A glass fiber random structure sandwich material and its preparation method

A glass fiber, sandwich material technology, applied in chemical instruments and methods, glass/slag layered products, lamination auxiliary operations, etc., can solve problems such as low compression and shear performance, rapid collapse failure, high maintenance costs, etc. , to achieve the effect of simple and easy preparation process, realizing spatial structure and maintaining structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

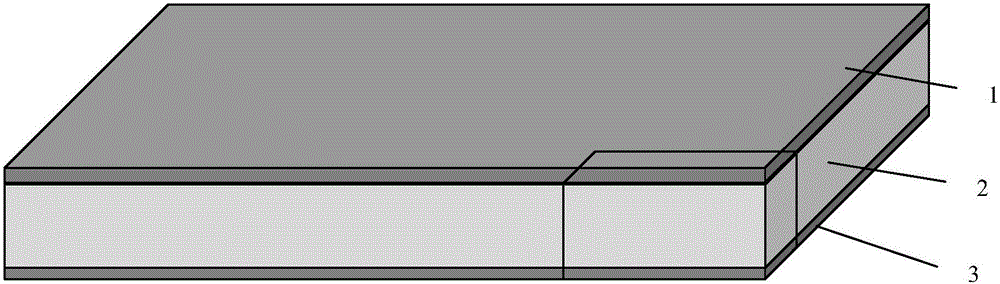

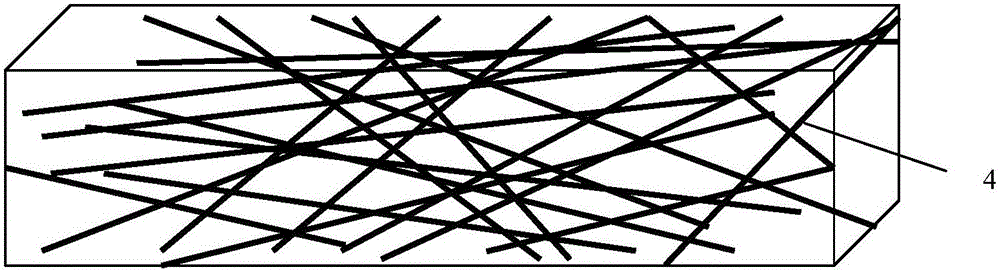

[0028] The structure diagram of glass fiber random structure sandwich material is as follows figure 1 As shown, the forming mold is fully cleaned, dried and coated with a release agent, and the prefabricated upper panel (1) and lower panel (3) are respectively laid on the upper and lower molds; 300tex glass fiber bundles are manually dipped Fully impregnated with unsaturated polyester resin glue and wound on the frame-shaped steel frame, pre-cured at 20°C for 2 hours, post-cured at 80°C for 1 hour, after curing and molding, the cured glass fiber bundles were removed from the frame-shaped steel frame, and finally Cut the cured glass fiber bundles into 30mm chopped glass fiber bundles by a cutting machine; mix the cut chopped glass fiber bundles with an unsaturated polyester resin molding glue system that accounts for 10% of the mass fraction of the chopped glass fiber bundles , stir with a four-fork stirrer for 2min, the preferred 30r / min of the rotating speed makes the chopped...

Embodiment 2

[0030] Fully clean the forming mold, apply a release agent after drying, and lay the prefabricated upper panel (1) and lower panel (3) on the upper and lower molds respectively; fully impregnate 600tex glass fiber bundles through the immersion dipping process The unsaturated polyester resin glue is wound on the frame-shaped steel frame, pre-cured at 30°C for 1 hour, and post-cured at 130°C for 2 hours. After curing, the cured glass fiber bundles are removed from the frame-shaped steel frame, and finally cured The glass fiber bundles are cut into 40mm chopped glass fiber bundles by a cutting machine; the cut chopped glass fiber bundles are mixed with an unsaturated polyester resin molding glue system that accounts for 15% of the chopped glass fiber bundle mass fraction, and The six-pronged stirrer was stirred for 5 minutes, and the rotating speed was preferably 40r / min, so that the chopped glass fiber bundles formed an irregular spatial framework structure; then the chopped glas...

Embodiment 3

[0032]Fully clean the forming mold, apply a mold release agent after drying, and spread the prefabricated upper panel (1) and lower panel (3) on the upper and lower molds respectively; use 900tex glass fiber bundles through a vertical dipping process to fully Impregnate the unsaturated polyester resin glue and wrap it on the frame-shaped steel frame, pre-cure at 30°C for 1 hour, and post-cure at 80°C for 1 hour. After curing and molding, remove the cured glass fiber bundle from the frame-shaped steel frame, and finally put The cured glass fiber bundles are cut into 50mm chopped glass fiber bundles by a cutting machine; the cut chopped glass fiber bundles are mixed with an unsaturated polyester resin molding glue system that accounts for 20% of the chopped glass fiber bundle mass fraction, Stir with an octagonal stirrer for 10min, and the preferred 30r / min of the rotating speed makes the chopped glass fiber bundles form an irregular spatial framework structure; then the chopped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com