Pipe cutting and grooving machine

A groove machine and cutting groove technology, applied in metal processing and other directions, can solve the problems of uneven cutting surface and cumbersome grooves, and achieve the effect of compact design structure and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

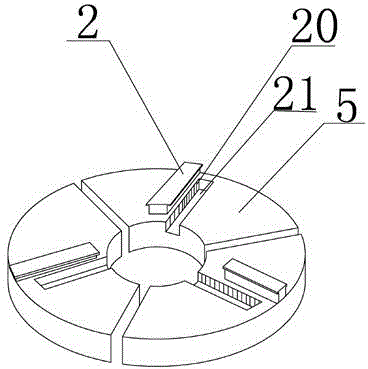

[0039] Embodiment 1: a kind of pipe material cutting, groove machine, see Figure 1 to Figure 8 , including a frame 11, a clamping and rotating mechanism for clamping and rotating the pipe, a cutting groove mechanism for cutting and grooves on the pipe, and a power source correspondingly arranged on the bracket 11;

[0040] Such as figure 2 As shown, the clamping and rotating mechanism includes a fixed cylinder 14 with openings at both ends, a main power wheel 13 arranged correspondingly from left to right, a clamping driving wheel 3, a slave power wheel 4, and three round openings connected in the middle. Holder 5; the middle part of the main power wheel 13 is provided with a circular opening and communicates with one end of the fixed cylinder 14, and a rack 12 is provided on the main power wheel 13, and a Below is provided with the main gear 18 meshed with the main power wheel, and the main gear 18 is correspondingly connected with the power source; as Figure 7 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com