Brake support hole location degree measuring instrument

A technology of hole position degree and brake bracket, which is applied in the field of measuring instruments for detecting the position degree of brake bracket holes, can solve the problems of complex operation and affecting the efficiency of mass production, and achieve the effect of simple operation and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

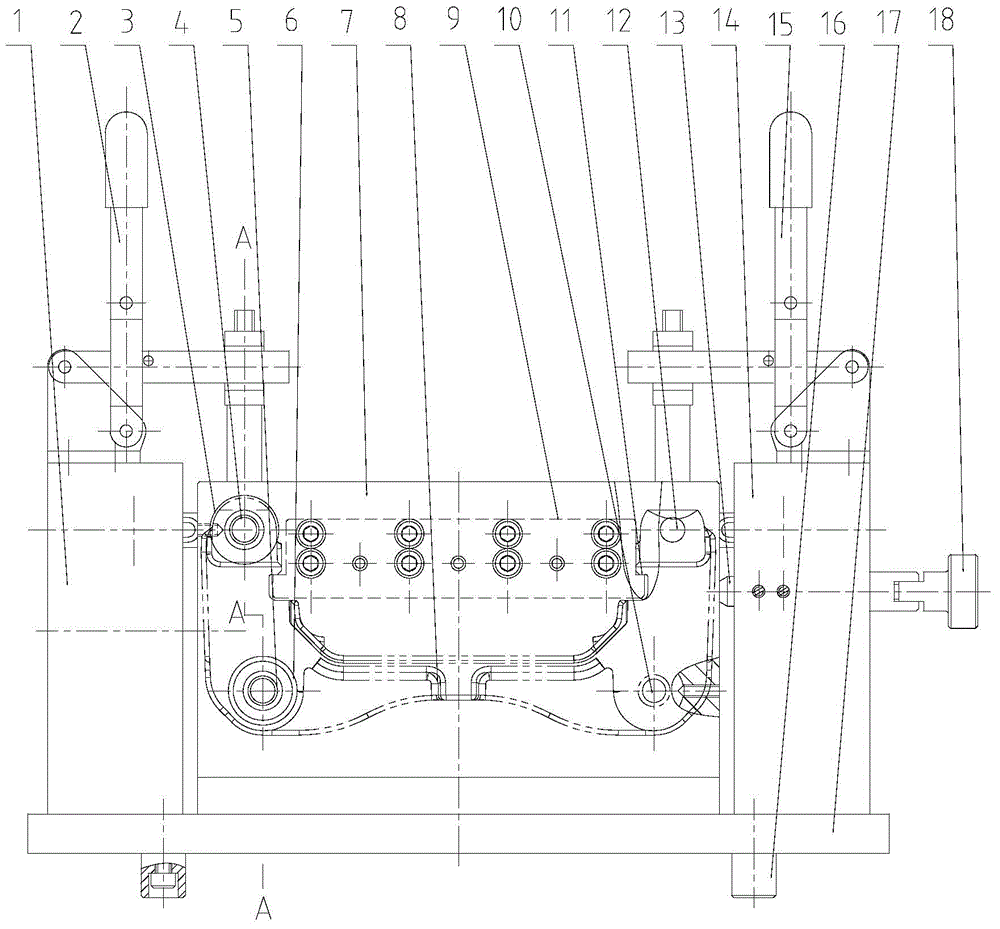

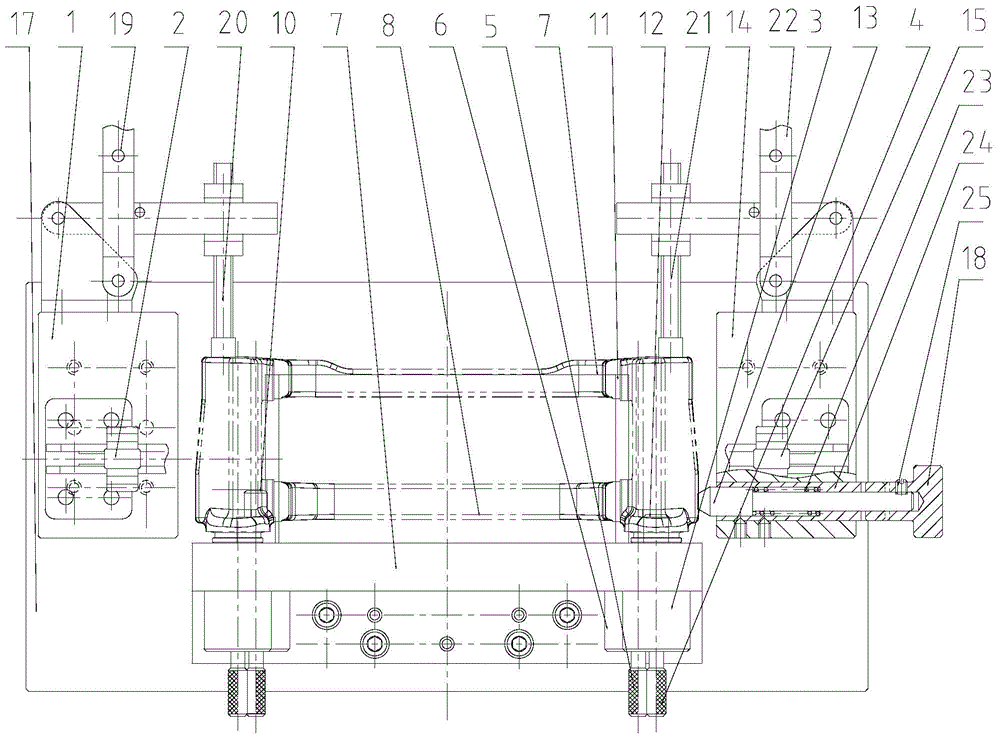

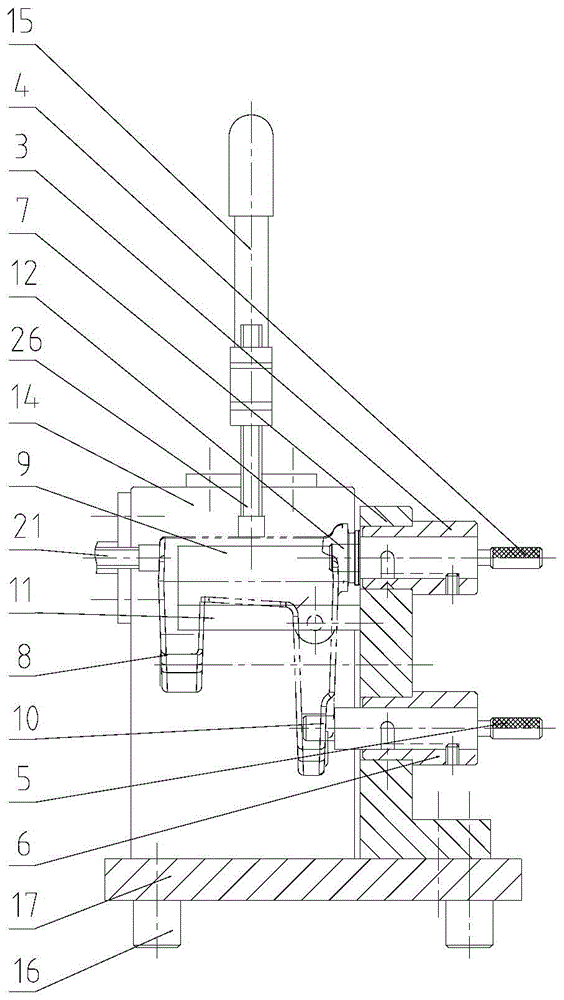

[0022] see Figure 1-4 , the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] This embodiment is composed of base plate 17, vertical plate 7, left clip assembly, right clip assembly, positioning block 9, left measuring assembly, right measuring assembly and clamping assembly.

[0024] Base plate 17 is a rectangular plate (also can be other shapes), and four (also can be three or five or other quantity) supporting feet 16 are installed at its four corners below.

[0025] The section of the vertical plate 7 is "L" shaped, and is installed on the base plate 17 .

[0026] There are positioning steps 11 on both sides of the positioning block 9, forming a "convex" shape, which is installed on the vertical plate 7.

[0027] The left clip assembly and the right clip assembly have the same structure, and are symmetrically installed on the base plate 17 and both sides of the positioning block 9; taking the left clip assembly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com