Manufacturing method for magnetic anti-fake miniature particles

A manufacturing method and miniature technology, which is applied in the directions of marking, instruments, display devices, etc., can solve problems such as limitations in the field of use, and achieve reliable anti-counterfeiting effects, advanced manufacturing technology, and wide application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

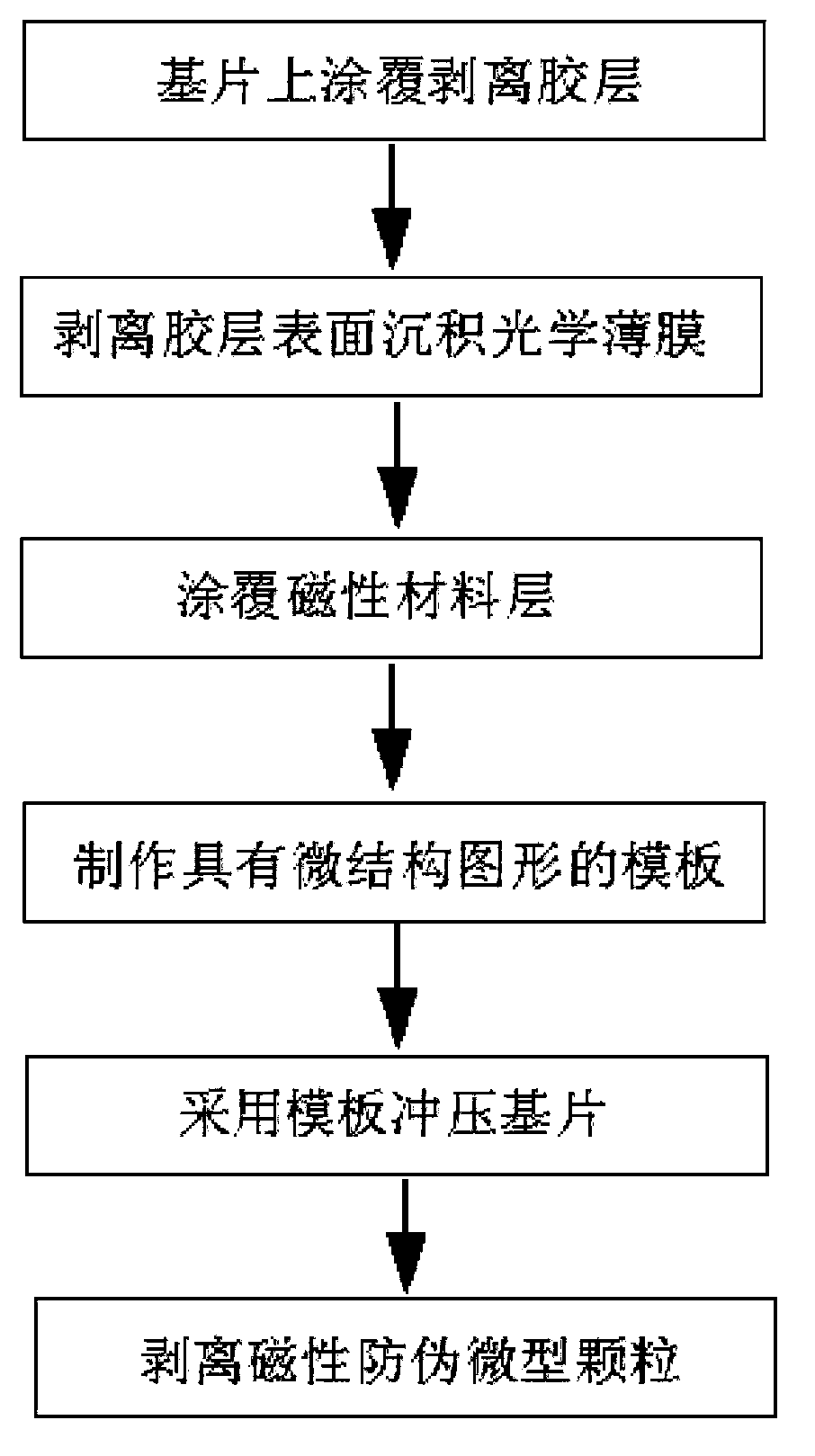

[0035] A kind of manufacturing method of magnetic anti-counterfeit micro-particles, its technological process is as follows figure 1 As shown, the method comprises the following steps: (1) coating a layer of moldable peeling adhesive layer on the substrate with a coating machine, the peeling adhesive layer can be dissolved in organic solvents, or can be melted by heat, so as to remove from the substrate Peeling off on the sheet; (2) depositing an optical film on the surface of the peeling adhesive layer; (3) coating a magnetic material layer on the surface of the optical film; (4) making a template with a microstructure pattern; (5) using a template with a microstructure pattern , punching the substrate, so that the magnetic material layer and the optical film on the substrate are pressed and broken into magnetic anti-counterfeiting micro-particles the same as the microstructure pattern, and the particles are pasted on the substrate by peeling off the adhesive layer; (6) the ma...

Embodiment 2

[0044] A kind of manufacturing method of magnetic anti-counterfeit micro-particles, its technological process is as follows figure 1 As shown, the method comprises the following steps: (1) coating a layer of moldable peeling adhesive layer on the substrate with a coating machine, the peeling adhesive layer can be dissolved in organic solvents, or can be melted by heat, so as to remove from the substrate Peeling off on the sheet; (2) Depositing an optical film on the peeling adhesive layer; (3) Coating a magnetic material layer on the surface of the optical film; (4) Making a template with a microstructure pattern; (5) Using a template with a microstructure pattern , punching the substrate, so that the magnetic material layer and the optical film on the substrate are pressed and broken into magnetic anti-counterfeiting micro-particles the same as the microstructure pattern, and the particles are pasted on the substrate by peeling off the adhesive layer; (6) the magnetic anti-cou...

Embodiment 3

[0052] A kind of manufacturing method of magnetic anti-counterfeit micro-particles, its technological process is as follows figure 1 As shown, the method comprises the following steps: (1) coating a layer of moldable peeling adhesive layer on the substrate with a coating machine, the peeling adhesive layer can be dissolved in organic solvents, or can be melted by heat, so as to remove from the substrate Peeling off on the sheet; (2) depositing an optical film on the surface of the peeling adhesive layer; (3) coating a magnetic material layer on the surface of the optical film; (4) making a template with a microstructure pattern; (5) using a template with a microstructure pattern , punching the substrate, so that the magnetic material layer and the optical film on the substrate are pressed and broken into magnetic anti-counterfeiting micro-particles the same as the microstructure pattern, and the particles are pasted on the substrate by peeling off the adhesive layer; (6) the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com