Beach cleaning trolley

A cleaning vehicle and cleaning technology, which is applied in the field of beach cleaning vehicles, can solve problems such as damage to garbage conveying devices and oil cylinders, affecting the normal operation of cleaning vehicles, and inability to remove beach garbage, so as to reduce processing accuracy, improve cleaning efficiency, and increase effective The effect of working length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Such as figure 1 As shown, the beach cleaning vehicle disclosed in the present invention includes a crawler chassis 3, a vehicle frame 2, a cleaning roller device 6, a garbage conveying device 4 and a garbage bin assembly 1. The vehicle frame 2 is fixedly connected to the crawler chassis 3, and the cleaning roller device 6 is horizontally connected to the front end of the garbage conveying device 4. Above, the dustbin assembly 1 is hinged to the rear end of the vehicle frame 2 to receive the garbage collected by the garbage conveying device 4 . The vehicle frame 2 is also connected with a rubbish grabbing device 5, which is used to remove elongated rubbish and bulky rubbish that the cleaning roller device 6 cannot collect.

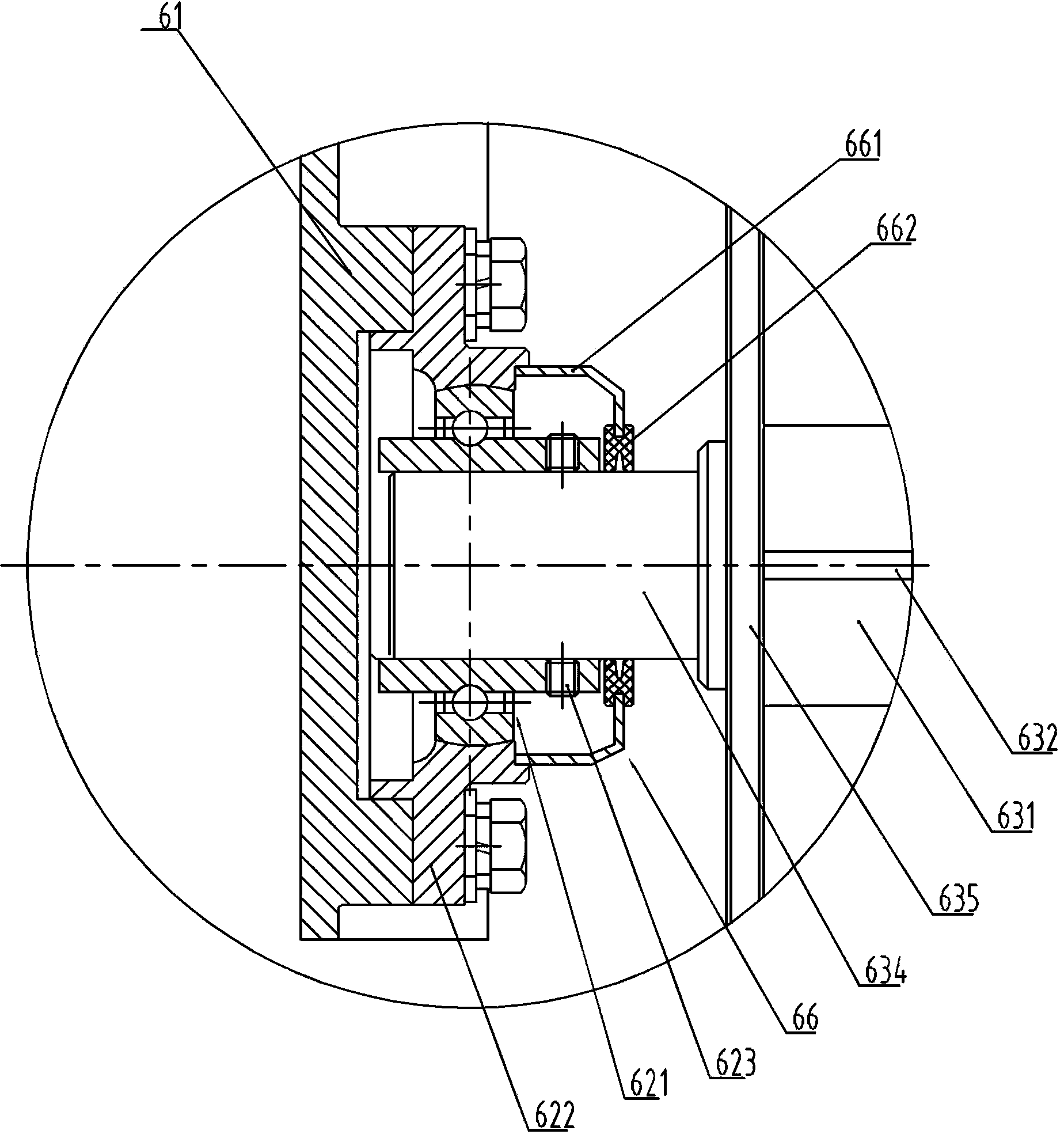

[0044] Such as Figure 2 to Figure 7 As shown, the cleaning roller device 6 includes a cleaning roller fixing frame 61 , a cleaning roller 63 , an outer spherical bearing with seat 62 , a flexible coupling 64 , a hydraulic motor 65 , and a dustpro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com