Device and method for measuring minimum diameter of diameter shrinkage portion of tensile sample after fracture

A technique for tensile specimen and diameter measurement, applied in the field of mechanical test technology, mechanical measurement, and sensor, and can solve problems such as being unsuitable for measuring the smallest diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing.

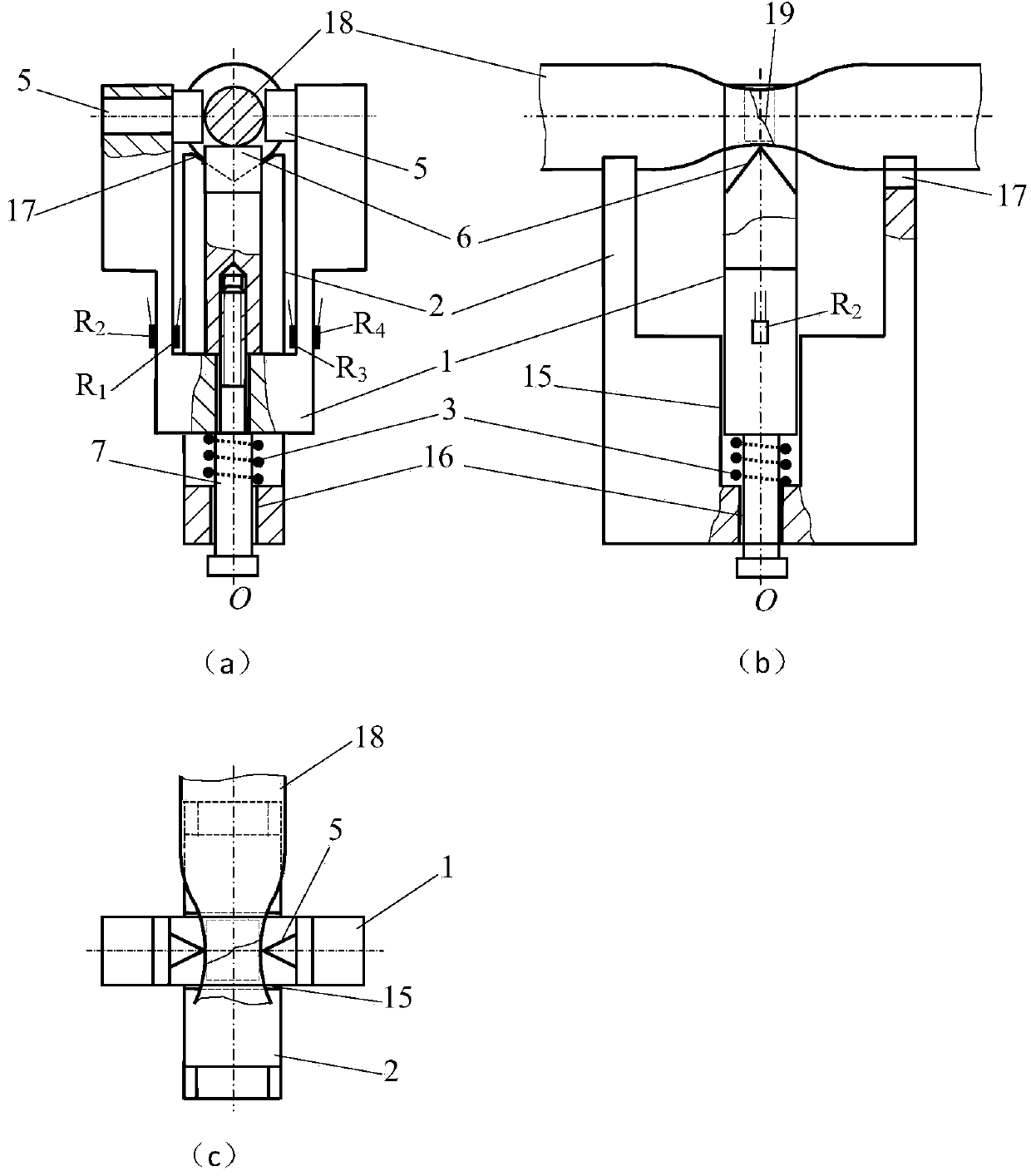

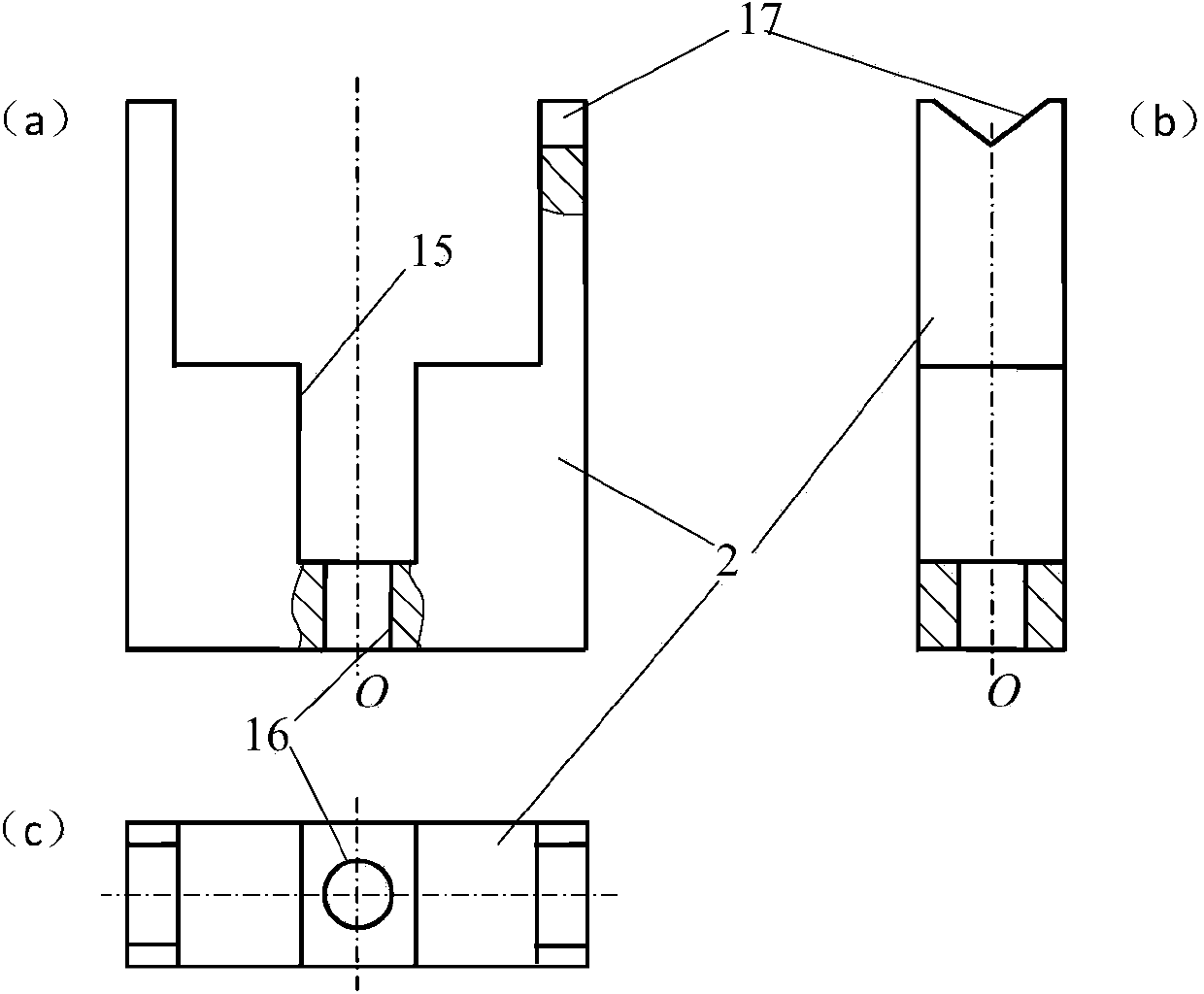

[0041] refer to figure 1 — Figure 8 , the device for measuring the minimum diameter of the shrinkage part of the tension sample after fracture of the present invention includes a sensor 1, a support 2, a compression spring 3, a standard device and a data acquisition instrument;

