Denitrification collaborative bio-doubling process

A biological multiplication and denitrification technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of effluent water quality not meeting the direct reuse standard, high operating cost, Low operating costs and other issues, to achieve the effect of excellent water discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

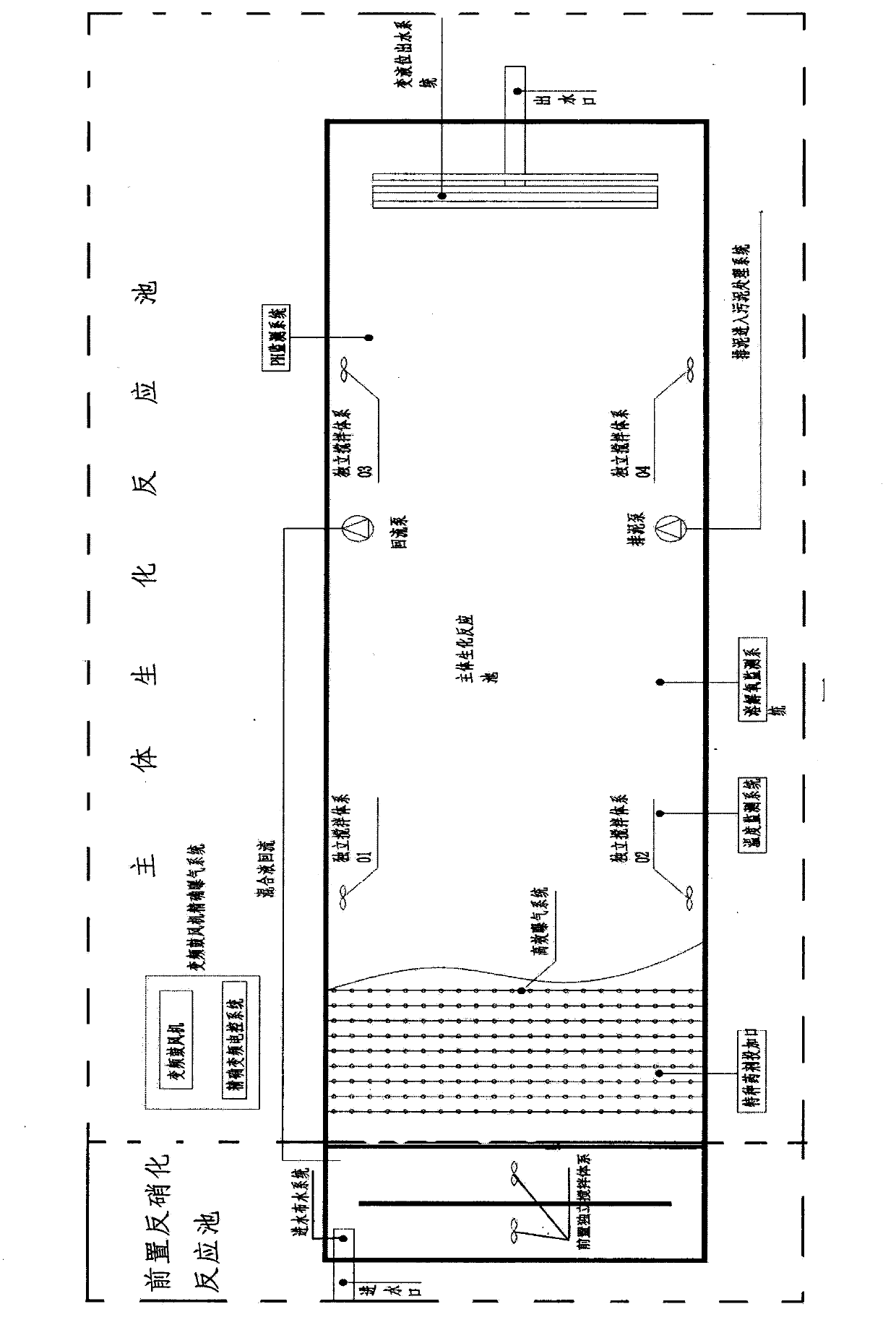

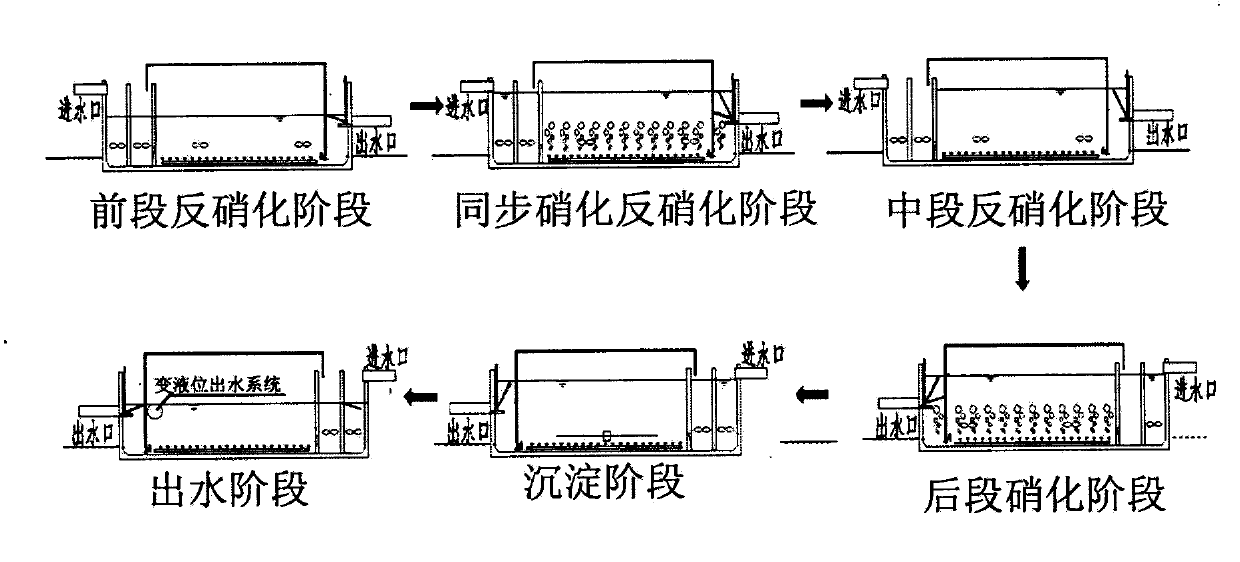

[0027] Such as figure 1 , figure 2 The denitrification synergistic biological multiplication process shown includes two parts: the main system and the auxiliary system; the main system includes the water inlet distribution system, the variable liquid level water outlet system, the frequency conversion blast precision aeration system, the independent stirring system, Pre-denitrification selection tank, main biochemical reaction tank and return pump, sludge pump; auxiliary system includes precise aeration electric control system, independent mixing system, special chemical dosing system, temperature monitoring system, PH monitoring system, dissolved oxygen monitoring system.

[0028] The frequency conversion blower precision aeration system includes a frequency conversion blower and a precision frequency conversion electric control system.

[0029] The independent stirring system includes independent stirring system 01, independent stirring system 02, independent stirring sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com