Rubber cup of automobile brake

A technology for rubber cups and automobile brakes, which is applied to engine components, engine seals, mechanical equipment, etc. It can solve problems such as wear resistance and sealing performance reduction, poor process precision control, and inner lip thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

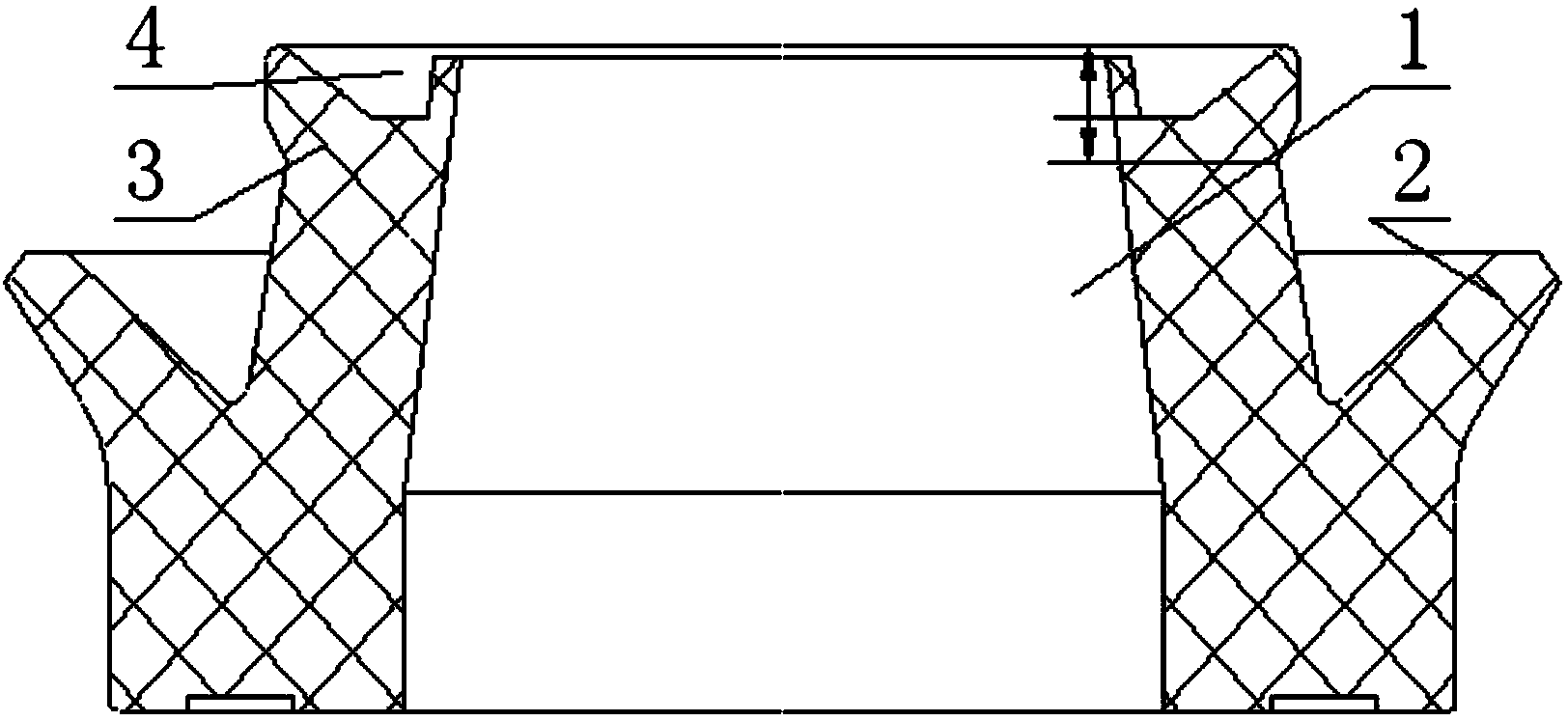

[0012] Embodiment 1 of the present invention: automobile brake rubber cup, making rubber bowl 1, outer lip 2 and inner lip 3 are arranged on bowl 1, groove 4 is made on inner lip 3, groove The section of 4 is trapezoidal or V-shaped. The depth of the groove 4 is 1 / 4-3 / 4 of the height of the inner lip 3 .

Embodiment 2

[0013] Embodiment 2 of the present invention: automobile brake rubber cup, making rubber bowl 1, outer lip 2 and inner lip 3 are arranged on bowl 1, groove 4 is made on inner lip 3, after testing , the cross-section of the groove 4 is trapezoidal, and a ring-shaped protrusion is formed at the end of the inner lip 3, which has a better effect of reducing the interference fit. The depth of the groove 4 is 1 / 3-2 / 3 of the height of the inner lip 3, which can maintain the strength of the inner lip.

Embodiment 3

[0014] Embodiment 3 of the present invention: automobile brake rubber cup, make rubber bowl 1, have outer lip 2 and inner lip 3 on bowl 1, make groove 4 on inner lip 3, groove The section of 4 is trapezoidal, and the depth of the groove 4 is 1 / 2 of the height of the inner lip 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com