Novel fixture

A tooling and a new type of technology, applied in the field of mechanical clamping, can solve the problems of easy error in visual height, high production cost, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

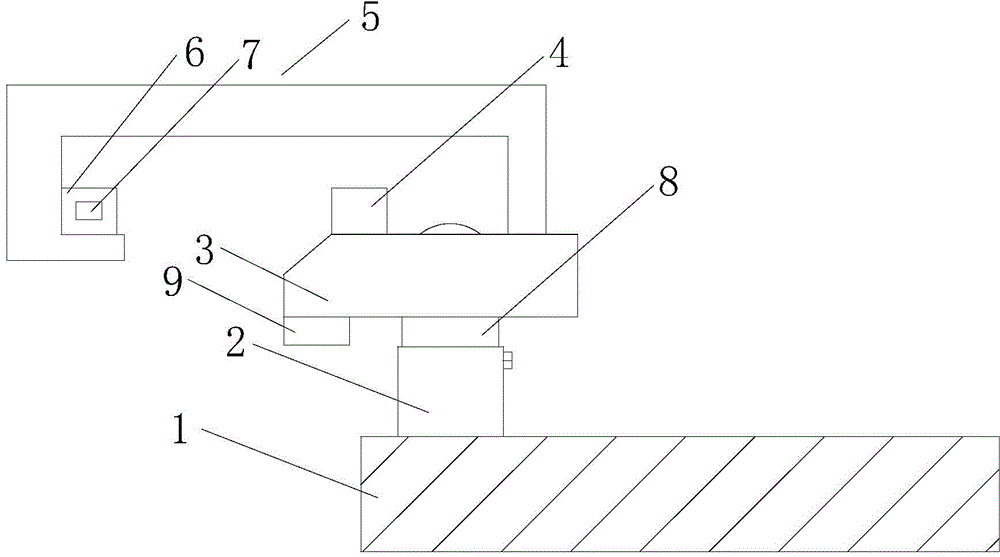

Image

Examples

Embodiment 2

[0015] The bracket and the pressure plate bracket are welded. Since the bracket and the pressing plate are welded, different materials can be used for the bracket and the pressing plate, thereby saving production cost.

Embodiment 3

[0017] The outside of the pressure plate is coated with a wear-resistant coating. Since the pressure plate needs to be in constant contact with the workpiece, the contact end of the pressure plate is subject to more friction than the bracket and is easy to wear; in order to prolong the service life of the pressure plate, a wear-resistant coating is applied; preferably, the wear-resistant coating can be ceramic or graphite.

Embodiment 4

[0019] A cylindrical flange 9 is provided on the bottom surface of the end of the pressing plate protruding from the base. Due to the cylindrical flange, the contact area between the pressure plate and the workpiece is larger, so that the compression effect of the pressure plate is better, and the wear on the surface of the workpiece is avoided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com