Heat-conductive high-molecular-weight nylon powder for 3D printing and preparation method thereof

A high-molecular-weight, nylon powder technology, applied in the field of high-molecular-weight nylon powder and its preparation, can solve the problems of poor dimensional stability and heat resistance, and improve mechanical properties, thermal stability, and interfacial interaction force Strong, uniform particle size distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

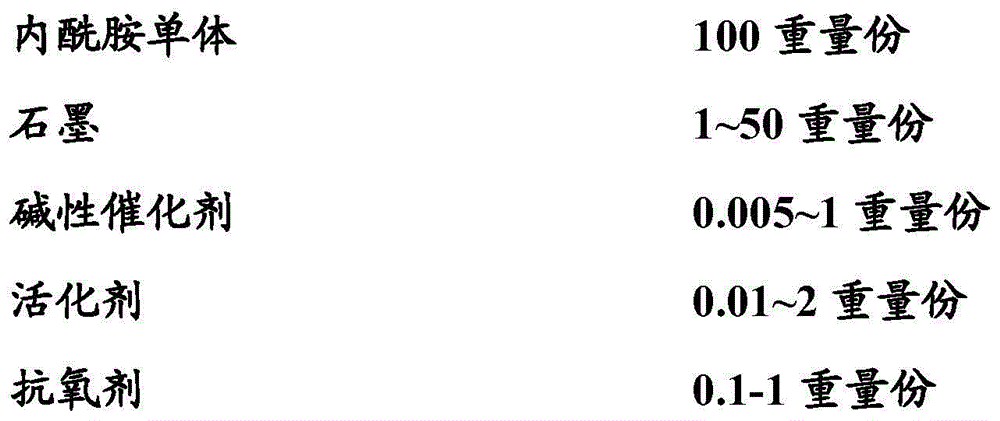

Method used

Image

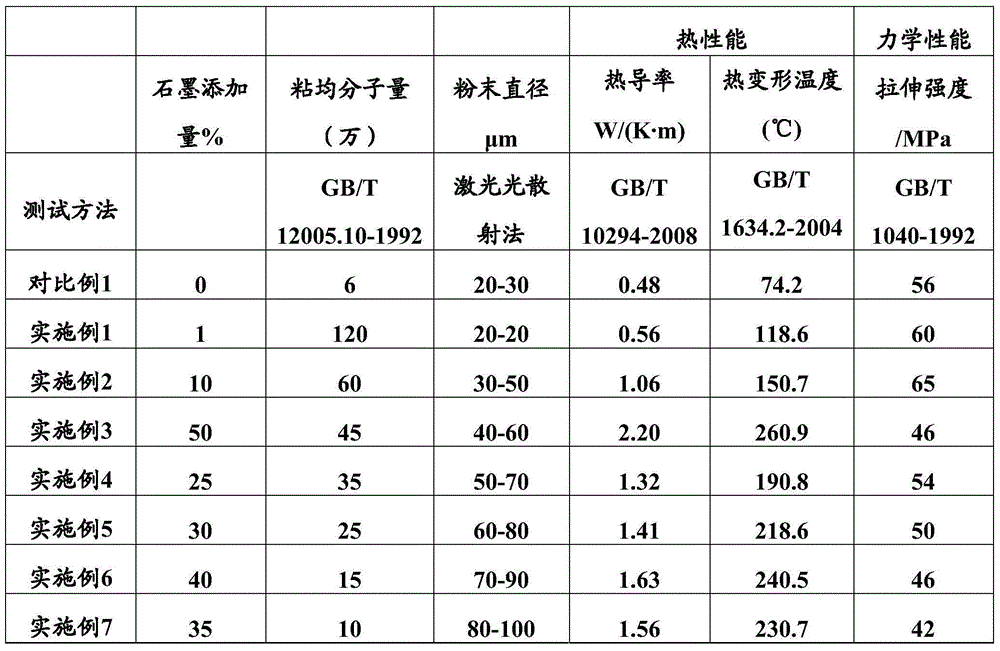

Examples

Embodiment 1

[0062] Based on the weight part of caprolactam monomer, add 100 parts by weight of caprolactam monomer and 1 part by weight of flake graphite with a particle size of 5 microns into the container, and vacuumize at a temperature of 90 ° C. Dehydration, when the pressure of the system shown on the vacuum gauge is <400Pa, remove the vacuum, add 0.005 parts by weight of sodium hydroxide and 0.1 parts by weight of antioxidant 1010, continue vacuuming, and raise the temperature to 130 ° C, when the vacuum gauge shows When the pressure of the system is less than 400Pa, keep it warm for 10 minutes, add 0.01 parts by weight of p-phenylene 2,4-diisocyanate, stir until the mixture is uniform, and pour it into a preheated to 160°C with a particle size of 1 micron. In a sand container, keep warm and stir vigorously for 10 minutes, then cool down naturally to 25°C, and then use a suction air separator to separate and obtain heat-conducting nylon composite powder with a viscosity-average molec...

Embodiment 2

[0068] Based on the weight part of caprolactam monomer, add 100 parts by weight of caprolactam monomer and 10 parts by weight of expanded graphite with a particle size of 0.5 microns into the container, and vacuumize at a temperature of 100 ° C. Dehydration, when the pressure of the system shown by the vacuum gauge is <400Pa, remove the vacuum, add 0.007 parts by weight of potassium hydroxide and 0.5 parts by weight of antioxidant 1096, continue vacuuming, and raise the temperature to 135 ° C, when the pressure shown by the vacuum gauge When the pressure of the system is less than 400Pa, heat preservation reaction for 10 minutes, add 0.15 parts by weight of Lechner glue, stir until evenly mixed, pour iron, nickel, In the container of the cobalt magnetic material powder, heat preservation and vigorous stirring for 10 minutes, then naturally cool down to 25°C, heat preservation and vigorous stirring for 10 minutes, naturally cool to 25°C, and then use a magnetic separation separa...

Embodiment 3

[0070] Based on the weight part of dedecalactam monomer, 100 parts by weight of dedecalactam monomer and 50 parts by weight of aphanitic graphite with a particle size of 10 microns are added to the container, and the vacuum is drawn at a temperature of 120 ° C. , carry out dehydration in a vacuum state, when the pressure of the system shown by the vacuum gauge is <400Pa, remove the vacuum, add 1 weight part of magnesium hydroxide and 1 weight part of antioxidant 168, continue vacuuming, and raise the temperature to 140°C , when the pressure of the system shown by the vacuum gauge is <400Pa, heat the reaction for 20 minutes, add 2 parts by weight of hexamethylene diisocyanate, stir until the mixture is uniform, and pour it into a container with a particle size of 20 microns that has been preheated to 180°C In the machine-made sand container, keep warm and stir vigorously for 20 minutes, then naturally cool down to 25°C, and then use a circulating wind separator to obtain thermal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com