Lithium ion battery aging method

A lithium-ion battery, battery technology, applied in the manufacture of secondary batteries, electrochemical generators, electrolyte batteries, etc., can solve the problems of affecting battery life, low production efficiency, slow interface reaction, etc., to achieve excellent cycle performance, improve production Efficiency, effect of short aging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

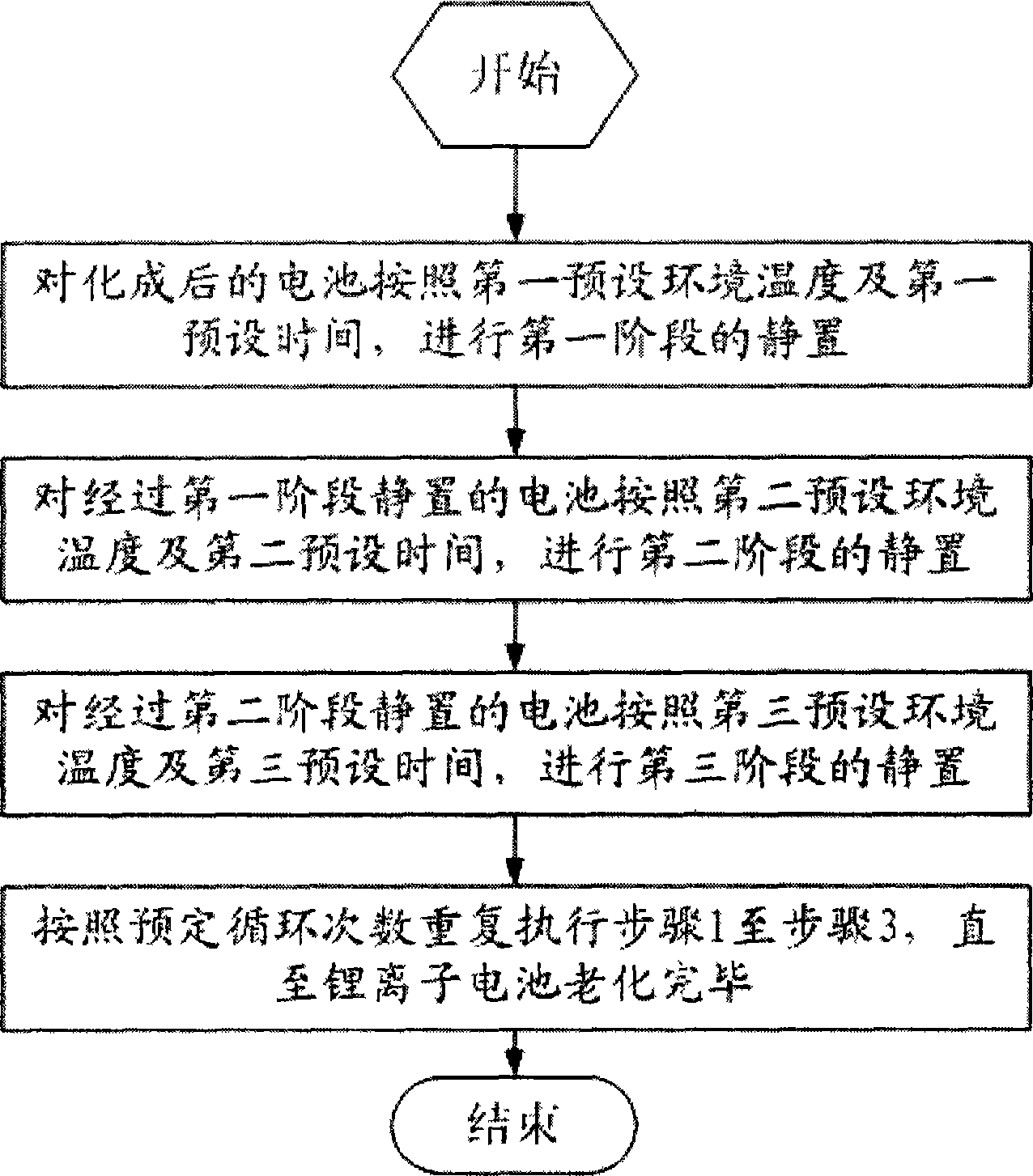

[0026] Step 1: Perform the first stage of standing for the battery after formation, that is, stand at 40°C for 24 hours;

[0027] Step 2: Carry out the second stage of standing for the battery after the first stage of standing, that is, standing at 25°C for 72h;

[0028] Step 3: Perform the third stage of standing for the battery after the second stage of standing, that is, stand at -10°C for 48 hours, and the aging of the lithium ion battery is completed.

[0029] After aging the lithium-ion battery by this method, the following data are obtained: the internal resistance is 3.5mΩ, the first discharge capacity is 8.084Ah, the 200th discharge capacity is 7.776Ah, and the capacity retention rate at the 200th cycle is 96.2%.

Embodiment 2

[0031] Step 1: Perform the first stage of standing for the battery after formation, that is, stand at 45°C for 48 hours;

[0032] Step 2: Carry out the second stage of standing for the battery after the first stage of standing, that is, standing at 25°C for 48h:

[0033] Step 3: Perform the third stage of standing for the battery that has passed the second stage of standing, that is, standing at -10°C for 72 hours, and the aging of the lithium-ion battery is complete.

[0034] After aging the lithium-ion battery by this method, the following data are obtained: the internal resistance is 3.4mΩ, the first discharge capacity is 8.065Ah, the 200th discharge capacity is 7.750Ah, and the capacity retention rate at the 200th cycle is 96.1%.

Embodiment 3

[0036] Step 1: Perform the first stage of standing for the battery after formation, that is, stand at 45°C for 24 hours;

[0037] Step 2: Carry out the second stage of standing for the batteries that have passed the first stage of standing, that is, standing at 15°C for 24 hours;

[0038] Step 3: Carry out the third stage of standing for the battery after the second stage of standing, that is, standing at -20°C for 48h;

[0039] Step 4: Repeat step 1 to step 3 once until the aging of the lithium-ion battery is complete.

[0040] After aging the lithium-ion battery by this method, the following data are obtained: the internal resistance is 3.3mΩ, the first discharge capacity is 8.055Ah, the 200th discharge capacity is 7.781Ah, and the capacity retention rate at the 200th cycle is 96.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Internal resistance | aaaaa | aaaaa |

| First discharge capacity | aaaaa | aaaaa |

| Internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com