Seal cooling device for bag loading machine

A cooling device and sealing technology, which is used in packaging, transportation and packaging, container manufacturing machinery, etc., can solve the problems of too tight bonding at the packaging sealing, unable to adjust the air supply strength, affecting the packaging sealing effect, etc., to improve the sealing effect. , convenient control and strong usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

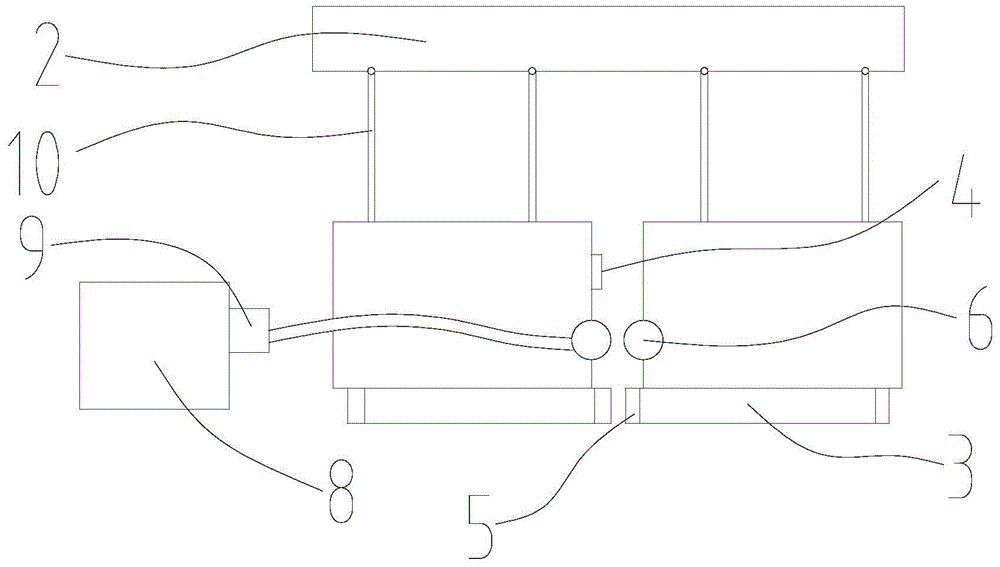

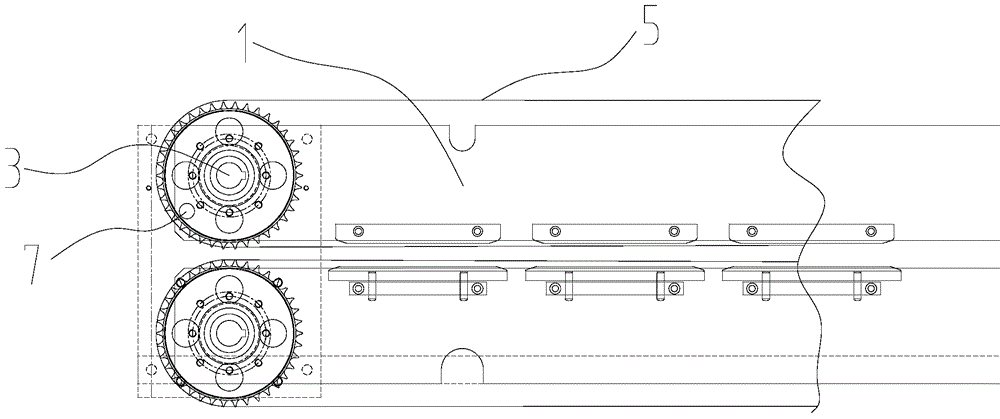

[0014] A sealing and cooling device for a bagging machine, including a frame and an air pump. A pair of transmission track mounting plates are arranged in the frame, and gear turntables are respectively arranged on both ends of the transmission track mounting plate, and the transmission track A temperature sensor is provided on the mounting plate, a transmission crawler is provided between the gear turntables, an air outlet pipe is provided inside the installation board of the transmission track, and a distance sensor is provided at one end of the air outlet pipe. An air pump is connected to the air outlet pipe, and a delay relay is provided at the connection between the air pump and the air outlet pipe.

[0015] The transmission rail mounting plate is fixed in the frame by being provided with an adjustable connecting rod.

[0016] Keep a 5cm ventilation distance between the outlet pipes.

[0017] When the device is working, after the product is sealed and packaged, the dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com