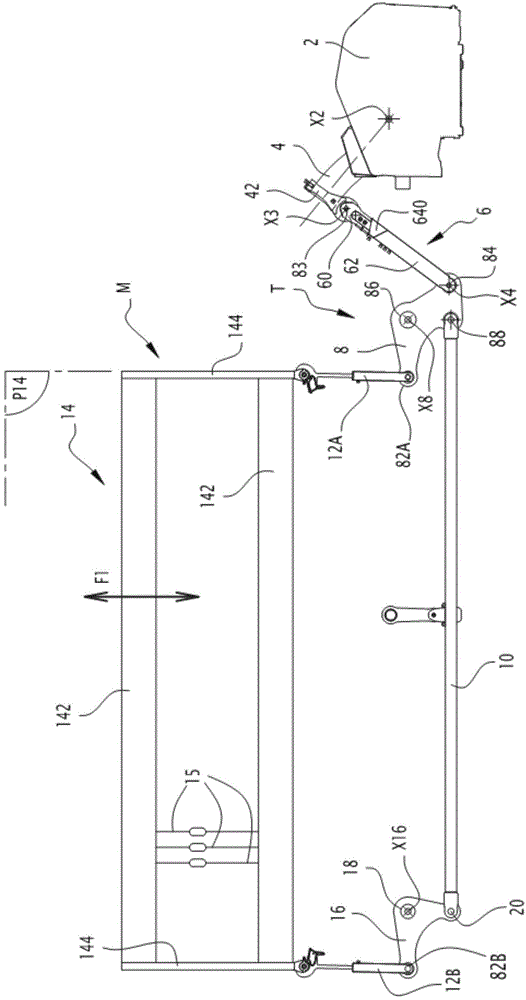

[0035] figure 1 Shown is a weaving machine M according to the invention comprising a plurality of heddle frames 14, only one of which is shown and marked with the reference numeral 14 . The heald frame 14 is composed of two uprights 144 and two crosspieces 142 . The plane where the heald frame 14 is located is defined as a plane P14 , that is, the plane P14 is formed by two straight lines extending along the uprights 144 and the crosspieces 142 . Plane P14 is also figure 1 The plane on which it is located. The heald frame 14 is provided with tens or even hundreds of heddles for guiding warp yarns, figure 1 Only three of them are shown in , marked with reference numeral 15. Although for ease of description, figure 1 Only one heald frame 14 is shown in the figure, but in actual use, in order to form a shed in the warp yarn, at least two heald frames must be used. The direction of layer moves heald frame 14, and motion direction is along figure 1 In the direction indicated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com