Method for Optimizing Underpressure in Vacuum Units of Textile Machines for Manufacturing Cross-Wound Packages

A technology for cross-winding bobbins and vacuum devices, which can be used in textiles and papermaking, transportation and packaging, thin material handling, etc., and can solve problems such as increasing vacuum requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

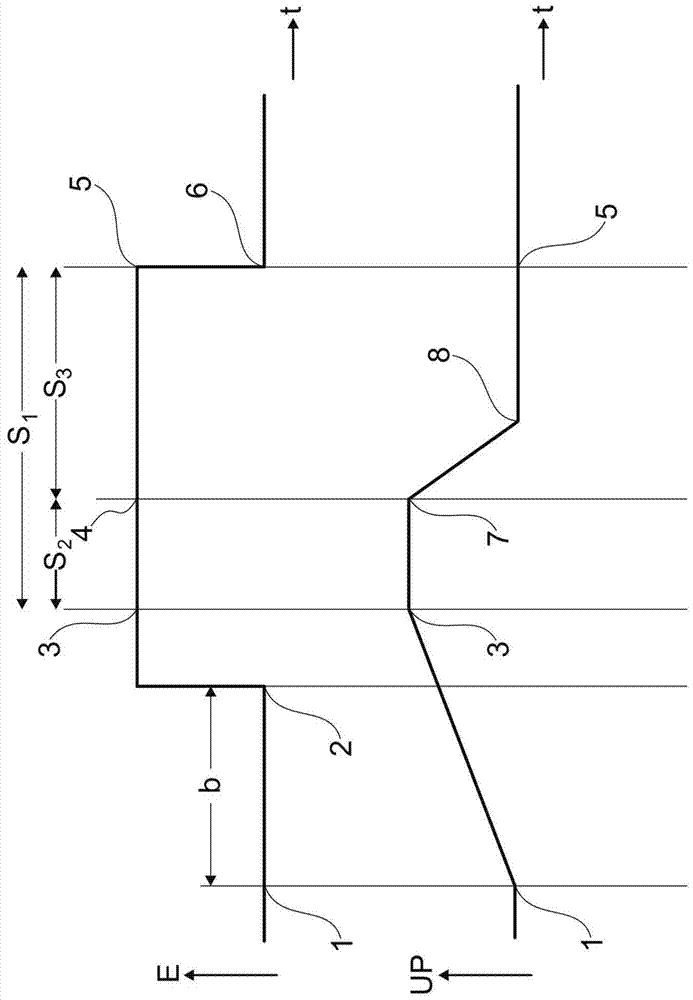

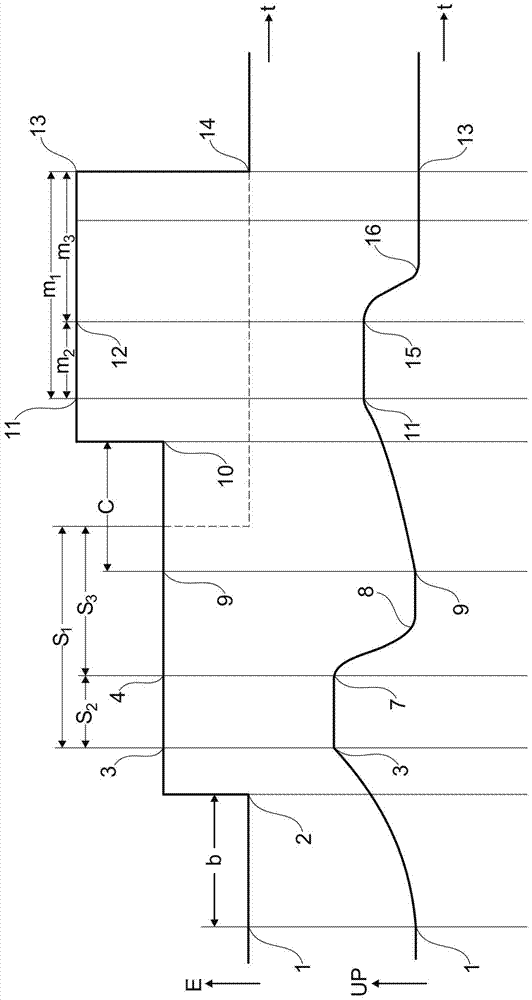

[0020] figure 1 The event E curve plotted against time t at the station is shown. Event E is in this example a yarn break and yarn break repair on the winder. A yarn break occurs at time 1. The cross-wound bobbin on which the yarn is wound is lifted by the bobbin drive roller driving it and braked for a time b. When at moment 2, the cross-winding bobbin is stationary, the switchover to broken yarn repair begins. At moment 3, the suction nozzle is in position to pick up the veil from the cross-winding bobbin, while the clamping bobbin under negative pressure catches the ground yarn from the feed bobbin in the unwinding position. Period s1 includes all sub-processes up to the end of the event, that is to say the end of the yarn connection cycle. Only during period s2 is there a higher vacuum requirement for successful yarn capture. Signaling at time 4 indicates that the veil has been successfully captured and no higher negative pressure is required. In the period s3, both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com