A polypropylene kettle alloy containing nanoparticles that can be used for 3D printing and its preparation method and application

A technology of nano-particles and alloys in kettles, applied in metal processing equipment, 3D object support structures, manufacturing tools, etc., can solve problems such as difficult, polypropylene degradation, and preparation of micron-scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0084] 1. Preparation of Nanoparticle-supported Catalysts

[0085] The preparation steps of nanoparticle carrier type Ziegler-Natta catalyst:

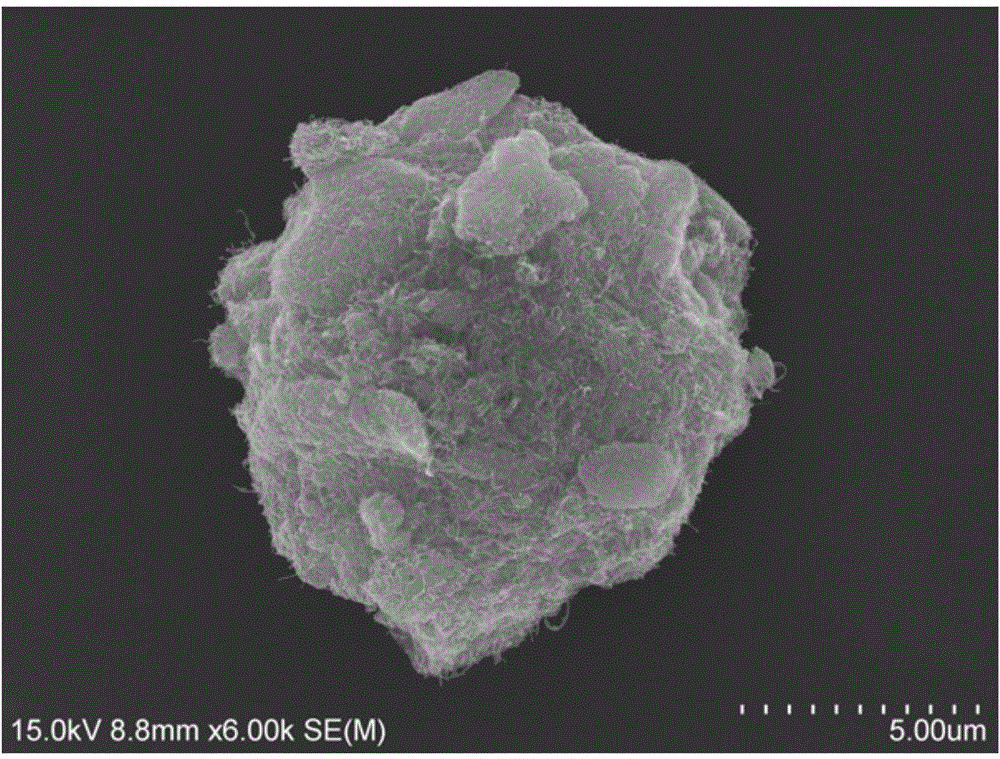

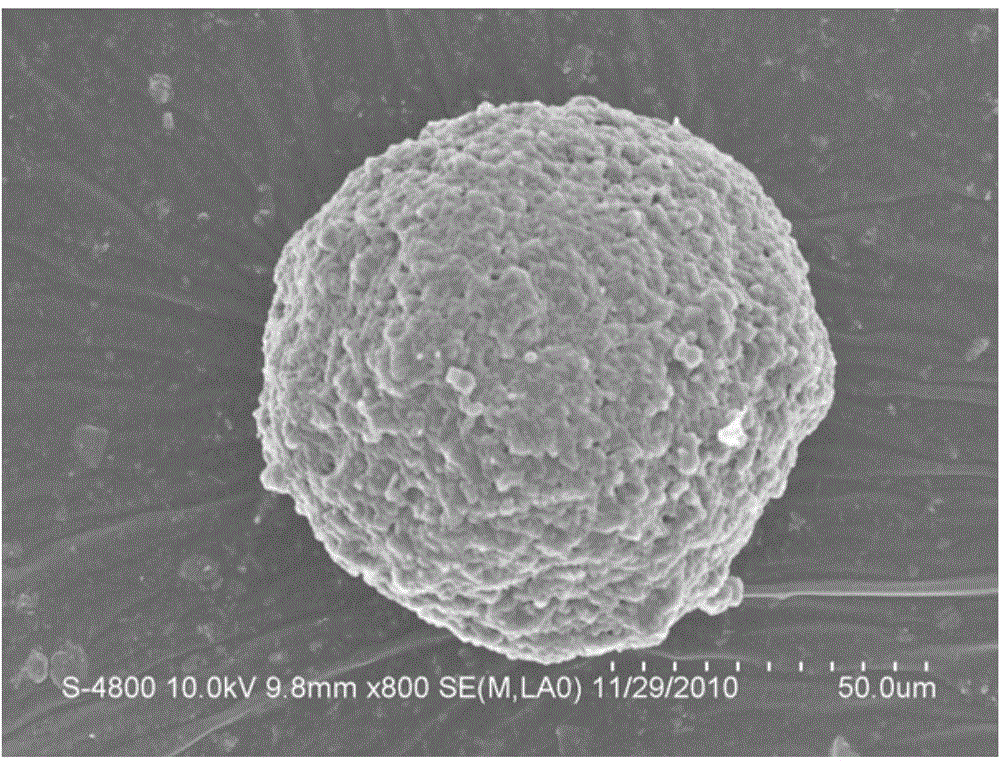

[0086] The nanoparticle carrier type Ziegler-Natta catalyst used in the present invention is nanoparticle / internal electron donor / MgCl 2 / TiCl 4 The carrier type catalyst is characterized in that a diether or diester compound is used as an internal electron donor, and the diameter of the catalyst particle is 0.1-30 μm. Prepare as follows:

[0087] Weigh 10g anhydrous MgCl 2 Add to a two-neck flask filled with argon gas and magnetic stirring, then add 47.8mL of isooctyl alcohol and 60mL of decane, slowly heat to 130°C while stirring, react at 130°C for 1h until the solution is clear, then cool to 60-80°C °C, add 2.10 g of phthalic anhydride, add 2 g of nanoparticles, and stir overnight until the solution is clear. Under an argon atmosphere, the TiCl 4Add 250 mL into a well-dried Schlenk reactor, cool down to -20°C, slowly add the ...

Embodiment 1

[0105] Under normal temperature and pressure, 0.05MPa of H was introduced into the 2L polymerization reactor filled with propylene gas. 2 , add 300g of liquid propylene, 4ml of triethylaluminum solution (heptane solution with a concentration of 1.8mol / L) and 200mg of