Cane juice neutralization reaction enhancing method based on multi-stage hydrodynamic cavitation

A technology for hydrodynamic cavitation and cane juice, which is applied in the purification, application, and sucrose production using alkaline earth compounds, can solve the problems of reduced sugar recovery rate, incomplete reaction, large residual amount, etc., and achieves high equipment utilization rate and good effect. , the effect of strengthening the application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: The method for strengthening the neutralization reaction of sugarcane juice by multi-stage hydraulic cavitation is used in the traditional sulfiting sugarcane juice clarification process. The traditional sulfite sugar clarification process includes: pre-ashing, primary heating, sulfur fumigation Neutralization, degassing, secondary heating and settling processes, etc. (such as Figure 14As shown), a multi-stage hydrodynamic cavitation enhanced cane juice neutralization reaction process is added between the gas diffusion and the secondary heating process. The multi-stage hydrodynamic cavitation enhanced cane juice neutralization reaction process is to The cane juice from the neutralizer and the diffuser is pumped into the multi-stage hydraulic cavitation to strengthen the cane juice neutralization reaction device to continue the neutralization reaction of the cane juice, so that the neutralization reaction can be carried out more thoroughly, and the neutralizat...

Embodiment 2

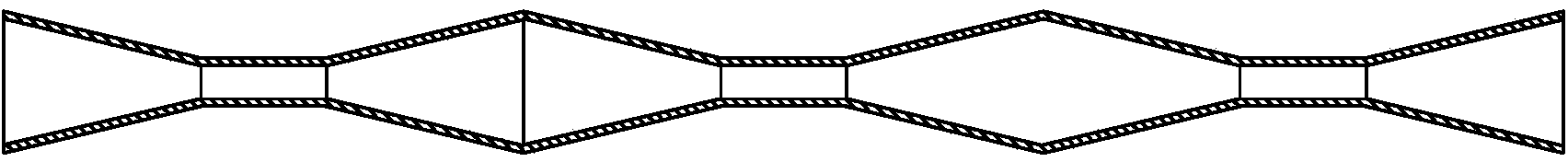

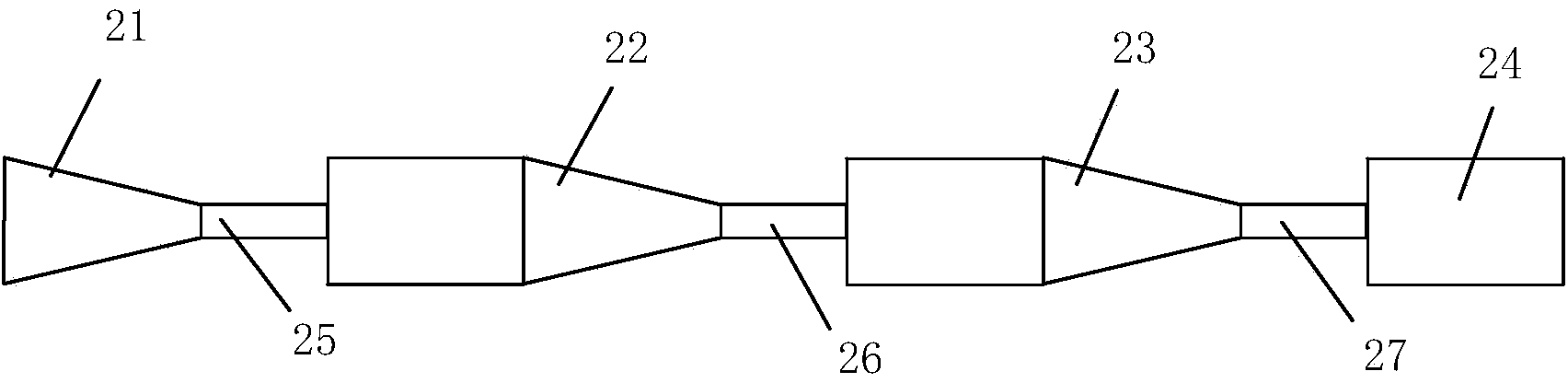

[0036] Embodiment 2: The method for the neutralization reaction of sugarcane juice strengthened by multi-stage hydraulic cavitation, its basic procedure is the same as that of Example 1, the difference is that the multi-stage hydraulic cavitation enhanced neutralization reaction device of sugarcane juice adopted is the same as that of Example 1 The specific structure of the sugarcane juice is not the same, the multi-stage hydraulic cavitation used in this embodiment to strengthen the sugarcane juice neutralization reaction device (see Figure 3-Figure 4 ) is composed of trumpet-shaped tube Ⅰ21 (ie, inlet tube), connecting tube Ⅰ25, cylindrical horn combined sleeve Ⅰ22 (ie, intermediate tube), connecting tube Ⅱ26, cylindrical horn combined sleeve Ⅱ23 (ie, intermediate tube), which are connected in sequence. Connecting pipe III 27, cylindrical pipe I 24 (i.e. outlet pipe), the cylindrical horn combined sleeve I and cylindrical horn combined sleeve II have a structure in which the...

Embodiment 3

[0037] Embodiment 3: The method for the neutralization reaction of sugarcane juice enhanced by multi-stage hydraulic cavitation, its basic procedure is the same as that of Example 1, the difference is that the multi-stage hydraulic cavitation enhanced neutralization reaction device of sugarcane juice adopted is the same as that of Example 1 The specific structure of the sugarcane juice is not the same, the multi-stage hydraulic cavitation used in this embodiment to strengthen the sugarcane juice neutralization reaction device (see Figure 5 ) is connected successively by the cylindrical tube Ⅰ31 (i.e. the inlet pipe), the connecting pipe Ⅰ35, the horn-shaped combined tube 32 (ie the intermediate tube), the connecting tube Ⅱ36, the cylindrical horn combined sleeve 33 (ie the intermediate tube), the connection Tube III37, cylindrical tube II34 (namely the outlet tube), the trumpet-shaped composite tube I is composed of two trumpet-shaped tubes connected symmetrically at the small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com