Bullet type flow stabilizer

A technology of flow stabilizer and warhead, which is used in instruments, measurement of flow/mass flow, liquid/fluid solid measurement, etc., can solve problems such as inability to accurately measure fluid flow rate, increase in fluid pulsation amplitude, and impact on data accuracy, and achieve structural Novel, improved accuracy, and the effect of accurately measuring fluid flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

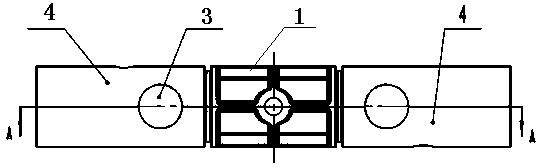

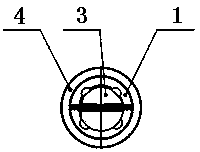

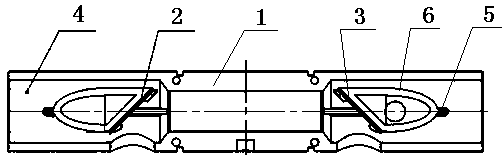

[0025] Embodiment 1: as attached figure 1 , 2 , Shown in 3, a bullet-type current stabilizer is provided with a steady flow pipe body 1, a reflector frame 2, a reflector 3 and a reflection chamber body 4, and the two ends of the flow stabilization pipe body 1 are respectively provided with a reflection chamber pipe body 4, the reflecting cavity tube body 4 is provided with a reflector frame 2, the center line of the reflector frame 2 intersects with the center line of the steady flow tube body 1, and the reflector frame 2 is connected to the reflector cavity through the reflector bracket 5 The pipe body 4 is fixedly connected, and a reflector 3 is installed on one side of the reflector frame 2, and the two reflectors 3 are opposite, and it is characterized in that the other side of the reflector frame 2 is provided with a bullet-shaped fluid 6, and the bullet-shaped stabilizer The bottom end of the fluid 6 is an inclined plane, and the bullet-shaped stabilizing fluid 6 is fi...

Embodiment 2

[0026] Embodiment 2: as attached figure 1 , 6 , Shown in 7, a bullet type current stabilizer is provided with a steady flow tube body 1, a reflector frame 2, a reflector 3 and a reflective cavity tube body 4, and the two ends of the stable flow tube body 1 are respectively provided with a reflective cavity tube body 4, the reflecting cavity tube body 4 is provided with a reflector frame 2, the center line of the reflector frame 2 intersects with the center line of the steady flow tube body 1, and the reflector frame 2 is connected to the reflector cavity through the reflector bracket 5 The pipe body 4 is fixedly connected, and a reflector 3 is installed on one side of the reflector frame 2, and the two reflectors 3 are opposite, and it is characterized in that the other side of the reflector frame 2 is provided with a bullet-shaped fluid 6, and the bullet-shaped stabilizer The bottom end of the fluid 6 is an inclined plane, and the bullet-shaped stabilizing fluid 6 is fixedl...

Embodiment 3

[0027] Embodiment 3: as attached figure 1 , 2, 3, 4, and 5, a bullet-type current stabilizer is provided with a steady flow pipe body 1, a reflector frame 2, a reflector 3 and a reflection chamber body 4, and the two ends of the steady flow pipe body 1 are respectively provided with There is a reflective cavity body 4, the reflective cavity body 4 is provided with a reflector frame 2, the center line of the reflector frame 2 intersects the center line of the steady flow tube body 1, and the reflector frame 2 passes through the reflector bracket 5 is fixedly connected with the reflecting cavity tube body 4, and a reflecting mirror 3 is installed on one side of the reflecting mirror frame 2, and the two reflecting mirrors 3 are opposite, and it is characterized in that the other side of the reflecting mirror frame 2 is provided with a bullet-shaped steady fluid 6, so The bottom end of the bullet-shaped stabilizing fluid 6 is an inclined plane, and the bullet-shaped stabilizing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com