soot blower

A soot blower and soot blowing tube technology, which is applied in the fields of electric power equipment and petrochemicals, can solve problems such as rising costs of enterprises, unfavorable long-term development, and affecting service life, so as to prolong service life, improve soot blowing efficiency, and reduce the impact of high temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

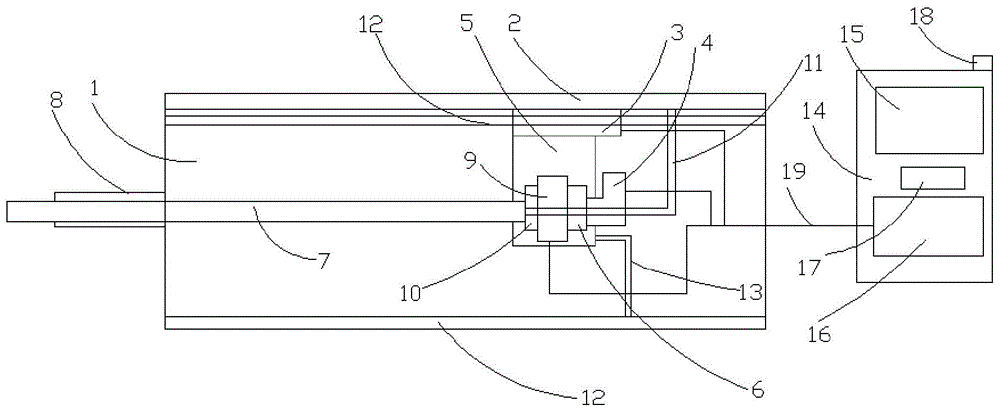

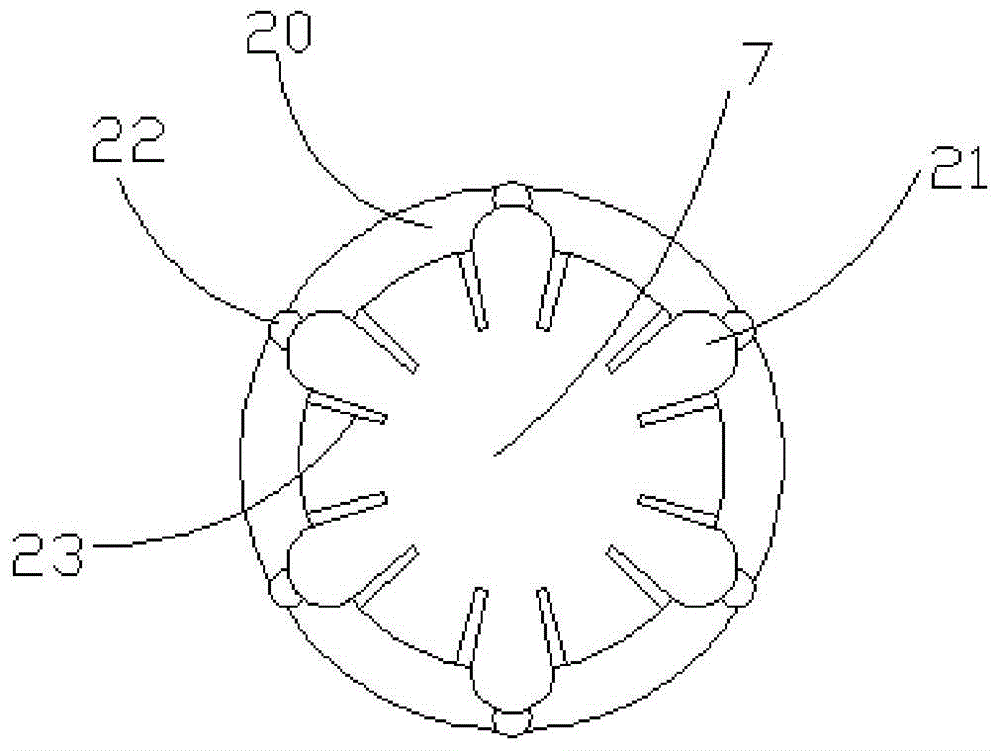

[0018] Such as figure 1 with figure 2 As shown, the present invention relates to a soot blower, which is characterized in that it includes a fixed box 1, a pair of horizontally arranged guide rails 2 are provided on the upper part of the fixed box 1, and a drive motor 3 is provided on the guide rail 2 And the movable table 5 of the rotating motor 4, an input shaft and a double output shaft reducer 6 are provided at the output end of the rotating motor 3, and the output shafts are respectively connected to the soot blowing pipe 7, and the front end of the fixed box 1 A protection tube 8 is provided on the outer wall. The inside of the protection tube 8 allows the soot blowing tube 7 to operate freely back and forth; the two soot blowing tubes 7 are connected to an air pump 10 with a solenoid valve 9 together, and the air pump 10 is connected to an air pipe 11 , The air pipe 11 is arranged on the upper part of the fixed box 1 through the shelf 12; the movable platform 5 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com