Structure of furnace body of cracking furnace

A furnace structure and cracking furnace technology, which are applied in cracking, non-catalytic thermal cracking, petroleum industry, etc., can solve the problem of uneven thermal field distribution of flue gas flow field in the furnace, improve thermal field distribution, increase operation cycle, The effect of uniform heat distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

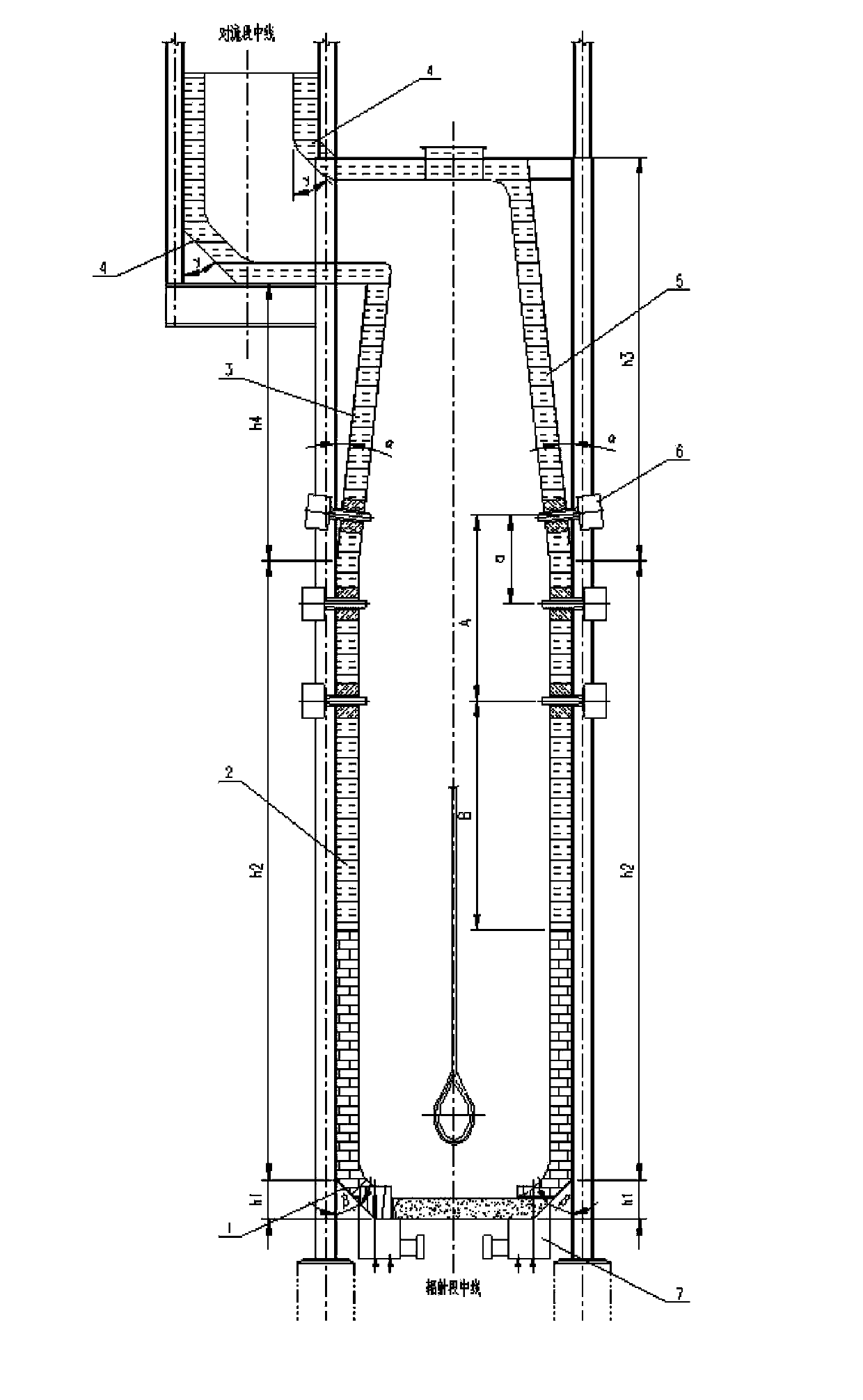

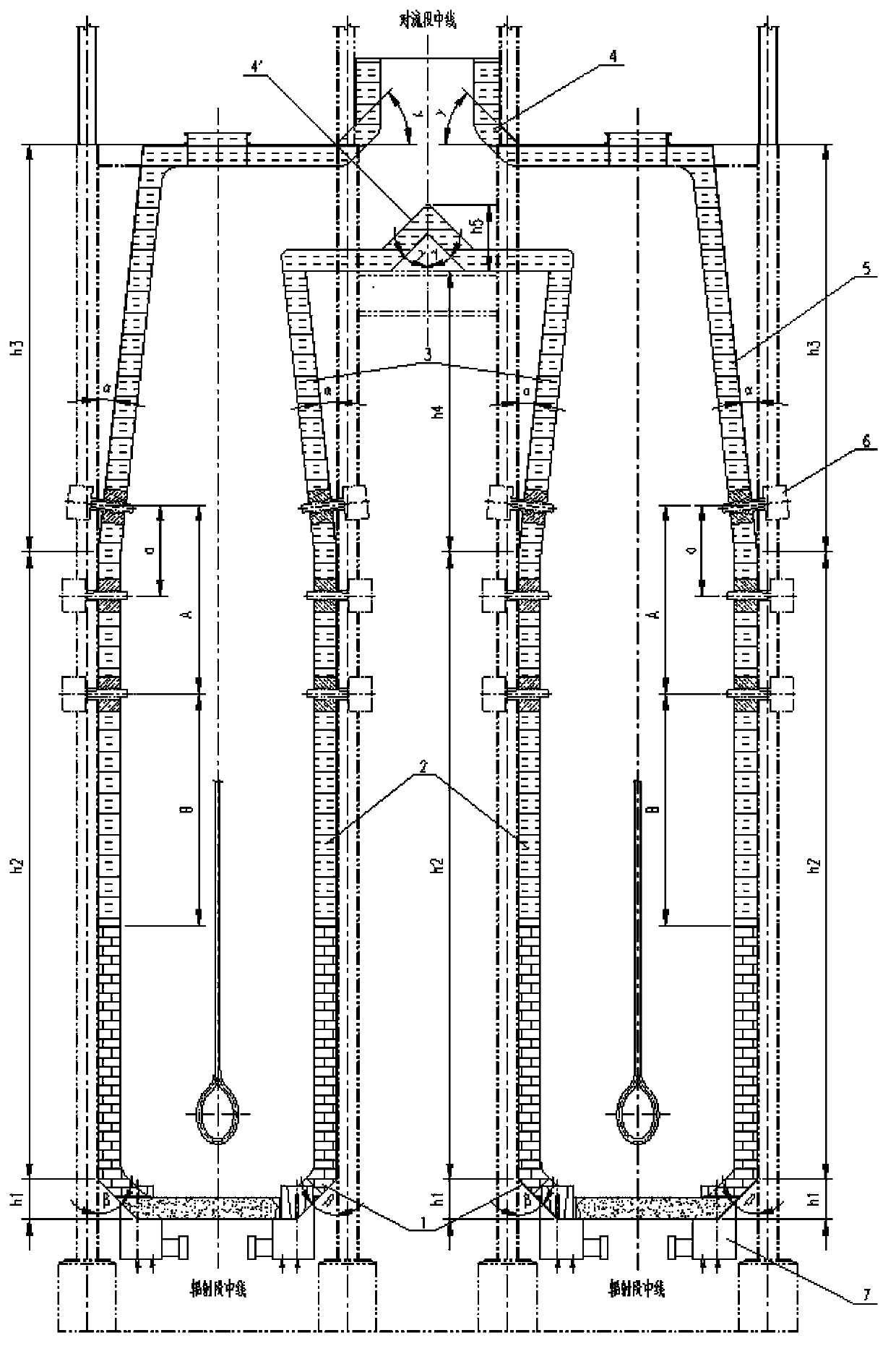

[0034] ⑴. For a single-hearth box-type cracking furnace: such as figure 1 As shown, the radiant chamber is composed of a furnace, one side wall is high and the other is low. The walls on both sides are composed of constriction structure, straight wall and slope transition structure from top to bottom, and the transition section is composed of slope transition structure. The angle between the inclined wall and the center line of the radiation section is α, the angle between the furnace bottom transition slope and the center line of the radiation section is β, and the angle range is 0°<α≤20°, 0°<β≤45°; the slope of the transition section The included angle with the centerline of the radiant section is γ, and the angle range of the included angle γ is 0°<γ≤45° to ensure the flue gas flow pattern of the radiant furnace. At the bottom of the radiant furnace, the distance between the burner and the furnace center line is L, the distance between the side wall burners is a, the number...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com