Support member

A technology of supporting components and supporting rods, which is applied in the direction of supporting machines, machine tables/brackets, shock absorbers, etc., can solve the problems of glass substrate support, etc., and achieve the effect of length attenuation compensation and flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be practiced.

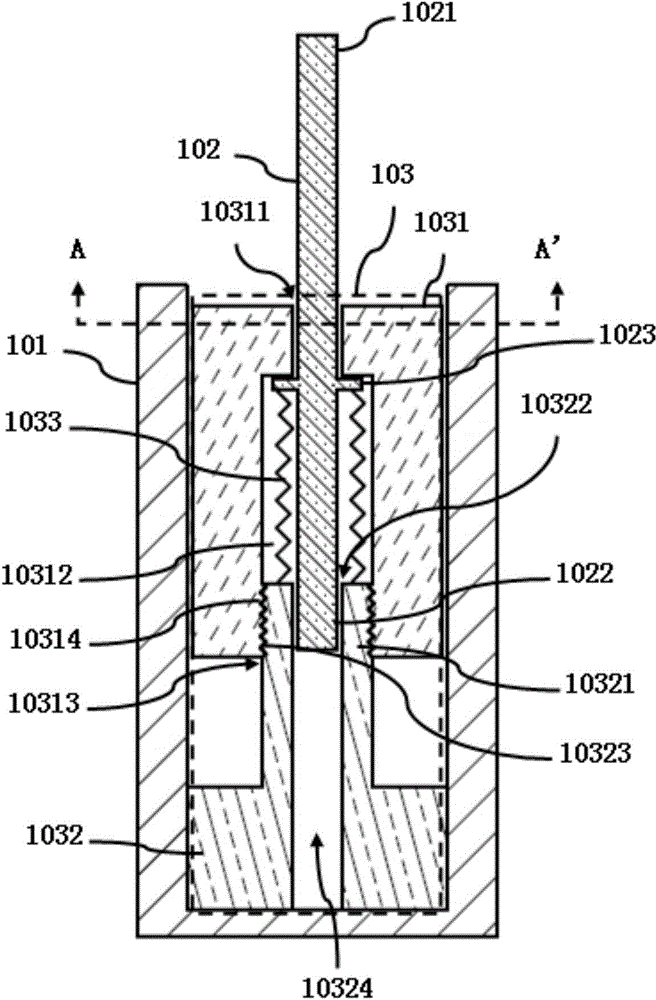

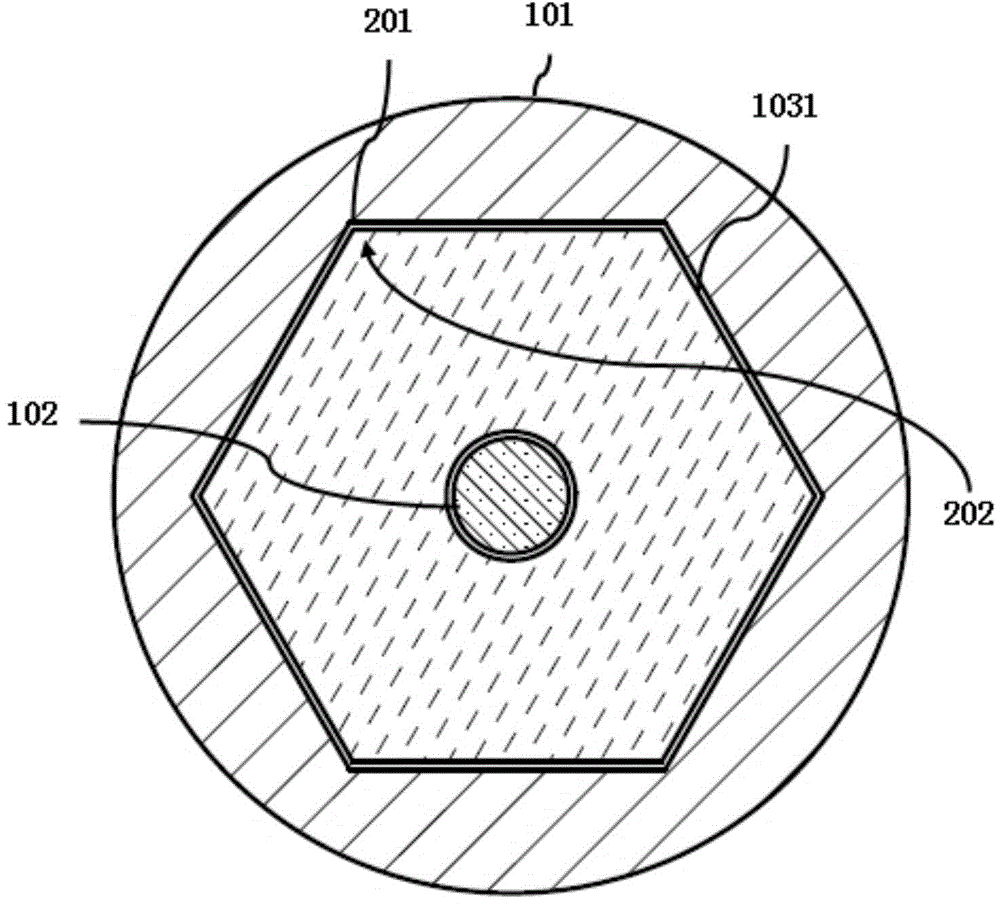

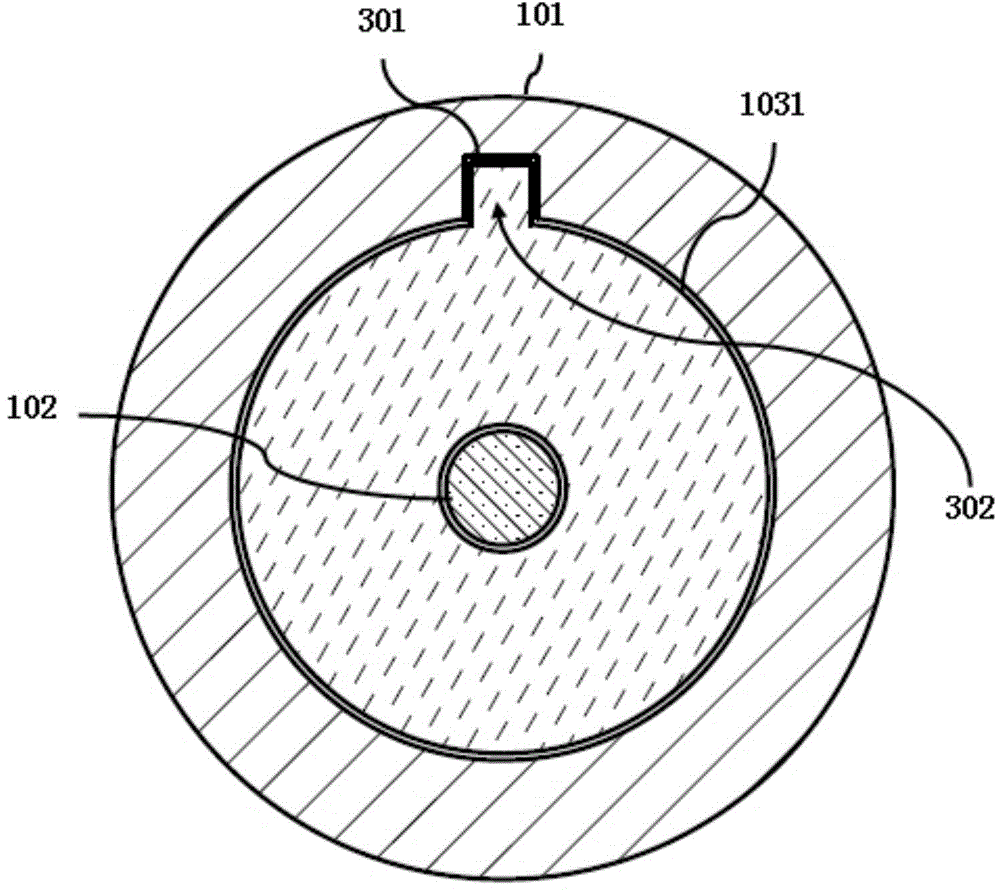

[0027] refer to figure 1 , figure 2 and image 3 , figure 1 is a schematic diagram of the first embodiment of the support member of the present invention, figure 2 for figure 1 The schematic diagram of the first embodiment of the A-A' section in the middle, image 3 for figure 1 Schematic diagram of the second embodiment of the section A-A' in the middle.

[0028] The supporting member in this embodiment includes a housing 101 , a supporting rod 102 and an adjusting member 103 . Wherein, the casing 101 may be configured in a tubular shape. The support rod 102 has a first end 1021 and a second end 1022 , the support rod 102 has an engaging portion 1023 , and the engaging portion 1023 is located between the first end 1021 and the second end 1022 . The locking part 1023 can be a buckle (for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com