Method for measuring material loss factor

A technology of loss factor measurement and loss factor, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc., can solve problems such as material loss factor, and achieve the effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The test device and method in this embodiment are used to measure the material loss factor of a soft damping layer containing a cavity. The measurement method includes the following steps:

[0038] Step 1: In this embodiment, two steel plates of the same size are used, the length, width and thickness are 1.7m, 1.5m, and 5.5mm respectively, and a layer of 3cm material to be tested is laid on one of the steel plates to form a composite damping plate;

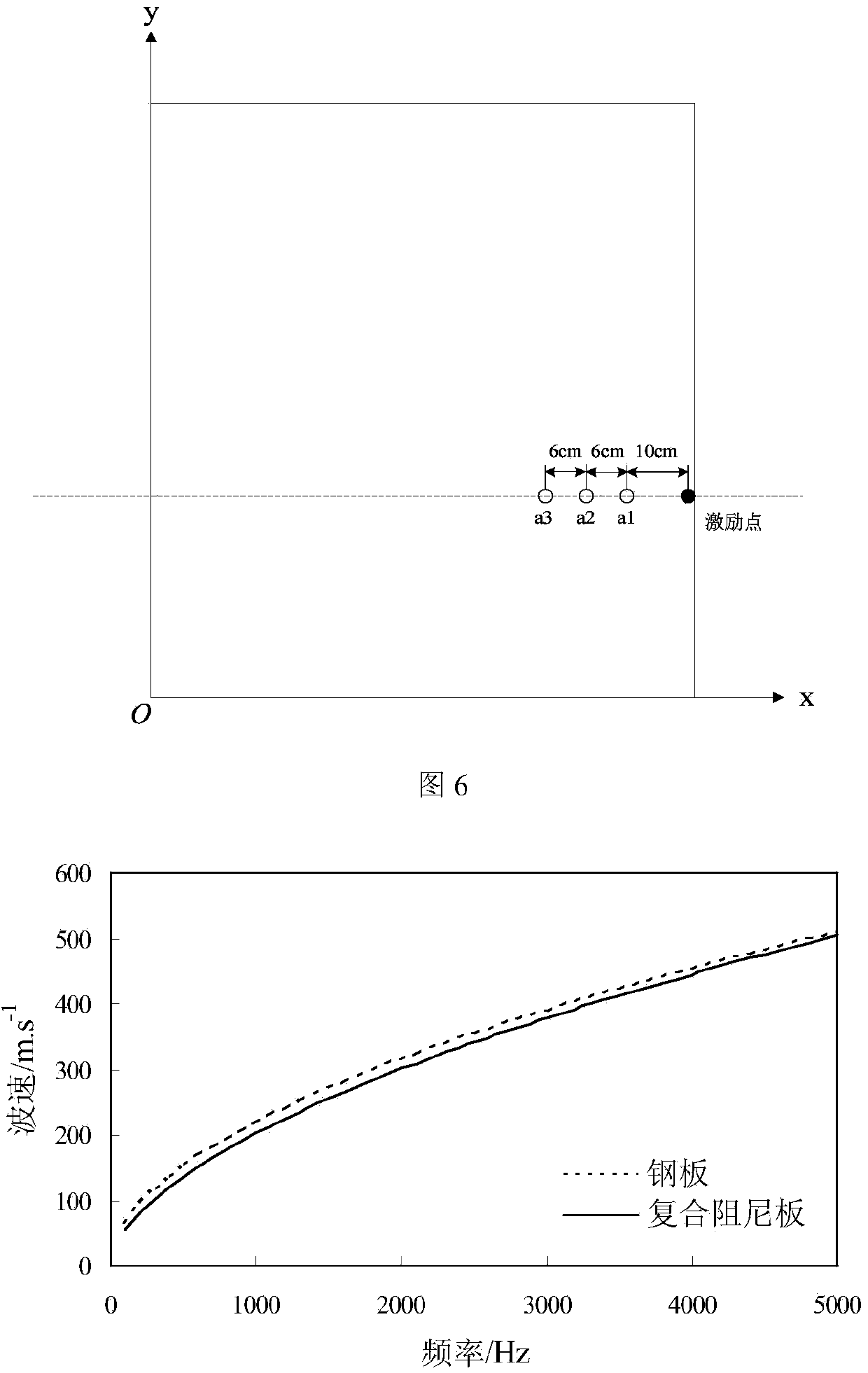

[0039] Step 2: Refer to Image 6 , paste three acceleration sensors on one side of the metal surface of the composite damping plate, the exciter forms excitation points on one side of the metal surface of the composite damping plate, the three measuring points and the excitation point are on a straight line, the test system is as follows Figure 4 shown;

[0040] Will figure 2 The pulse signal with the frequency f shown is input to the vibrator, and the bending wave signals at 3 measuring points on the composite damping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com