Volute changeable type marine self-priming centrifugal pump

A volute type, centrifugal pump technology, applied in non-variable volume pumps, components of pumping devices for elastic fluids, pumps, etc., can solve the problem of unreasonable force on the pump shaft and pump body, occupying space, Short life and other problems, to improve the operating conditions of the pump, increase the service life of the pump, and save the axial position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

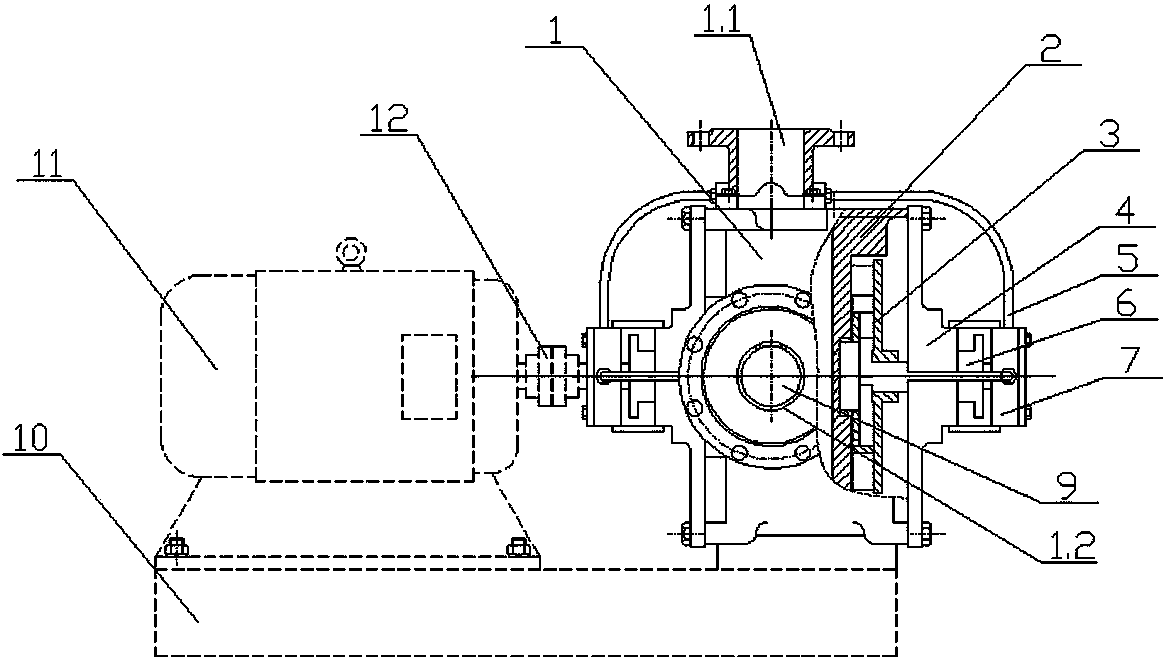

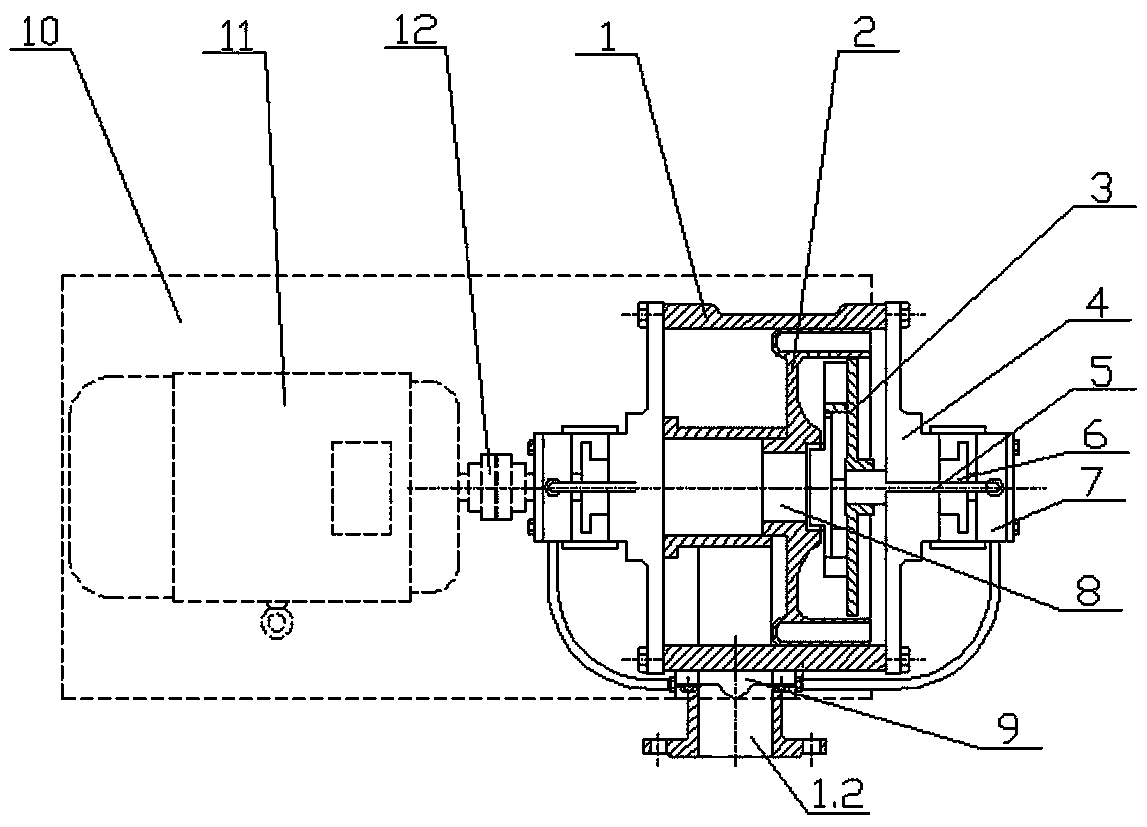

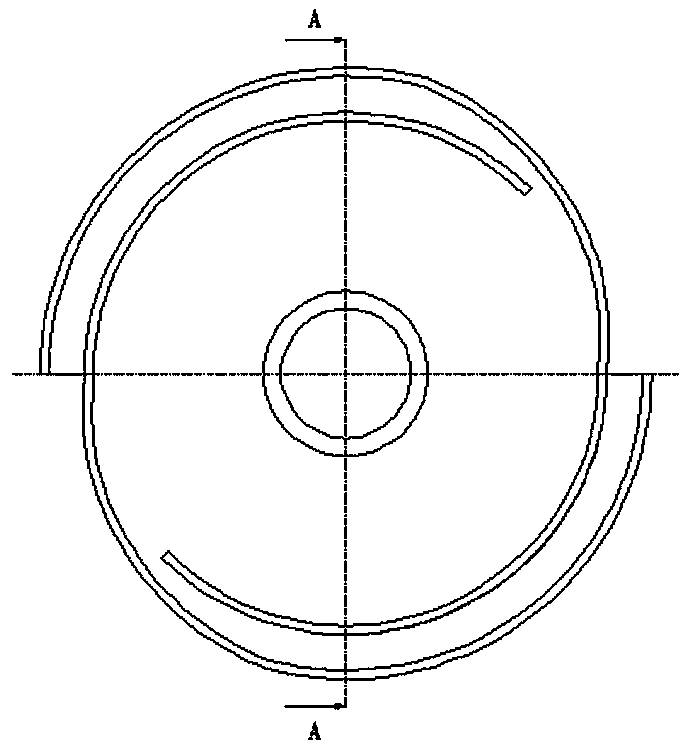

[0021] figure 1 The replaceable volute marine self-priming centrifugal pump shown is a horizontal single-stage single-suction centrifugal pump, which consists of pump body 1, volute 2, impeller 3, pump cover 4, water pipe 5, shaft seal 6. The shaft seat 7, the pump shaft 8 and the valve plate 9 are composed. The pump body 1 is a horizontal casing with a cylindrical through hole in the inner cavity, and is installed on the base 10 in a horizontal position. The pump cover 4 is respectively installed at the left and right ends of the axial through hole of the pump body 1, and the top of the outer wall is provided with a pump outlet 1.1 that opens upward and penetrates the inner cavity of the pump body 1, and is 90° away from the left side of the pump outlet 1.1. 0 A pump inlet 1.2 facing outward and penetrating the inner cavity of the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com