Novel three-way reversing valve

A three-way reversing valve, a new type of technology, used in fluid pressure actuating devices, servo motor components, mechanical equipment, etc., can solve problems such as low service life, air leakage or air leakage, and achieve high operating pressure and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

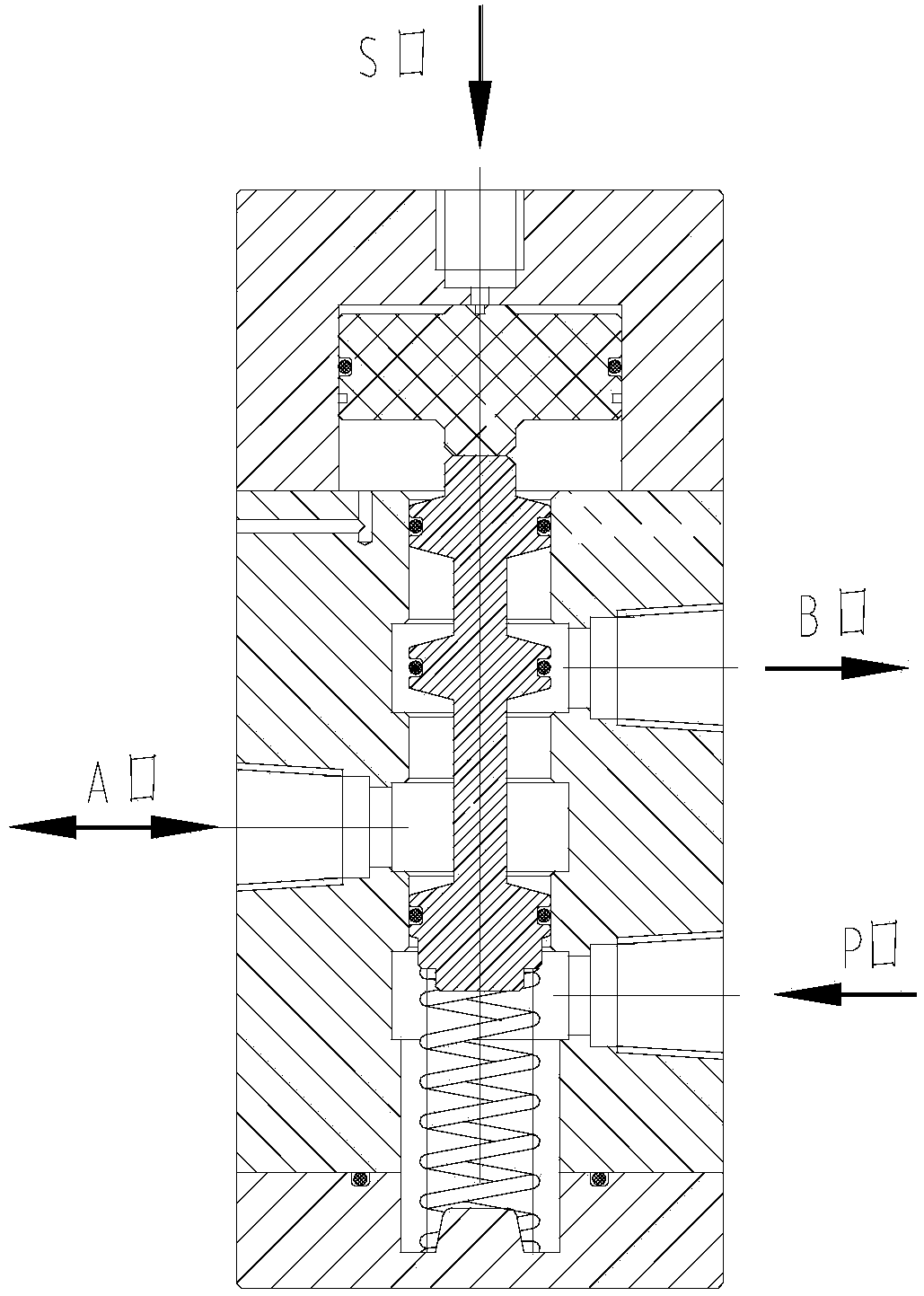

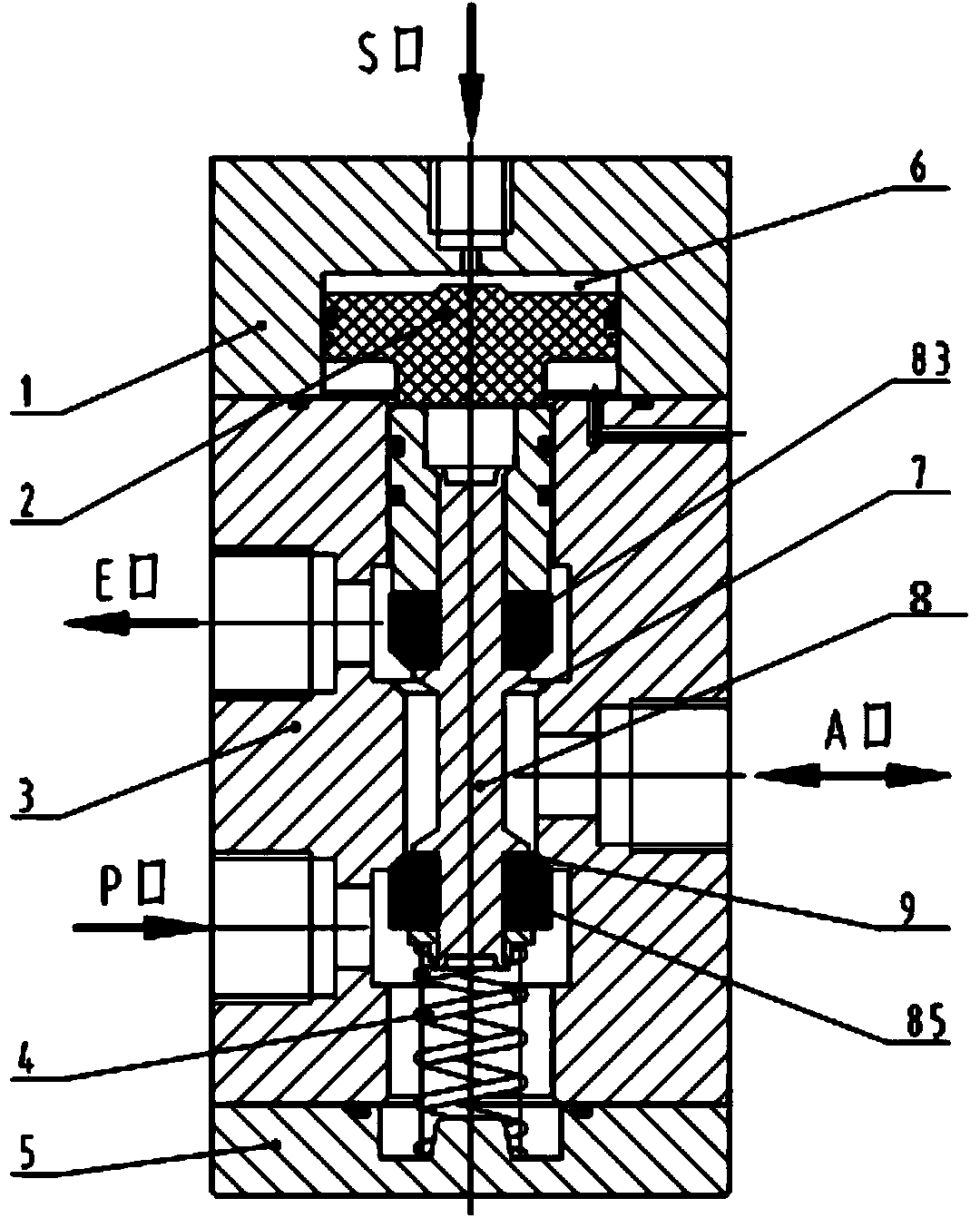

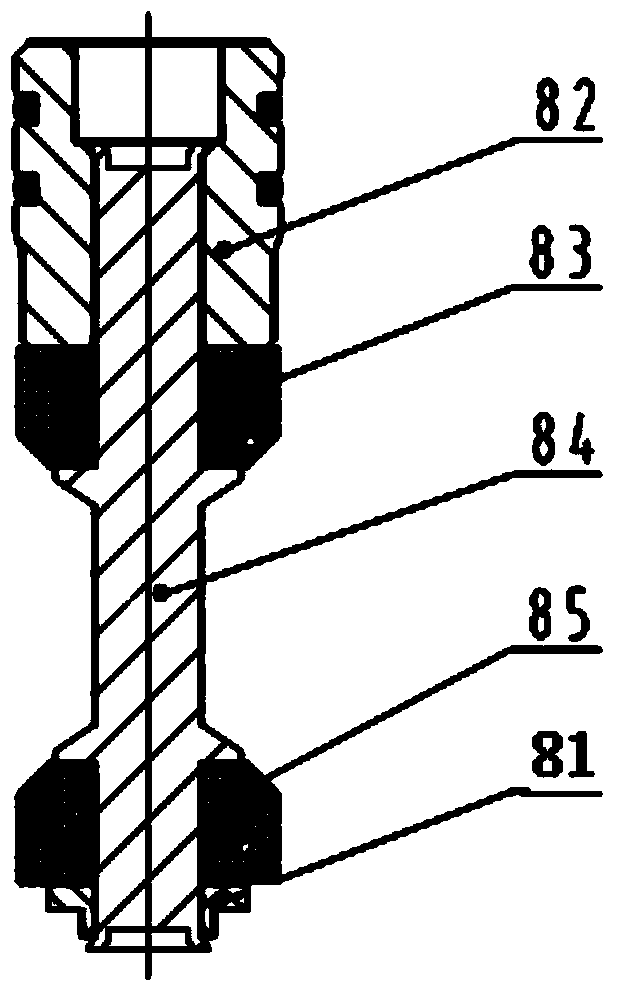

[0014] like figure 2 , 3 As shown, the present invention is a new type of three-way reversing valve, including a hollow reversing chamber 3, and an air inlet, an air outlet and a reversing port are respectively opened on the side of the reversing chamber 3, and the reversing The port is located between the air inlet and the air outlet, a piston chamber 1 is installed at the top of the reversing chamber 3, a signal inlet is opened on the piston chamber 1, and a base 5 is installed at the bottom end of the reversing chamber 3; A guide piston 82 is installed in the reversing chamber 3 , the top of the guide piston 82 is connected with an air control piston 2 , the air control piston 2 is located in the air pressure chamber 6 in the middle of the piston chamber 1 , and the air control piston 2 is The outer wall is hermetically sealed with the inner wall of the piston cavity 1; an annular first boss-type sealing valve seat 7 is arranged on the inner wall of the reversing cavity 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com