Overhead bare conductor expanding and reinforced insulation structure

A technology for enhancing insulation and wires, applied in the direction of insulated conductors, insulated cables, conductors, etc., to reduce the critical corona distance, reduce the risk of corona discharge, and eliminate the effect of surface corona

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

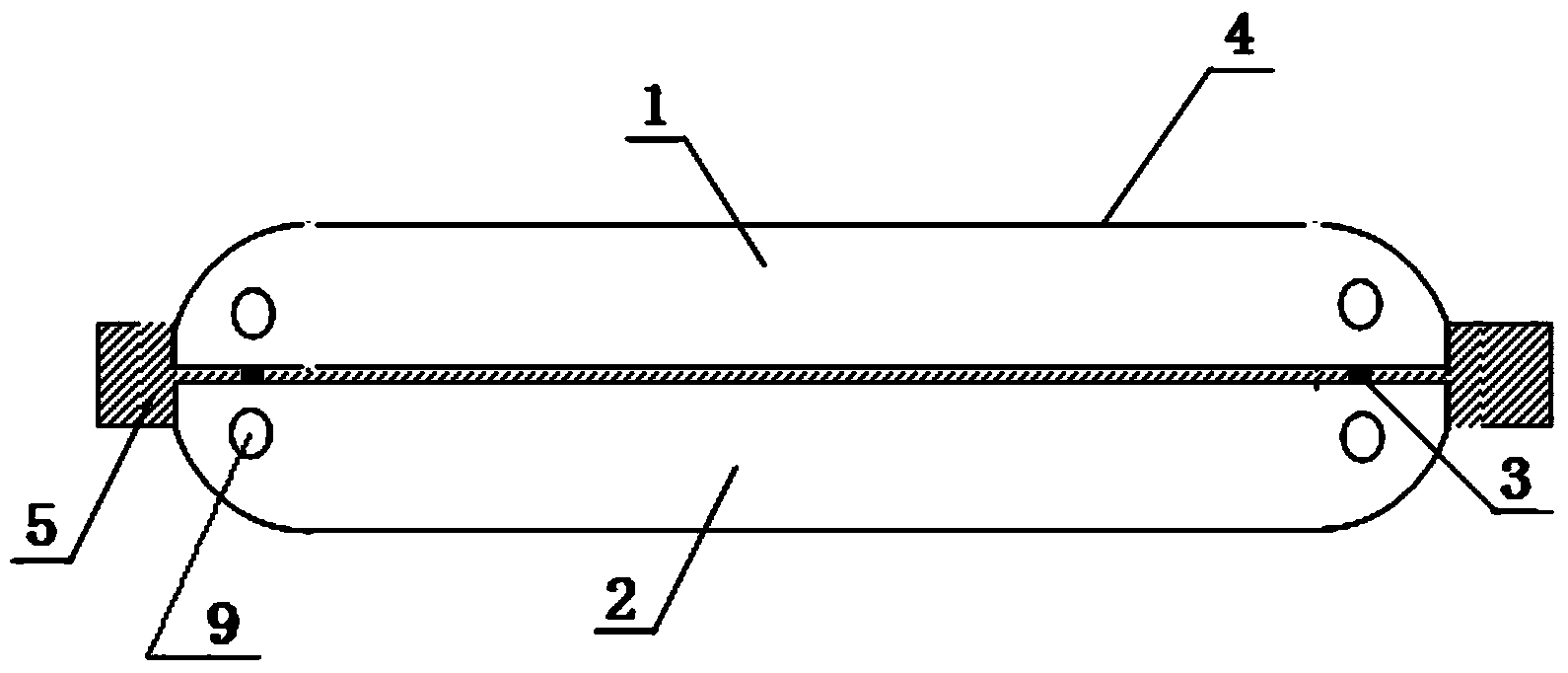

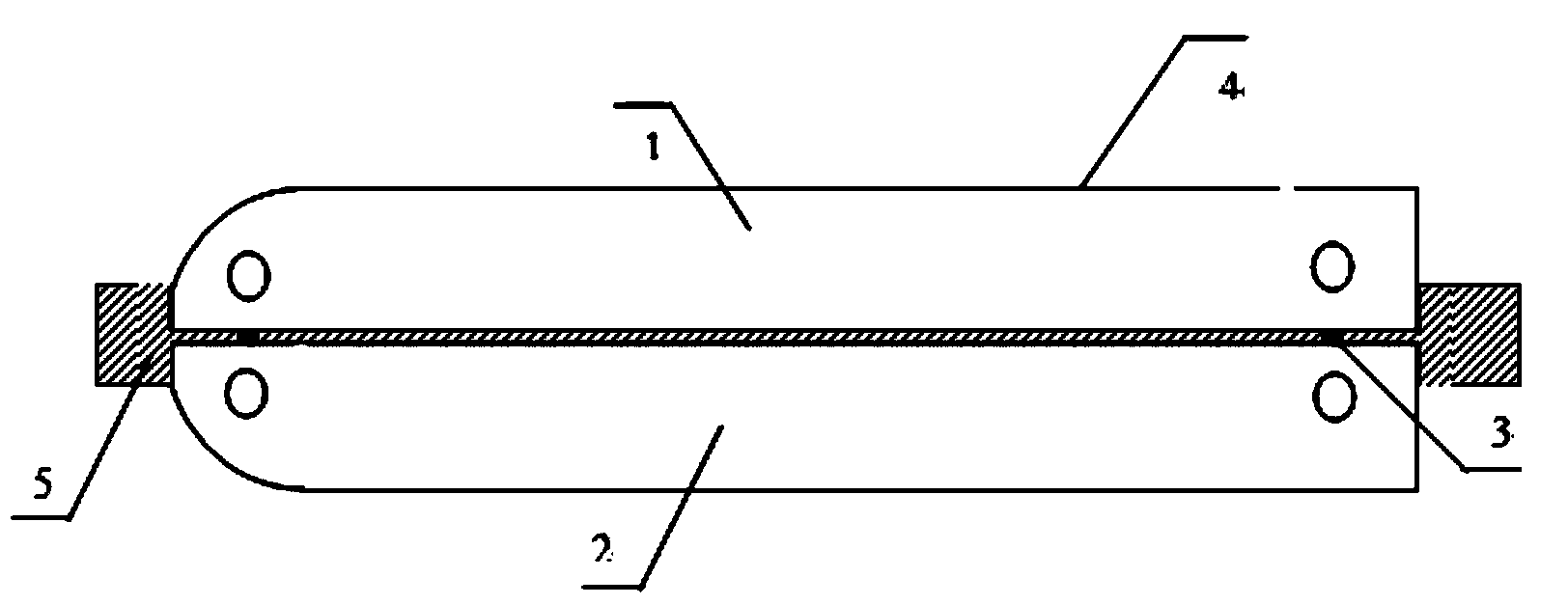

[0031] Such as figure 1 , figure 2 with Image 6 As shown, in this embodiment, a diameter-enlarged reinforced insulation structure for overhead bare wires includes an upper diameter-expanding part 1, a lower diameter-expanding part 2, and an elastic buckle 3 connecting the upper diameter-expanding part 1 and the lower diameter-expanding part 2. The upper diameter expansion part 1 and the lower diameter expansion part 2 have the same structure, and are symmetrically clamped on the upper surface and the lower surface of the overhead bare wire where reinforced insulation is required, and can be installed on the high-voltage bare wire 5 without disassembling the high-voltage bare wire 5. 5 surface to increase its effective radius to achieve the effect of shielding corona, and the reinforced insulation structure of the present invention is connected to the required length as required, which is convenient for construction and can be replaced. The outer surfaces of the upper diame...

