Breeding seed threshing machine used in oilseed rape fields

A thresher and field technology, applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve the problems of large residual amount of grains, long harvest period, mixed grains, etc., and achieve good cleaning effect, no seeds mixed, and productivity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

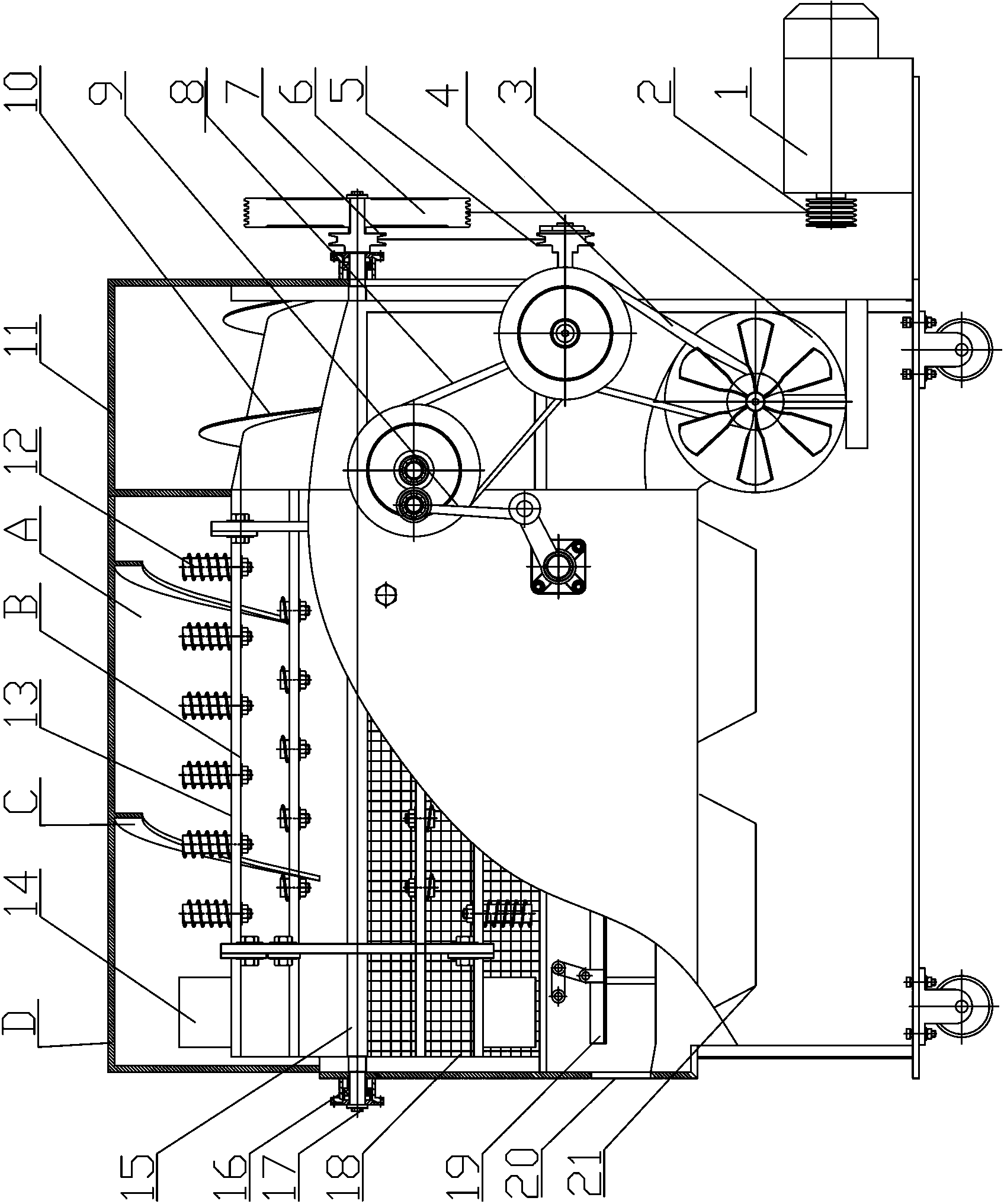

[0044] see Figure 1-Figure 5 , The rape field breeding thresher of the present invention includes a threshing system, a cleaning system and a transmission system installed on the frame D.

[0045]The threshing system includes a threshing chamber A formed by a drum cover 11, a drum shaft 15 installed on the frame D through the drum bearing seat 16 runs through the threshing chamber A, and one end of the drum shaft 15 is provided with a spiral Feed the auger 10 in a shape distribution. A feeding port 25 is arranged on the drum cover 11 corresponding to the feeding auger 10. The feeding port 25 is preferably arranged in the tangential direction of the feeding auger 10, and the protruding part of the feeding port 25 is in an inverted V shape. A shield (not shown) may be provided on the top of the feeding port 25 . Like this, the oilseed rape that is sent into through feeding inlet 25 just can fall into feeding auger 10 places smoothly. The drum shaft 15 located at the output e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com