Working condition monitoring and fault diagnosis method for mechanical equipment

A technology for mechanical equipment and fault diagnosis, applied in the direction of testing, measuring devices, instruments, etc. of machine/structural components, which can solve the problem of rarely considering the interconnection, the useful information of time domain parameters is not fully excavated and utilized, and it is difficult to mechanically Reasonable prediction of equipment operating conditions and other issues to achieve low-cost results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

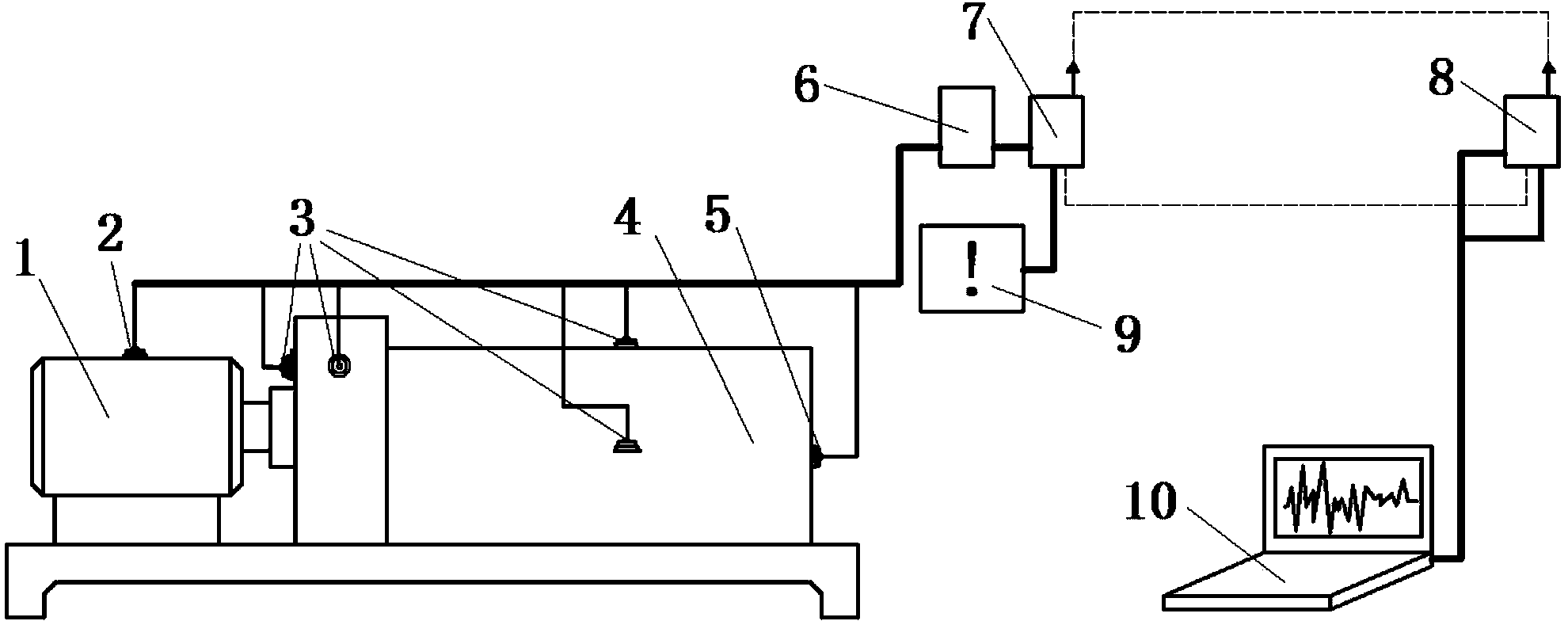

[0034] Referring now to the schematic diagram, combined with a test example of a gear transmission system, the implementation of this monitoring method and the application of this signal processing technology will be described.

[0035] 1) Composition of the device

[0036] like figure 1 As shown, the mechanical equipment in this embodiment is the GLS-II gear efficiency test system produced by Hangzhou Xingchen Science and Education Equipment Co., Ltd., and the vibration signal of the equipment is collected by the UBOX-20016 blasting vibration recorder.

[0037] The speed of the gear efficiency test system can be flexibly adjusted through the "rotational speed adjustment knob", and the output torque of the system is adjusted by the number of weights placed on the force arm, which can be changed between 0-8 weights, each The weight of the weight is 1 kg. The number of weights on the hook multiplied by the length of the cantilever is the output torque of the transmission syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com