Spine Biomechanical Simulator

A biomechanical and simulation test technology, applied in the field of spine biomechanical simulation test equipment, can solve the problems of increased rotational movement, low accuracy, inconsistent physiological load conditions, etc., and achieve the effect of reducing rotational movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

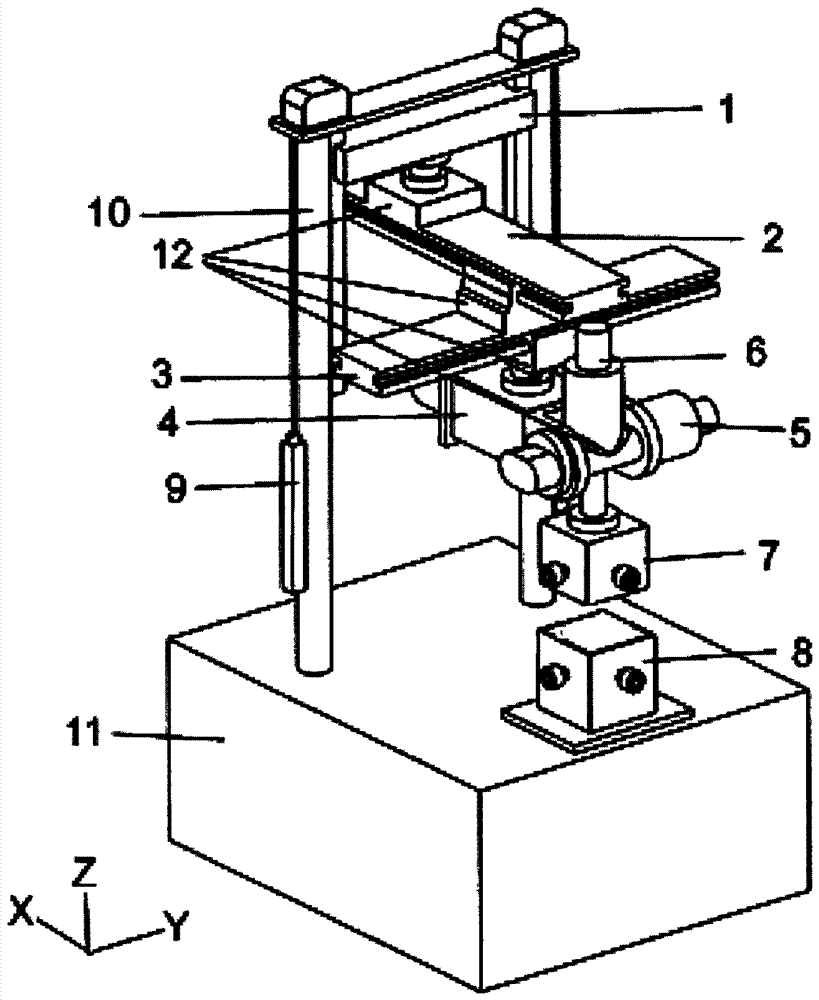

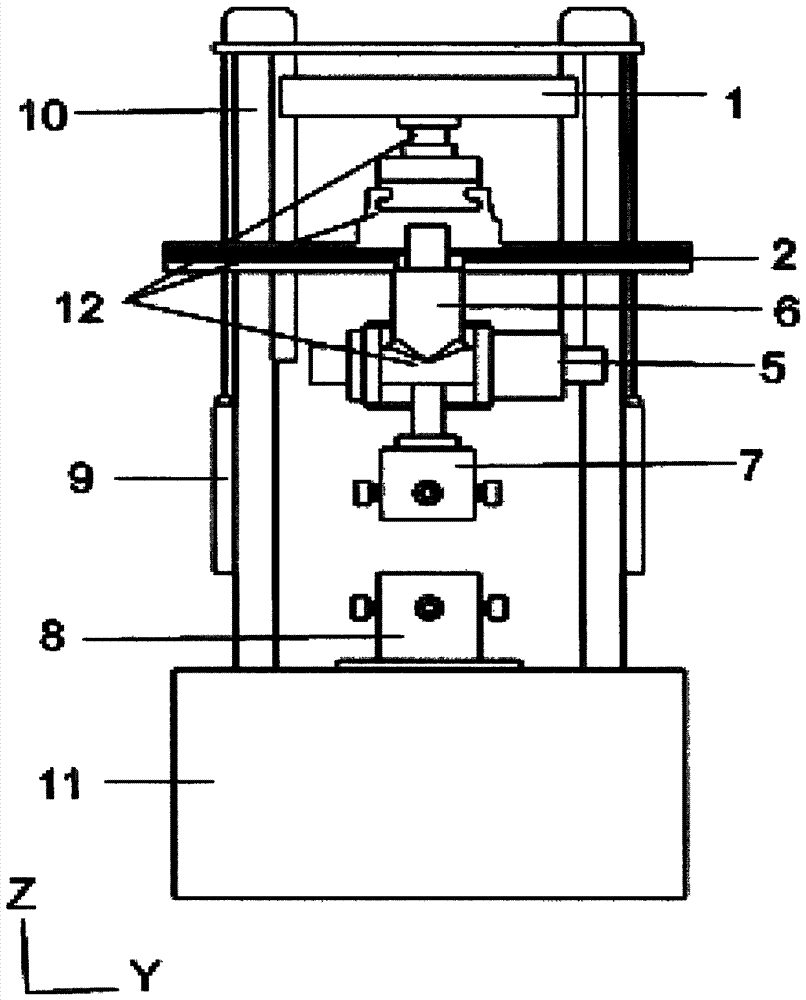

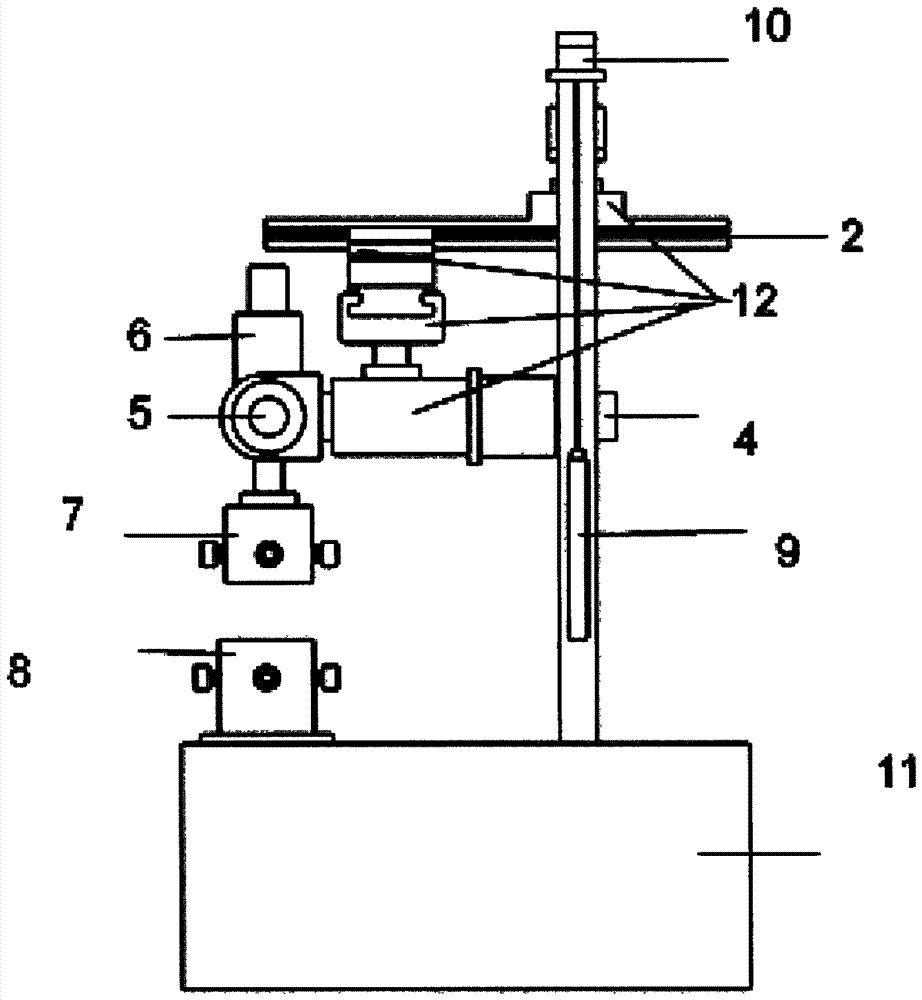

[0023] Such as figure 1 , 2 As shown, the spine biomechanical simulation test instrument is composed of three metal rods (1, 2, 3), three rotation axes (4, 5, 6), a specimen force applicator (7), a specimen fixer (8 ), two balance bars (9), a support (10), a fixed base (11) and five servo motors.

[0024] Such as( figure 1 , 2 , 3), all metal rods have scales, and the scale marks are set to 0 when the force applicator and the specimen storage container are vertically inlaid, and set to the standard state. In the state of no force applied, the force loader can move freely in 6 degrees of freedom (including front and rear, left and right, and rotation) by adjusting the servo motor: the metal rods 1, 2, and 3 can drive other moving parts in Z, X, Horizontal movement in the Y-axis direction, rotation axes 4, 5, and 6 can rotate independently, and have the ability to independently simulate 6 load components, including flexion, extension, left and right bending, and left and rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com