Bridge Deck Support Dropping Beam Method and Special Support Device for Medium and Small Bridges

A technology of supporting device and falling beam, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as difficulty in supporting bridge falling, and achieve the effect of reducing construction difficulty, improving economic benefits, and reducing construction safety risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

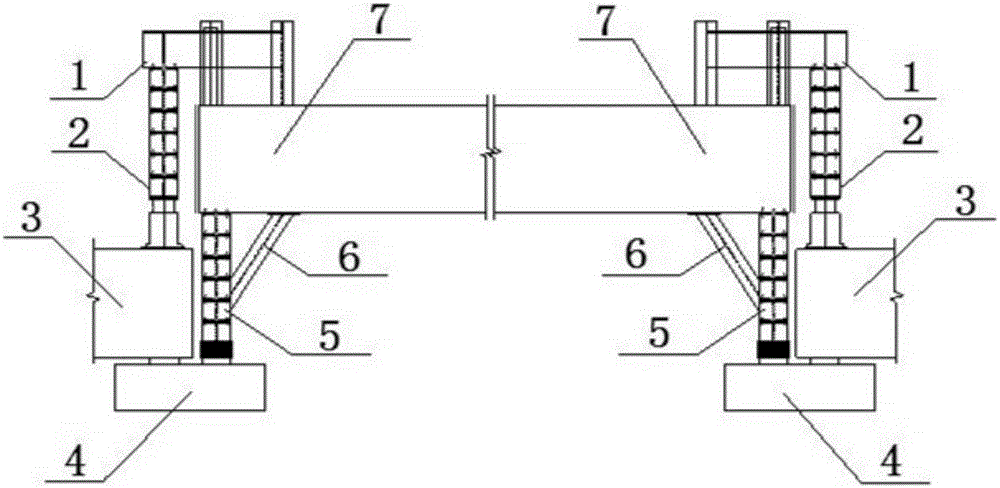

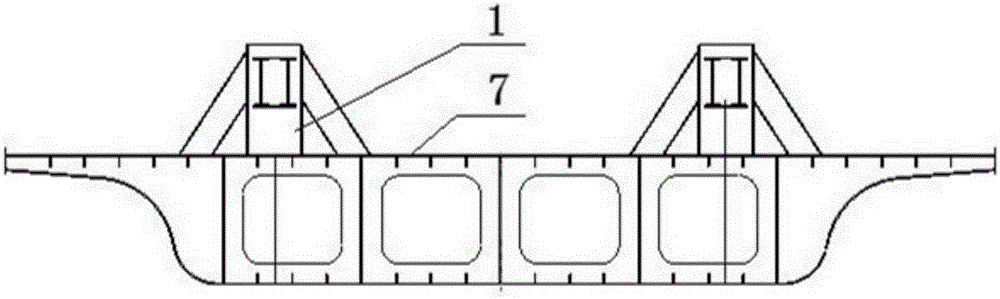

[0017] After the steel beam is pushed in place, remove the pushing mechanical structure; install auxiliary support piers, jacking support piers and oil tops. Weld 4 sets of steel support frames with a cantilevered structure at one end on the top of the steel beam. The support frame should be designed according to the weight of the steel beam, so that it will not deform when the jack is lifted up, and the weld seam will not crack. One set of jacks and steel pads are installed at each cantilevered end to form a jacking support pier. A set of auxiliary support piers is set at each pad stone position, and a steel plate stack with a thickness of 120mm is set at the contact between the pier and the pad stone. Each steel plate has a thickness of 12mm and a size of 400mm×400mm. When the height of the jacking support pier and the auxiliary support pier is relatively large, it is necessary to weld oblique H-shaped steel supports to improve the stability of the support pier. The height ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com