Control cable of flat structure

A control cable and flat technology, applied in the field of control cables with flat structure, can solve the problems of poor toughness, brittle cracking, affecting the performance of the cable, and achieve the effect of improving the performance, good insulation and isolation, and strong practical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

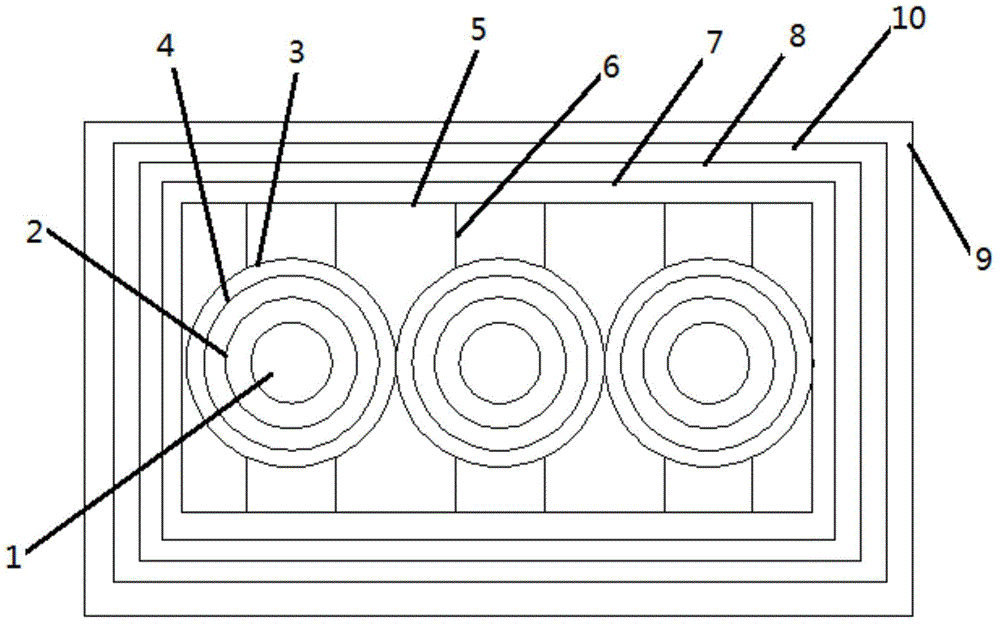

[0014] see figure 1 , a control cable with a flat structure, comprising a plurality of wires 1, the plurality of wires 1 are arranged horizontally side by side and the plurality of wires are respectively covered with inner and outer double-layer nitrile rubber insulating layers 2 and 3, A reinforcing layer 4 woven with nylon fibers is arranged between the inner and outer double-layer nitrile rubber insulating layers 2 and 3, and the inner and outer double-layer nitrile rubber insulating layers 2 and 3 are jointly coated with high flame retardant. The isolation layer 5 formed by the overlapping and wrapping of the fiber tapes, the insulating layer 5 formed by the overlapping and wrapping of the high flame-retardant fiber tapes is provided with a rubber skeleton 6 between the conductors 1 and the isolation layer 5, and the high flame-retardant fiber tapes are overlapped and wound. The isolation layer 5 formed by the package is sequentially covered with a galvanized steel wire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com