Embodiment 2

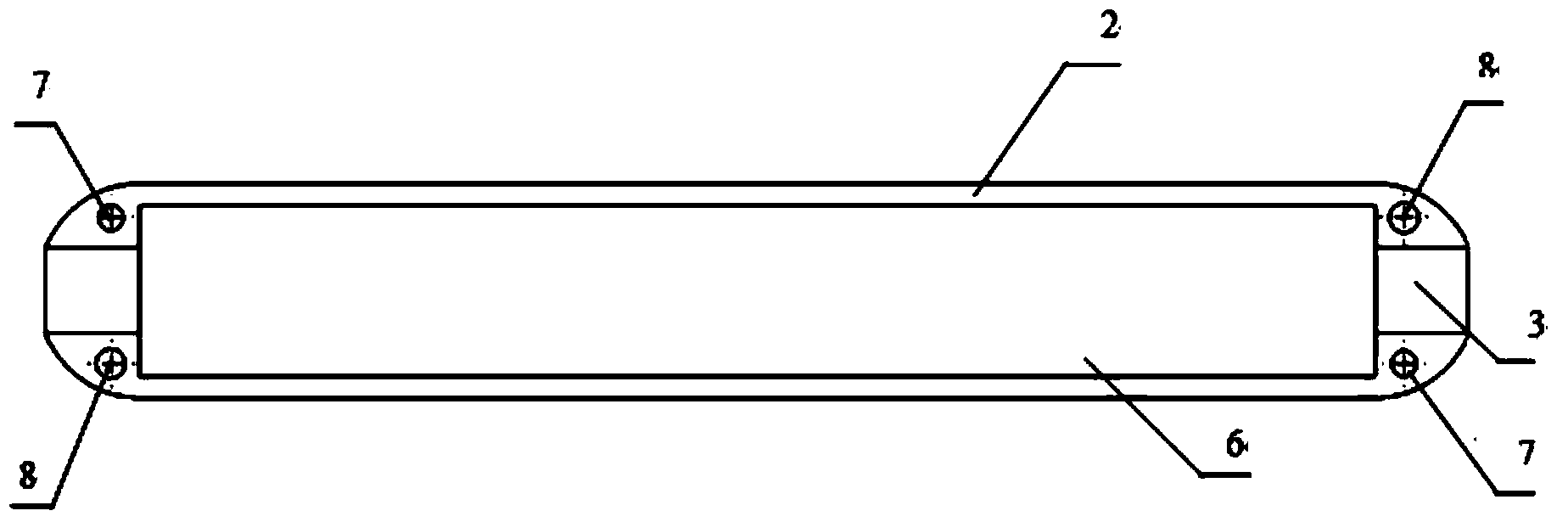

[0033] Such as image 3 with Figure 4 As shown, this embodiment is a kind of reinforced insulation structure for overhead bare wire diameter expansion. structure, or the upper diameter-expanding part 1 and the lower diameter-expanding part 2 are semi-cylindrical. When this structure is used, such as Figure 4 The upper diameter-expanding part 1 and the lower diameter-expanding part 2 shown can be connected in series according to the needs, but the two ends after the series connection must be connected in series as follows: image 3 The upper diameter-expanding part 1 and the lower diameter-expanding part 2 of the shown structure, and one end of the hemispherical structure should be placed at the outermost end.

Embodiment 3

[0035] Such as Figure 5 As shown, the present embodiment is a diameter-enlarged reinforced insulation structure for overhead bare wires. Other structures are the same as those in Embodiment 1, except that the upper diameter-expanding part 1 and the lower diameter-expanding part 2 are hemispherical. When in use, more than one can be connected in series as needed.

[0036] As a preferred embodiment of the present invention, the material of the upper diameter-expanding part 1 and the lower diameter-expanding part 2 is aluminum alloy.

[0037] As a preferred embodiment of the present invention, the elastic buckle 3 is made of copper.

[0038] As a preferred embodiment of the present invention, the wall thickness of the inner hollow structure of the upper diameter-expanding part 1 and the lower diameter-expanding part 2 is less than 5 mm.

[0039] As a preferred embodiment of the present invention, the thickness of the modified epoxy insulating layer 4 is 0.5-1 mm.

[0040]The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com