Dyeing method of terylene, acrylic fiber, viscose glue and spandex blended fabric

A blended fabric and dyeing method technology, which is applied in the dyeing field of acrylic, polyester, viscose and spandex blended fabrics, can solve the problem of different staining effects of acrylic fiber and viscose fiber, affecting the stable control of the production process, and the waste of dyeing energy is too large and other problems, to achieve the effect of reducing the running time too long, shortening the production process, and stabilizing the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

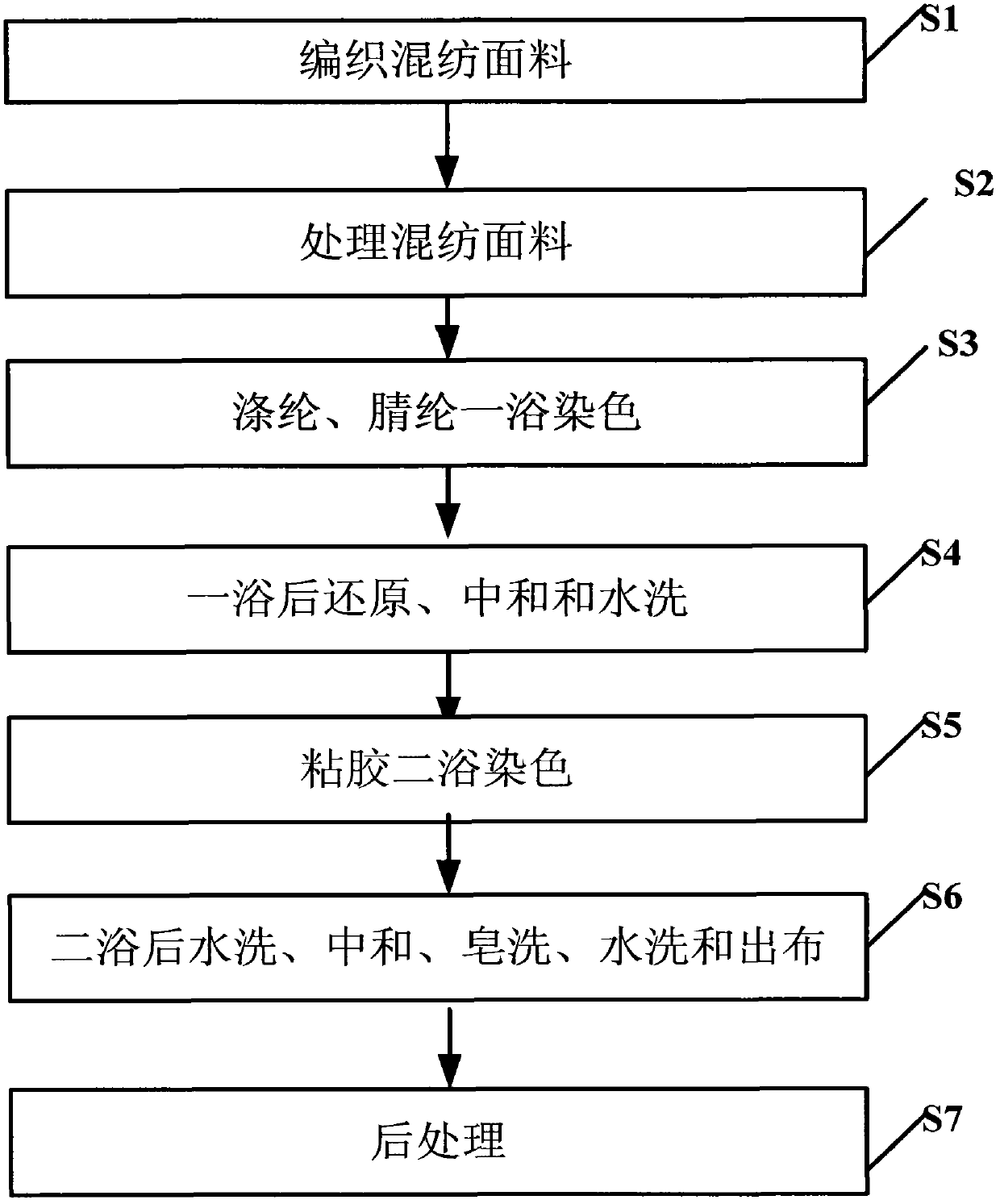

[0087] The dyeing method of polyester, acrylic fiber, viscose glue and spandex blended fabric, comprises the following steps,

[0088] (1) Woven blended fabrics: Weaved blended fabrics containing polyester, acrylic, viscose and spandex. The blended fabric contains the following components by weight: 30% polyester, 45% acrylic, 15% viscose, and 10% spandex.

[0089] (2) Processing blended fabrics: pre-setting the blended fabrics in step (1) and seaming them together.

