Motor vehicle drive train with hydraulic retarder

A drive system and motor vehicle technology, applied in the direction of hydraulic brakes, liquid resistance brakes, brakes, etc., can solve problems such as extremely large structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

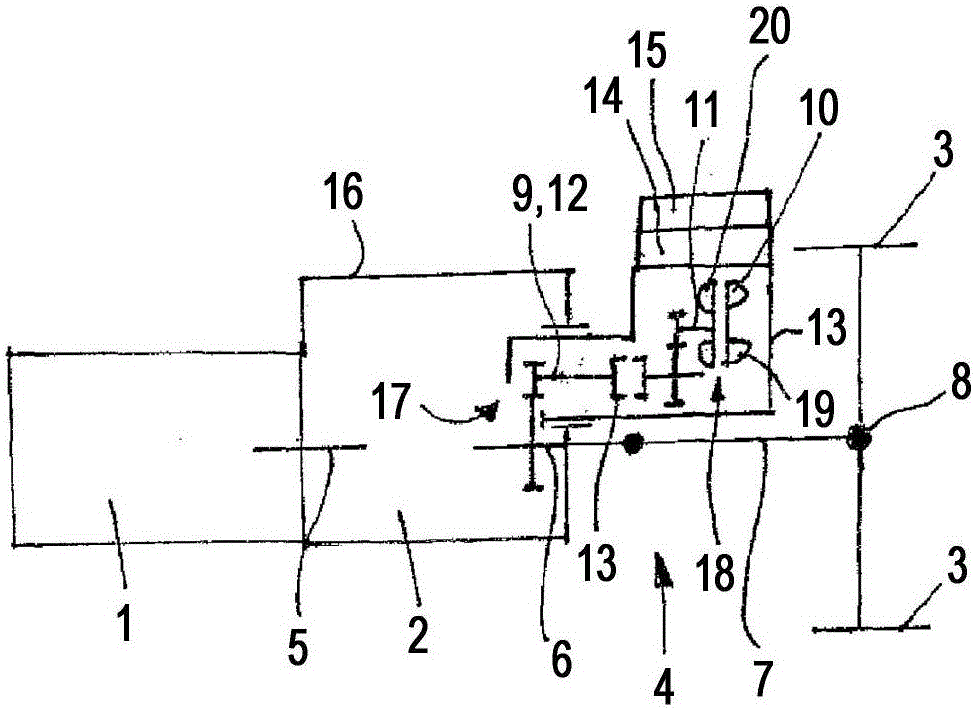

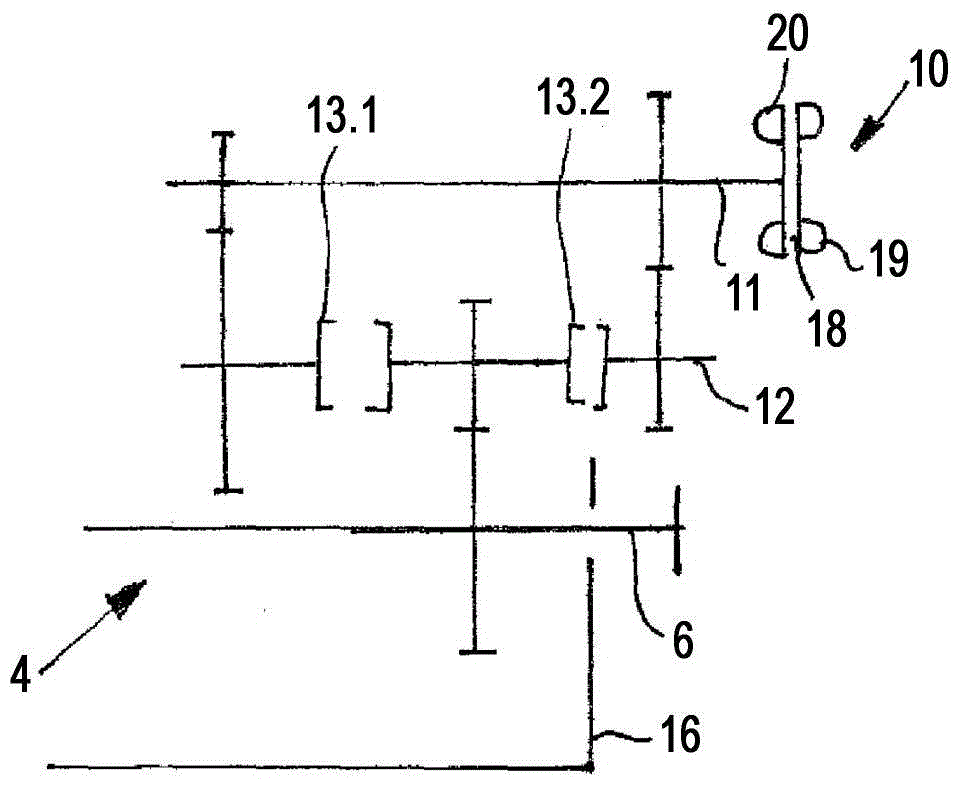

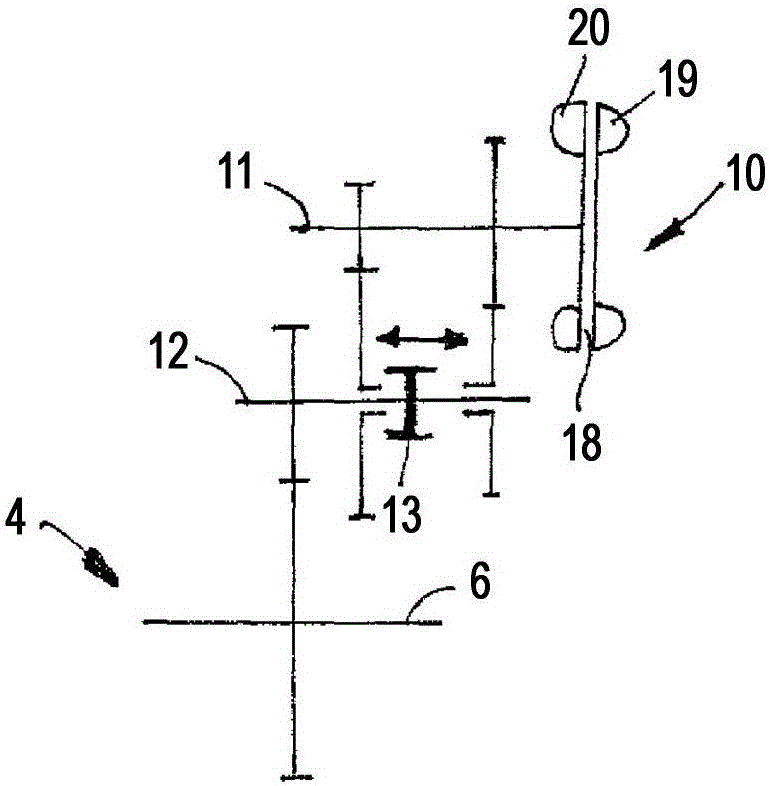

[0020] figure 1 2 schematically shows a motor vehicle drive train according to the invention with a drive motor 1 , a transmission 2 , in particular a cascade transmission or a continuously variable transmission, and drive wheels 3 driven by the drive motor 1 via the transmission 2 . Correspondingly, the main road 4 of the drive train of the motor vehicle extends from the drive motor 1 via the transmission input shaft 5 , the transmission output shaft 6 and the usual cardan shaft 5 on the differential drive 8 to the driven wheels 3 .

[0021] The transmission 2 has an auxiliary drive train on the secondary side with an auxiliary output shaft 9 which is drivingly connected to the transmission drive shaft 6 via a spur gear pair. With regard to the connection of the hydraulic gear unit 10 or its rotor shaft 11 , the auxiliary output shaft 9 is at the same time the intermediate shaft 12 of the connection according to the invention.

[0022] The countershaft 12 has a disconnect cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com