Water injection high-frequency endotherm knife for operations

A high-frequency electrocautery, surgical technology, applied in the field of medical surgical instruments, can solve the problems of easily damaged and heated small blood vessels, delayed complications, large tissue scope, etc., and achieves clear surrounding anatomical structure, enhanced electrical conductivity, Strong sense of organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

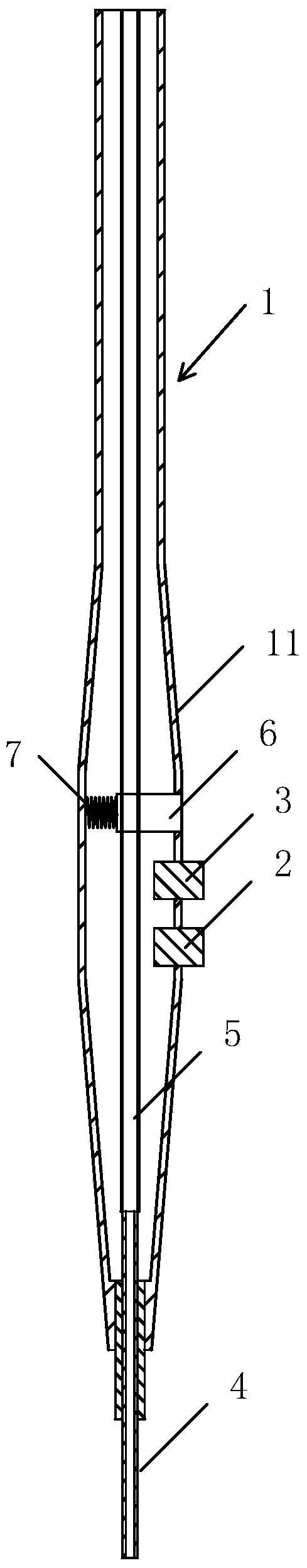

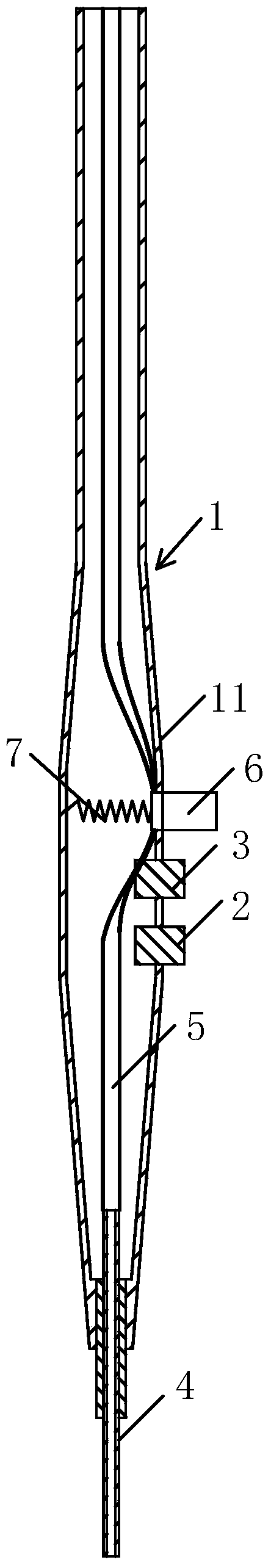

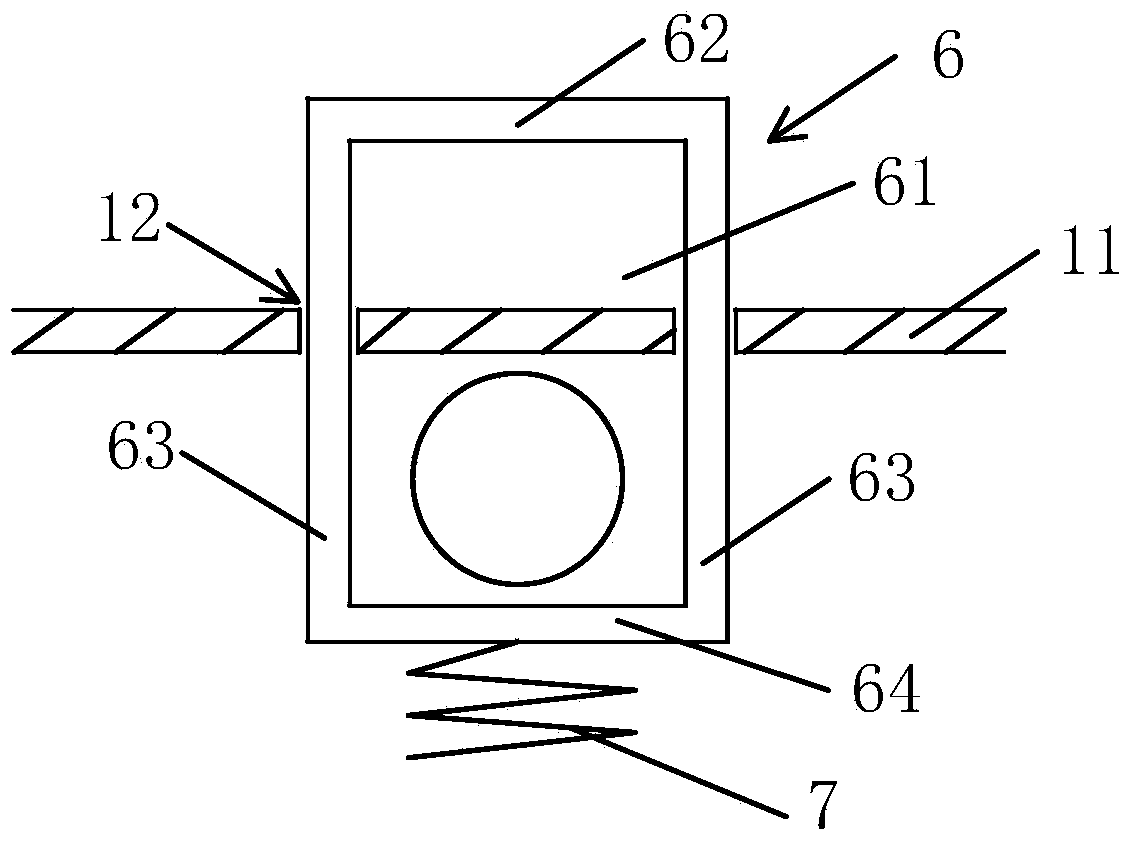

[0046] Such as figure 1 As shown, the water injection high-frequency electric knife for surgery of the present invention includes a housing 1 and a metal electric knife head arranged at one end of the housing, and the metal electric knife head is electrically connected to the circuit board (not shown) located in the housing. To connect, the circuit board is connected to the electric wire (not shown in the figure) arranged at the tail end of the casing, and the electric wire is connected to an electrode terminal of the external high-frequency generator (not shown in the figure). Wherein, the circuit board located in the casing, and the connection method between the circuit board, the metal electric knife head and the electric wires are all known to those skilled in the art, so they will not be described in detail.

[0047] The side wall 11 of the casing is provided with an electric cutting button 2 and an electric coagulation button 3 electrically connected with the circuit boa...

Embodiment 2

