Minitype capsule coffee machine

A technology of coffee machines and capsules, which is applied in the field of coffee processing devices, can solve the problems of capsule coffee machines with complex structure, large volume, and inability to meet the volume requirements of capsule coffee machines, and achieve simple structure, small volume, and satisfactory volume. required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

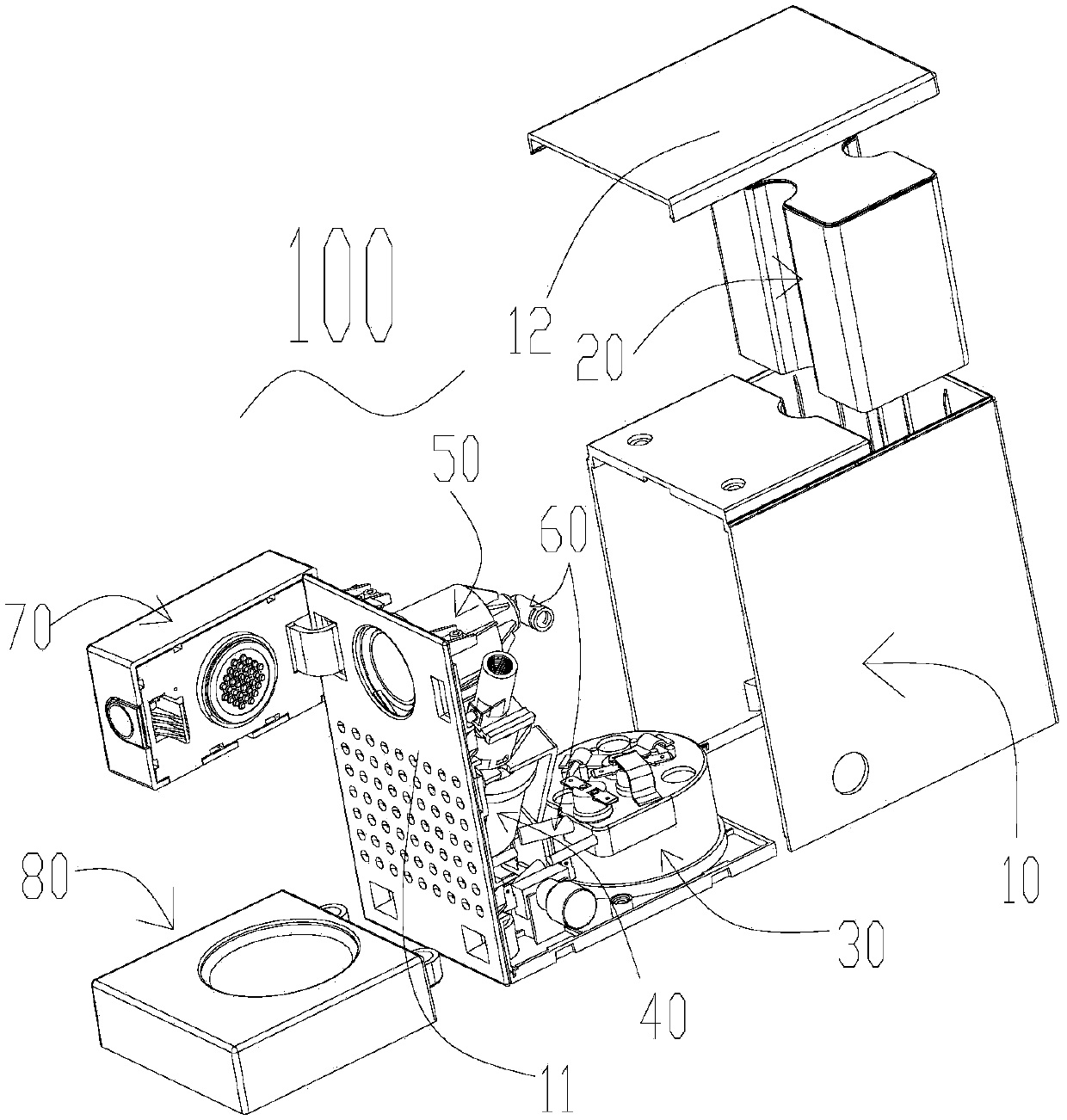