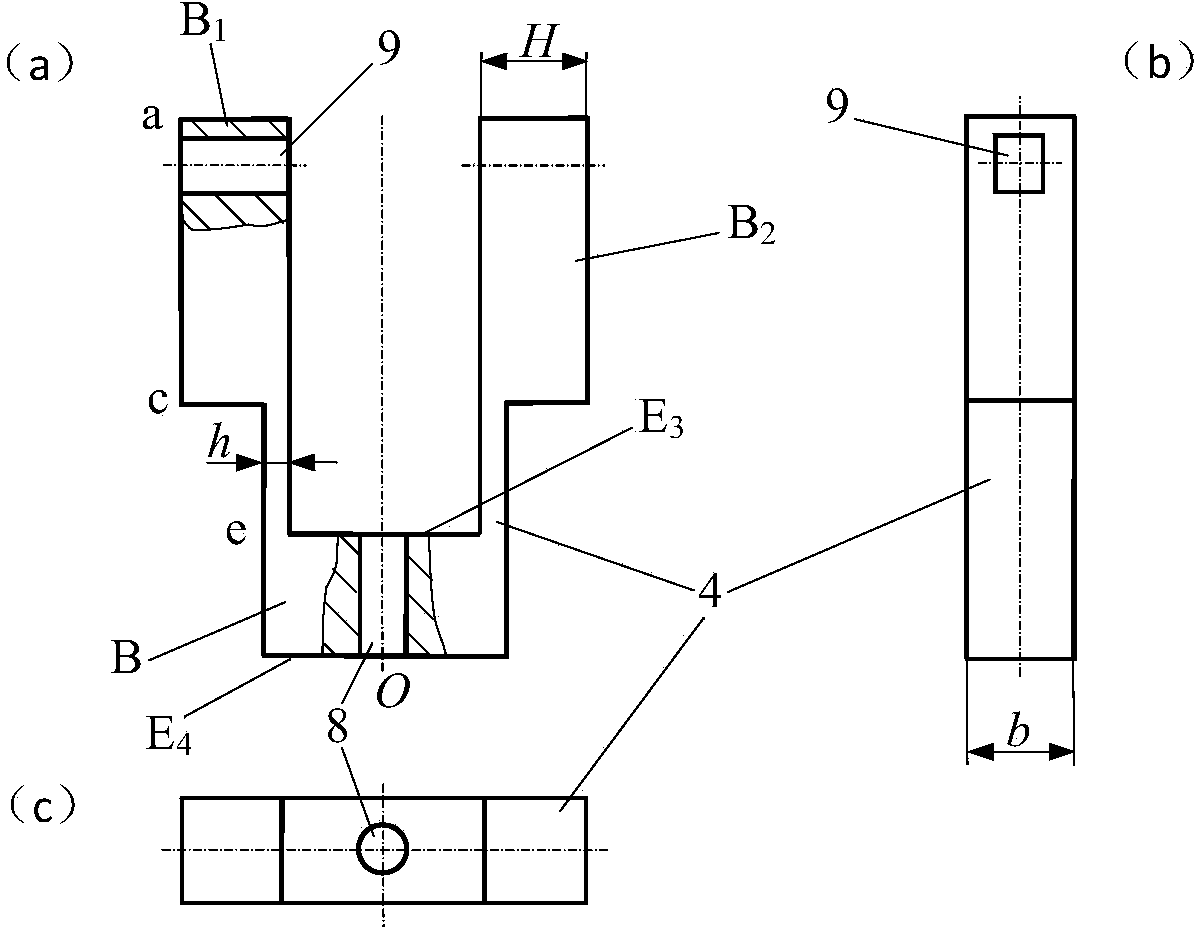

[0042] The sensor 1 has a U-shaped elastic body 4, two blade blocks 5, a positioning column 6, a guide rod 7 and four uniaxial resistance strain gauges R 1 , R 2 , R 3 and R 4 ; U-shaped elastic body 4 is symmetrical in shape, and its structure includes a base B and a left variable cross-section cantilever beam B fixedly connected to both ends of the base B 1 and the right variable section cantilever beam B 2 , the left cantilever beam with variable cross-section B 1 and the right variable section cantilever beam B 2 The cross-section is rectangular, and from the free end a to the root e, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com