Heating system

A technology of heating system and automatic equipment, which is applied in the field of heating system, can solve the problem of inability to ensure stable and uniform heating of the baking plate, and achieve the effect of stable heating, avoiding temperature fluctuations and uniform heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

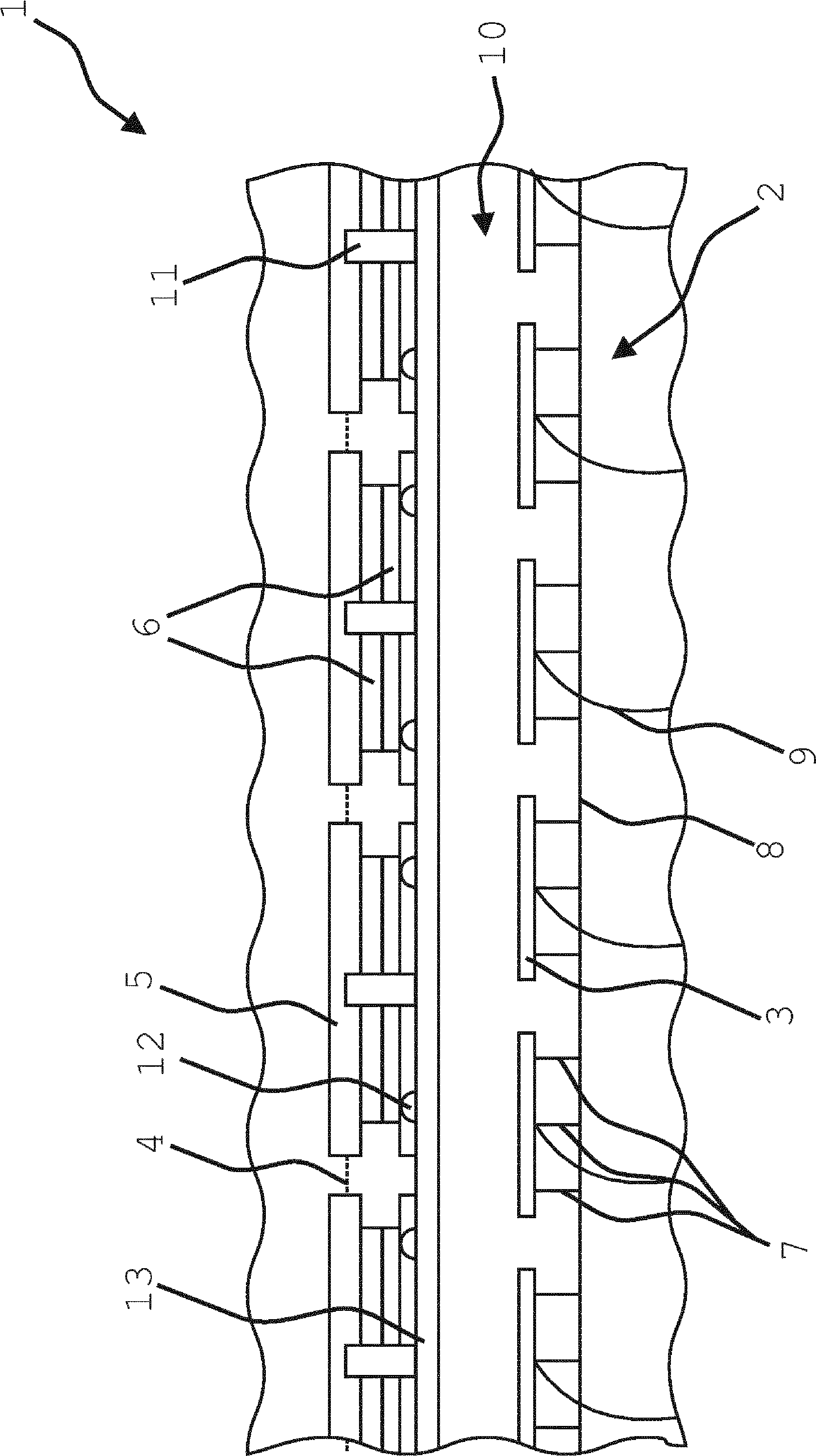

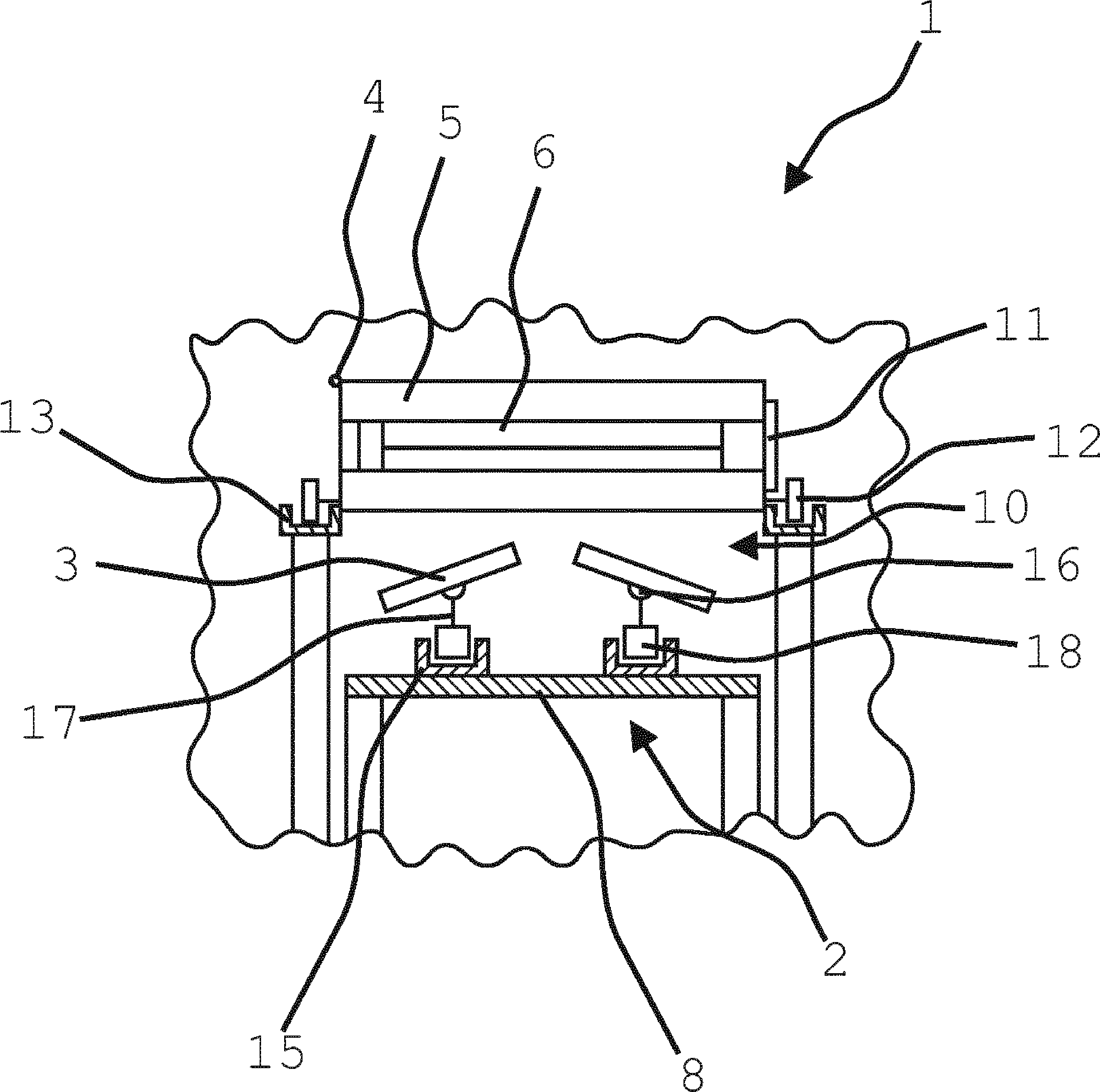

[0033] figure 1 A schematic view of a detail of a bakery automation system 1 is shown. The automatic baking device 1 has a heating system 2 with a plurality of perforated burners 3 for heating a plurality of baking tongs 5 arranged at intervals on a baking tong chain 4, wherein each baking tong 5 each have two baking plates 6 .

[0034] The perforated burner 3 is supported in a swingable manner on a swing device 7 , wherein the swing device 7 is fixed on a carrying frame 8 . The perforated burners 3 are supplied with a gas-air mixture via a gas delivery device 9 and heat the baking chamber 10 to approximately 180° C. The perforated burner 3 reaches temperatures of up to 1400°C. The area power provided by the perforated burner 3 can be steplessly controlled at 150kW / m 2 and 3000kW / m 2 between adjustments. The perforated burner 3 can be pivoted about a horizontal as well as a vertical axis by means of the pivoting device 7 .

[0035] Between the baking plates 6 there is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com