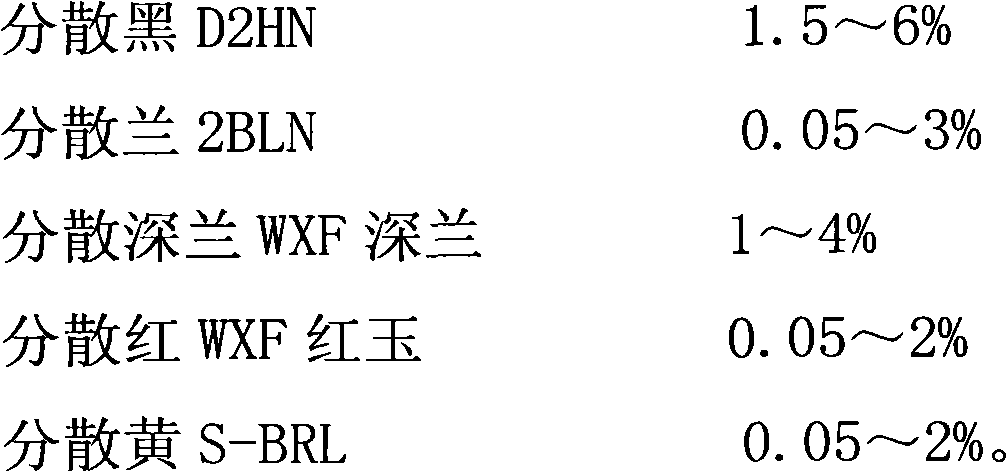

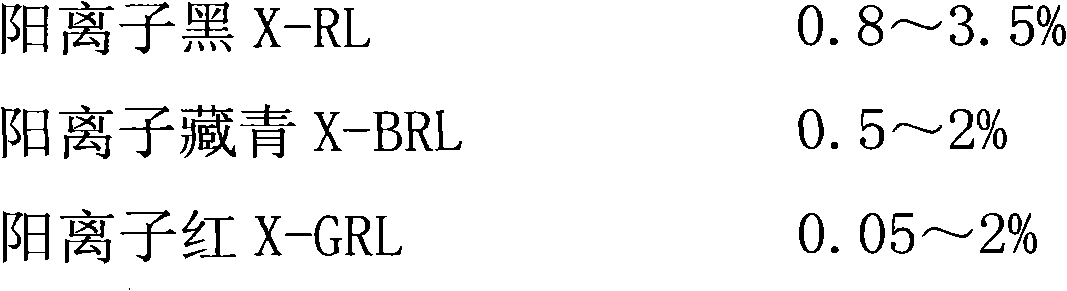

[0090] (3) One-bath dyeing of polyester and acrylic fibers: put the blended fabric treated in step (2) into cold water and heat up to 30°C, add Ao mixture 8108, degreaser 115C, high temperature leveling agent, acrylic leveling agent, dyeing acid in sequence DA, disperse dyes, and cationic dyes, then heat up to 120°C for 30 minutes, then cool down to 100°C for 20 minutes, then cool down to 70°C, take samples for comparison, then cool down to 60°C and stop for drainage, add cold water and run for 5 minutes to drai...

Embodiment 2

[0117] The dyeing method of polyester, acrylic fiber, viscose glue and spandex blended fabric, comprises the following steps,

[0118](1) Woven blended fabrics: Weaved blended fabrics containing polyester, acrylic, viscose and spandex. The blended fabric contains the following components by weight: 40% polyester, 35% acrylic, 20% viscose, and 5% spandex.

[0119] (2) Processing blended fabrics: pre-setting the blended fabrics in step (1) and seaming them together.

[0120] (3) One-bath dyeing of polyester and acrylic fibers: Put the blended fabric treated in step (2) into cold water and heat up to 50°C, add Ao mixture 8108, degreaser 115C, high temperature leveling agent, acrylic leveling agent, dyeing acid in sequence DA, disperse dyes, and cationic dyes, then heat up to 140°C for 30 minutes, then cool down to 110°C for 20 minutes, then cool down to 90°C, take samples for comparison, then cool down to 80°C, stop and drain, add cold water and run for 5 minutes to drain.

[0...

Embodiment 3

[0148] The dyeing method of polyester, acrylic fiber, viscose glue and spandex blended fabric, comprises the following steps,

[0149] (1) Woven blended fabrics: Weaved blended fabrics containing polyester, acrylic, viscose and spandex. The blended fabric contains the following components by weight: 34% of polyester fiber, 41.3% of acrylic fiber, 17.7% of viscose fiber and 7% of spandex. The polyester is 75D polyester filament, the acrylic and viscose form 40S / 1 acrylic viscose blended yarn, and the spandex is 20D spandex. Thread length: polyester filament 30cm / spandex yarn 11.5cm / acrylic viscose blended yarn 29cm (100G). Weaving method: one way of polyester filament + spandex, another way of acrylic viscose blended yarn + spandex.

[0150] (2) Processing blended fabrics: pre-setting the blended fabrics in step (1) and seaming them together.

[0151] (3) One-bath dyeing of polyester and acrylic fiber: put the blended fabric treated in step (2) into cold water and heat up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com