Method for manufacturing LED light source

A technology of LED light source and manufacturing method, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of high cost, complex heat dissipation design, and many process flows, and achieve the effect of reducing material cost and simplifying production process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

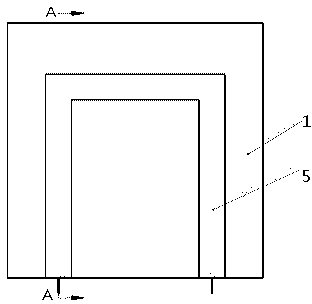

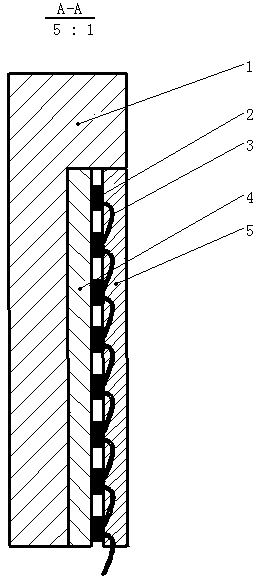

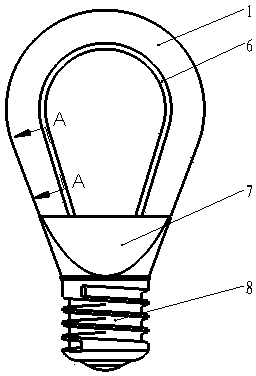

[0017] figure 1 , figure 2 Respectively, a schematic structural view and a cross-sectional view of the LED light source module of the present invention, figure 1 Shown is a schematic diagram after the manufacture is completed, the glass plate 1 on the surface and the fluorescent glue 5 on the surface of the groove of the glass plate 1 can be seen; figure 2 As shown in the A-A direction sectional view, the internal structure of the LED light source module of the present invention can be seen, according to figure 2 The manufacturing method described in the present invention is described as follows:

[0018] (a) casting glass plate 1 with grooves in glass;

[0019] (b) Apply fluorescent glue 4 on the bottom of the groove of the glass plate 1;

[0020] (c) Fix a row of LED chips 2 (usually blue chips) on the fluorescent glue 4 at equal intervals;

[0021] (d) connecting the electrodes of the LED chips 2 in series with gold wires 3;

[0022] (e) Coat another layer of fluor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com