Novel automobile hub

An automobile wheel hub and a new type of technology, applied in the direction of wheels, spoked wheels, vehicle parts, etc., can solve the problems of shortening the service life of tires, tire punctures, and inability to drop the temperature, so as to prolong the service life, ensure driving safety, and dissipate heat. The effect of improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

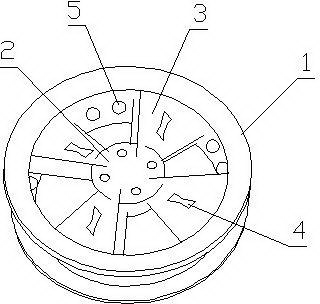

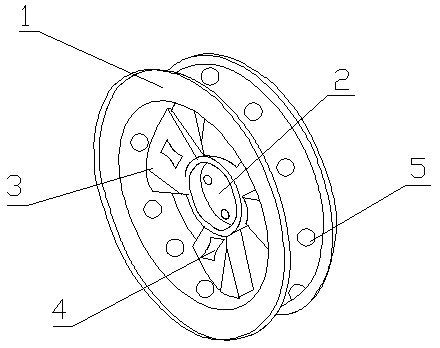

[0014] Such as figure 1 As shown, a new type of automobile hub includes a rim 1, a hub 2, and a spoke 3 connecting the rim 1 and the hub 2. The spoke 3 is fan-shaped, and the spoke 3 at the hub 1 has a width Greater than the width of the spoke 3 at the place connecting the hub 2, the number of spokes 3 is 4, the spokes 3 are evenly distributed radially along the outer circumference of the hub 2, and the outer surface of the spoke 3 is inclined at 15 degrees relative to the side plane of the hub. The middle part of the outer surface of the wheel 3 is provided with a concave U-shaped blind groove 4. The depth of the U-shaped blind groove 4 is 1.5 mm. Between the two spokes 3, there are air holes 5 through the rim 1. The air holes 5 are circular holes. , the inner thickness of the rim 1 is lower than the thickness of its outer edge.

[0015]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com