On-line diagnosis method for mechanical installation faults of rotor craft

A technology of a rotorcraft and a diagnosis method, which is applied in the field of on-line diagnosis of mechanical installation faults of the rotorcraft, can solve problems such as low accuracy, affecting the flight control accuracy of the rotorcraft, and crash failures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

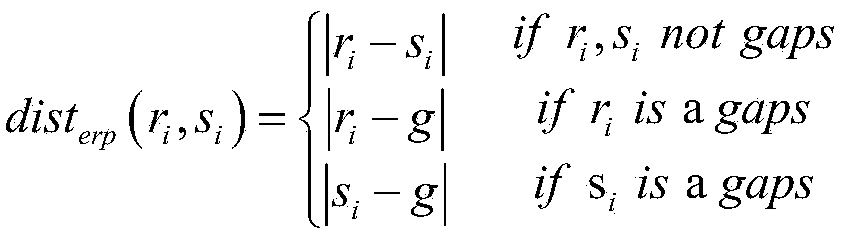

Method used

Image

Examples

Embodiment Construction

[0032]The mechanical installation fault calibration of the existing rotorcraft is carried out by offline mechanical debugging. The installation error of the rotorcraft is checked and corrected by mechanical methods such as measuring the wheelbase. The accuracy of this type of mechanical installation error diagnosis method is low. The vibration of the aircraft itself and changes in the surrounding environment during flight may easily cause changes in the mechanical structure of the rotorcraft, directly affect the flight control accuracy of the rotorcraft, and even cause crashes. In order to solve the above problems, the present invention adopts a method for online diagnosis of mechanical installation faults. The specific implementation method is as follows: when the rotorcraft takes off for more than 1 minute and completes hovering, pitching, rolling, and lifting actions, according to The following analysis steps carry out the flight status analysis on the flight parameters of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com