multi-walled carbon nanotubes / BMMF / MgCl 2 / TiCl 4 Carrier-type catalyst, the reactor is raised to 70 ° C for polymerization, after 60 minutes of reaction, the temperature of the polymerization reactor is lowered to room temperature, and the residual gas in the polymerization reactor is vented, and then the mixed gas of ethylene and propylene (molar ratio 1 : 3), feed hydrogen 0.05g, pressure is 0.5MPa, be heated up to 80 ℃, react 120min, take out the polymer that polymerization reaction obtains, vacuum-dry 6h, obtain the alloy powder in the polypropylene kettle of 200g gray carbon nanotubes .

[0106] In the obtained polypropylene kettle alloy containing carbon nanotubes, the content of carbon nanotubes is 0.1%,...

Embodiment 2

[0108] Feed 0.2MPa of H into the 2L polymerization reactor filled with propylene gas under normal temperature and pressure. 2 , add 300g of liquid propylene, 5ml of triethylaluminum solution (heptane solution with a concentration of 1.8mol / L) and 200mg of montmorillonite BMMF / MgCl 2 / TiCl 4 Supported catalyst, the reactor is raised to 70 ° C for polymerization, after 30 minutes of reaction, the temperature of the polymerization reactor is lowered to room temperature, and the residual gas in the polymerization reactor is vented, and then the mixed gas of ethylene and 1-butene ( The molar ratio is 1:2), 0.05g of hydrogen gas is introduced, the pressure is 0.6MPa, the temperature is raised to 80°C, and the reaction is carried out for 30min. alloy powder.

[0109] In the obtained polypropylene kettle alloy containing montmorillonite, the content of montmorillonite is 0.12%, and the molecular weight of homopolypropylene is 2×10 5 g / mol, the molecular weight distribution is 8.0, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com