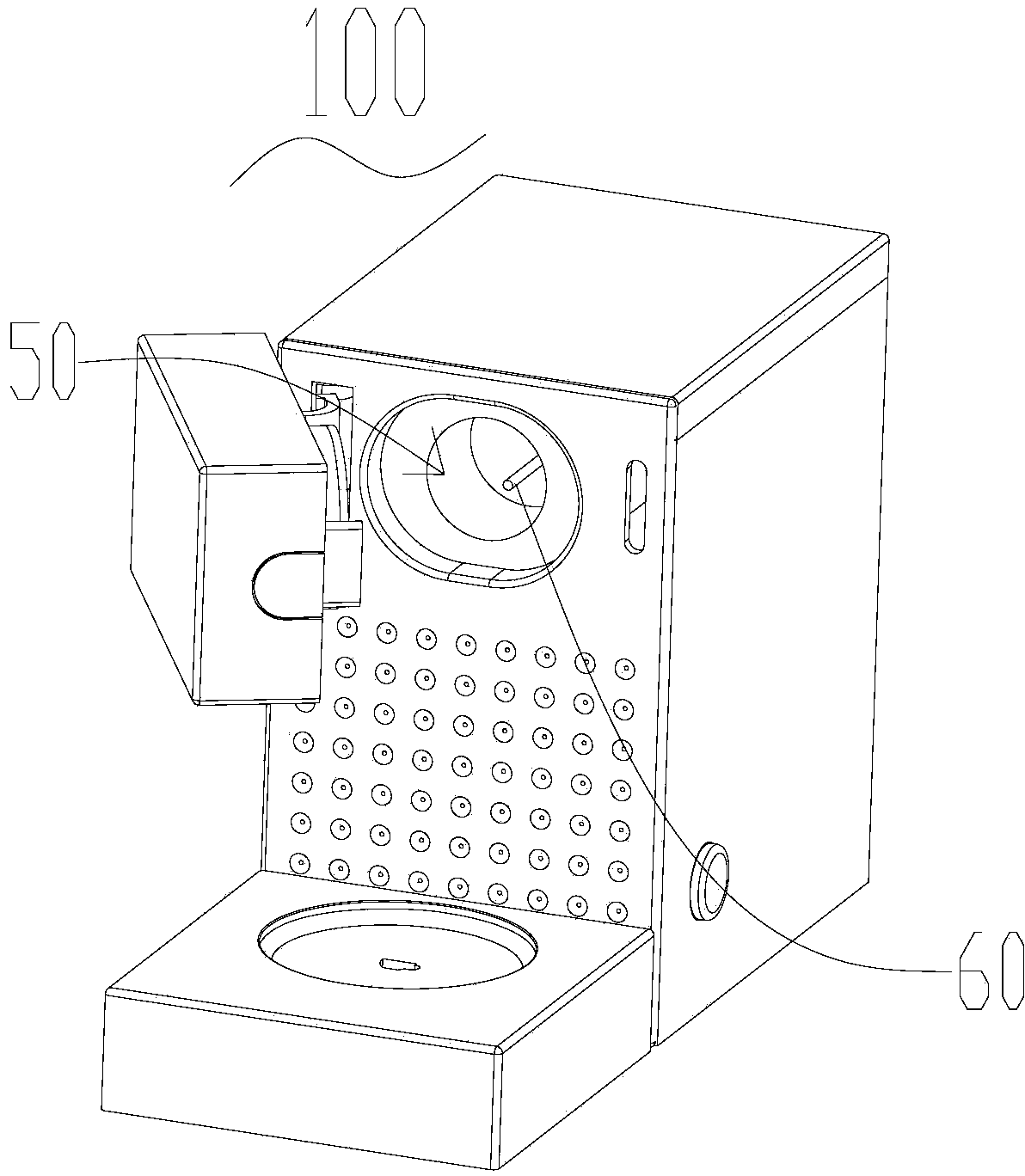

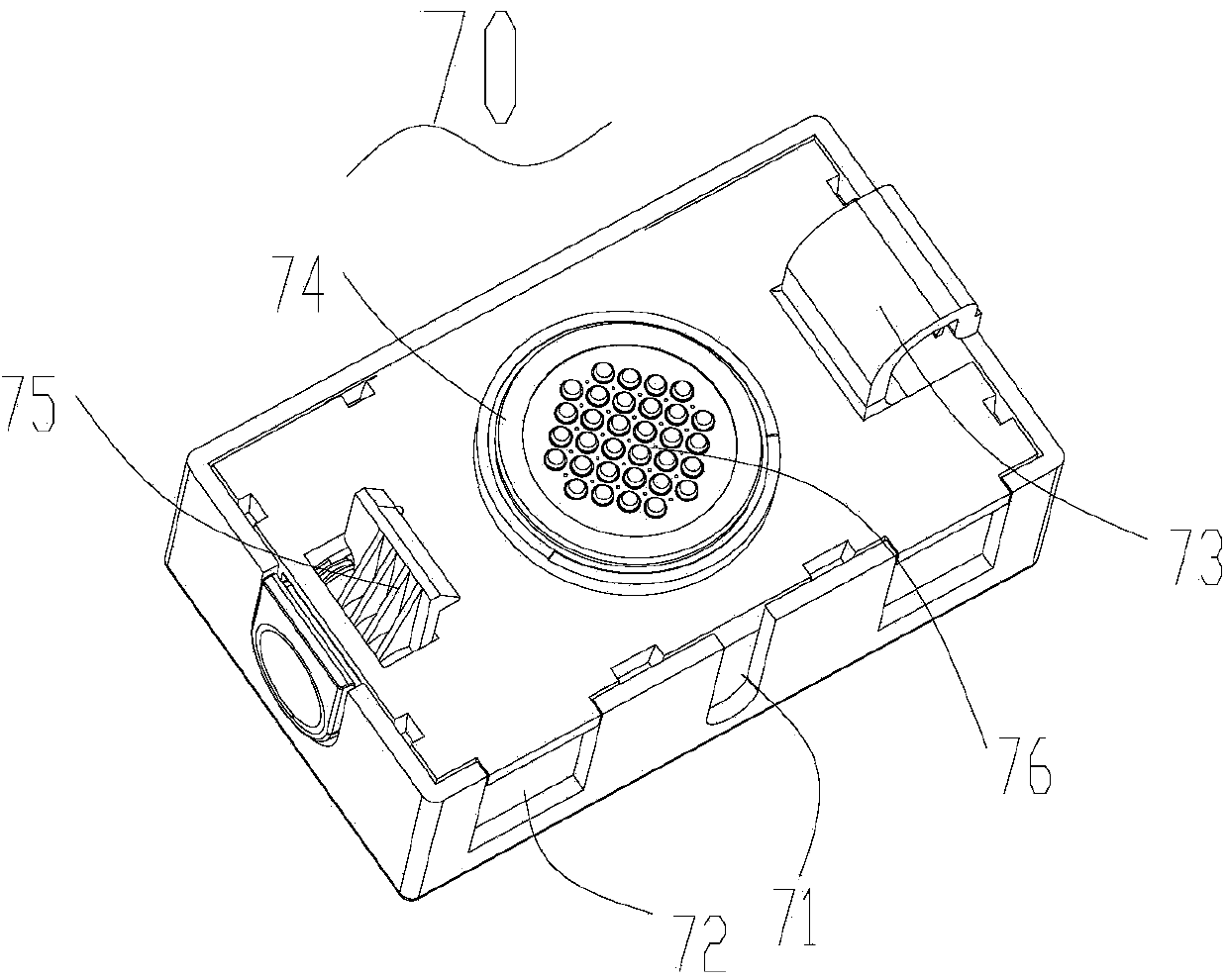

[0027] see figure 1 , figure 2 , the mini capsule coffee machine 100 provided by the preferred embodiment of the present invention includes a square housing 10, a water tank 20 located inside the housing 10, a boiler 30, a water pump 40, a capsule accommodating chamber 50, a conduit 60 and a The brewer 70 and the drip box 80 outside the housing 10 .

[0028] The housing 10 is square, and the square housing 10 has a first side wall 11 perpendicular to the ground, and the side of the first side wall 11 close to the ground has at least one first opening 12 for fixing the drip box 80 . It can be understood that the housing 10 of the capsule coffee machine 100 in this embodiment is arranged in a square shape to facilitate the installation of parts inside the housing 10 of the capsule coffee machine 100, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com