[0055] The structure of the water-filled high-frequency electric knife in this embodiment is roughly the same as that in Embodiment 1, except that there is a difference in the arrangement of the metal electric knife head. Embodiment 1 is to replace the metal electric knife head with a metal injection needle, and this embodiment is to retain the metal electric knife head, and add a metal injection needle at the head end of the shell, so that the metal injection needle and the water injection hose One end is connected, and the water injection hose sprays the injection liquid through the metal injection needle. In addition, the metal injection needle can also be retractable, so that the metal injection needle can be stretched out during the operation, the water injection control button can be pressed, the injection fluid is sprayed on the local tissue, and then the metal injection needle can be retracted, and then the metal injection needle can be retracted like using an ordinary ...

Embodiment 3

[0057] The structure of the water-injection high-frequency electric knife in this embodiment is roughly the same as that in Embodiment 1, except that this embodiment uses a water-injection control paddle as a water-injection switch structure for controlling the on-off of the water-injection liquid in the injection hose. Such as Figure 4 As shown, the water injection control paddle 8 is rotatably connected to the side wall 11 of the casing through a rotating shaft 9. When the water injection control paddle is turned to be perpendicular to the side wall of the casing, the water injection control paddle presses against the injection hose. The flow of injection liquid in the injection hose is hindered. When the water injection control paddle is moved to incline with the side wall of the housing, the injection hose is no longer pressed, and the injection liquid in the injection hose can flow smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com