All-sealed lamp

A fully-sealed, lamp technology, applied in lighting applications, lighting and heating equipment, office buildings, etc., can solve the problems of high cost, many assembly processes, and many components, and achieve fewer assembly processes, fewer components, and lower costs. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

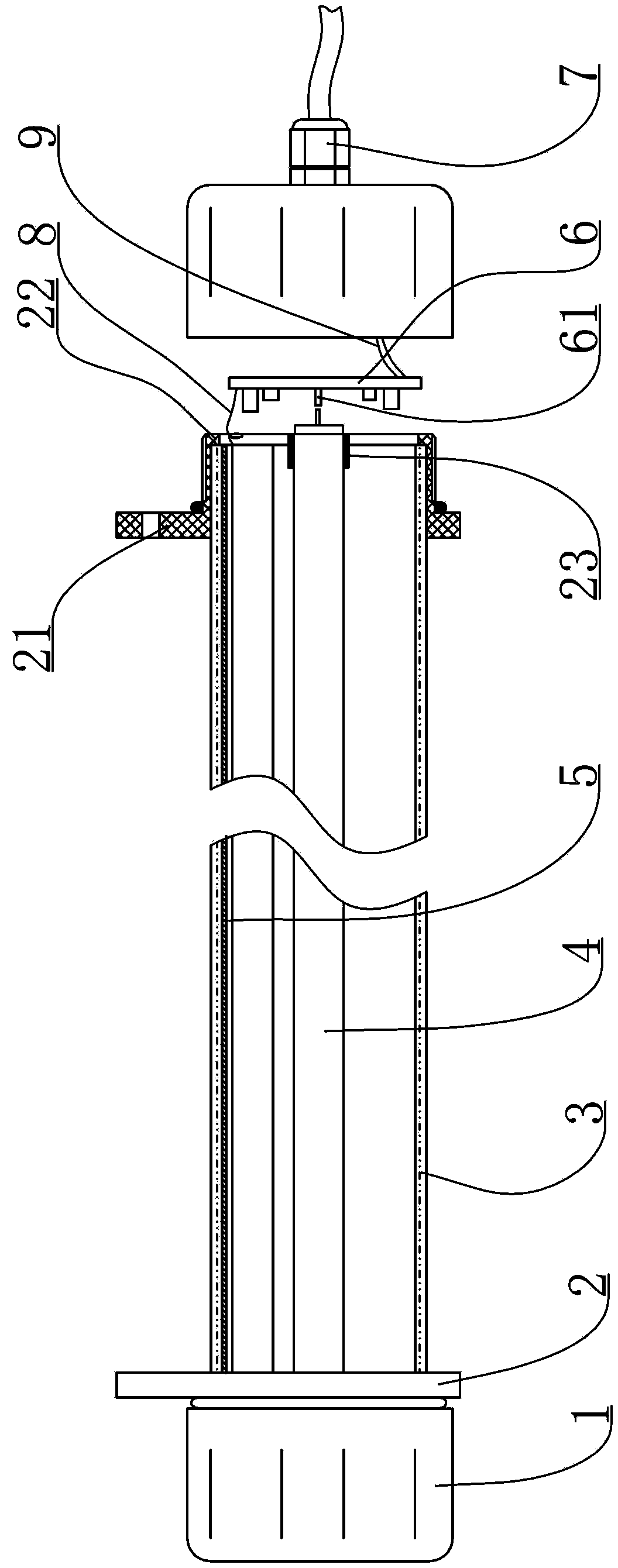

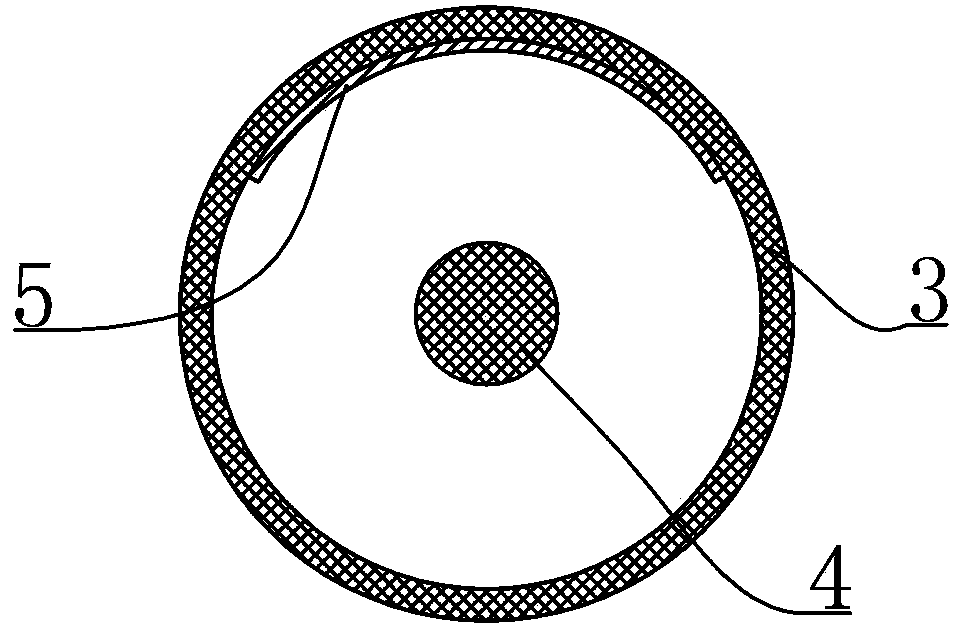

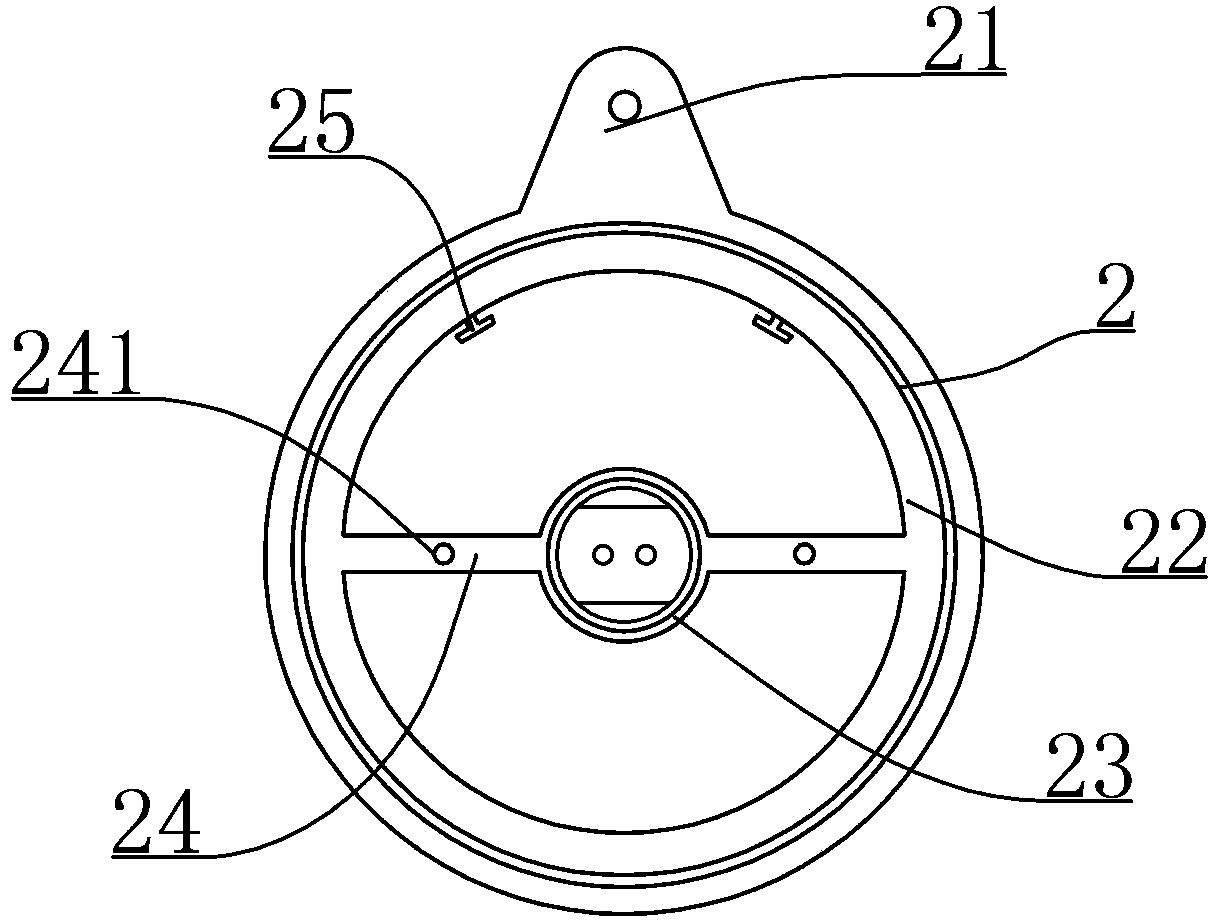

[0024] according to Figure 1 to Figure 5 As shown, a fully sealed lamp described in this embodiment includes a transparent cover tube 3, respectively fixedly connected to the end seats 2 at both ends of the cover tube 3, and an end cover 1 that is sealed and connected to each end seat 2. The lamp tube 4 and the drive circuit in the closed space formed by the cover tube 3, the end seat 2, and the end cover 1, and the wire seal 7 arranged on an end cover 1, the drive circuit is separately arranged on two circuit boards 6 Above, the two circuit boards 6 are respectively located in the two end seats 2 , and the two circuit boards 6 are respectively provided with electrical jacks 61 which are mated with the lamp caps of the lamp tube 4 . The outer wall of the end base 2 is provided with external threads, the end cover 1 and the end base 2 are connected by threads, and a sealing rubber ring is arranged between the end base 2 and the end cover 1 . The end seat 2 is also provided wi...

Embodiment 2

[0034] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that the lamp tube radial positioning ring 23 and the connecting rod 24 are not provided in the end seat, the circuit board 6 is circular, and its diameter is equivalent to the inner diameter of the end cover 1, and the end cover 1. An elastic stopper 11 is provided at a corresponding position on the inner periphery. After the end cover 1 is screwed onto the end seat 2, the circuit board 6 is clamped between the end seat 2 and the elastic stopper 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com