Steel and aluminum composite conductor rail with dovetail groove

A technology of steel-aluminum composite and dovetail groove, which is applied in the direction of power rails, power lines, transportation and packaging, etc., can solve the problem that the contact surface of stainless steel cannot be maintained, and achieve the effect of strong binding force, good safety and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below the present invention is further described in conjunction with the embodiment in the accompanying drawings:

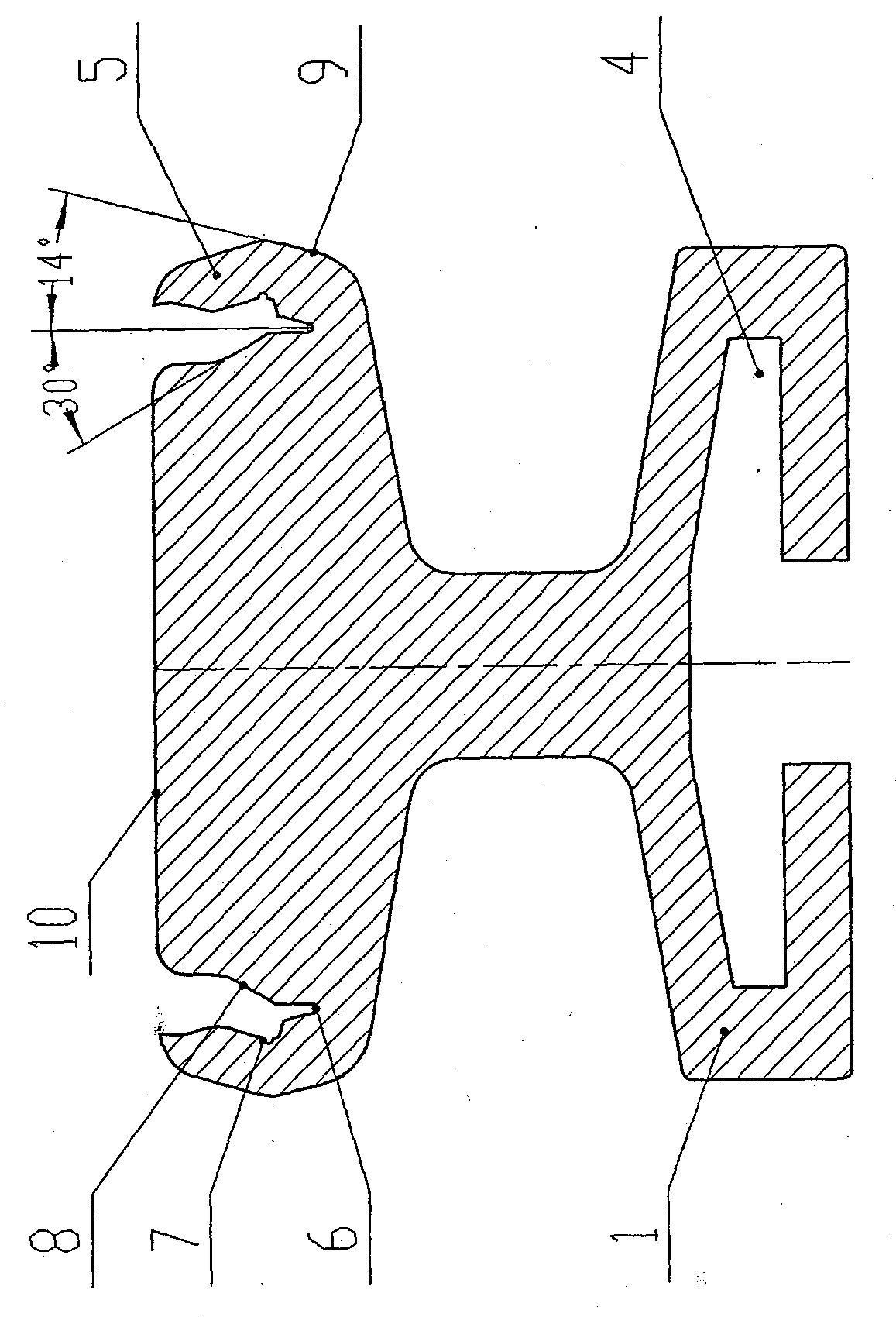

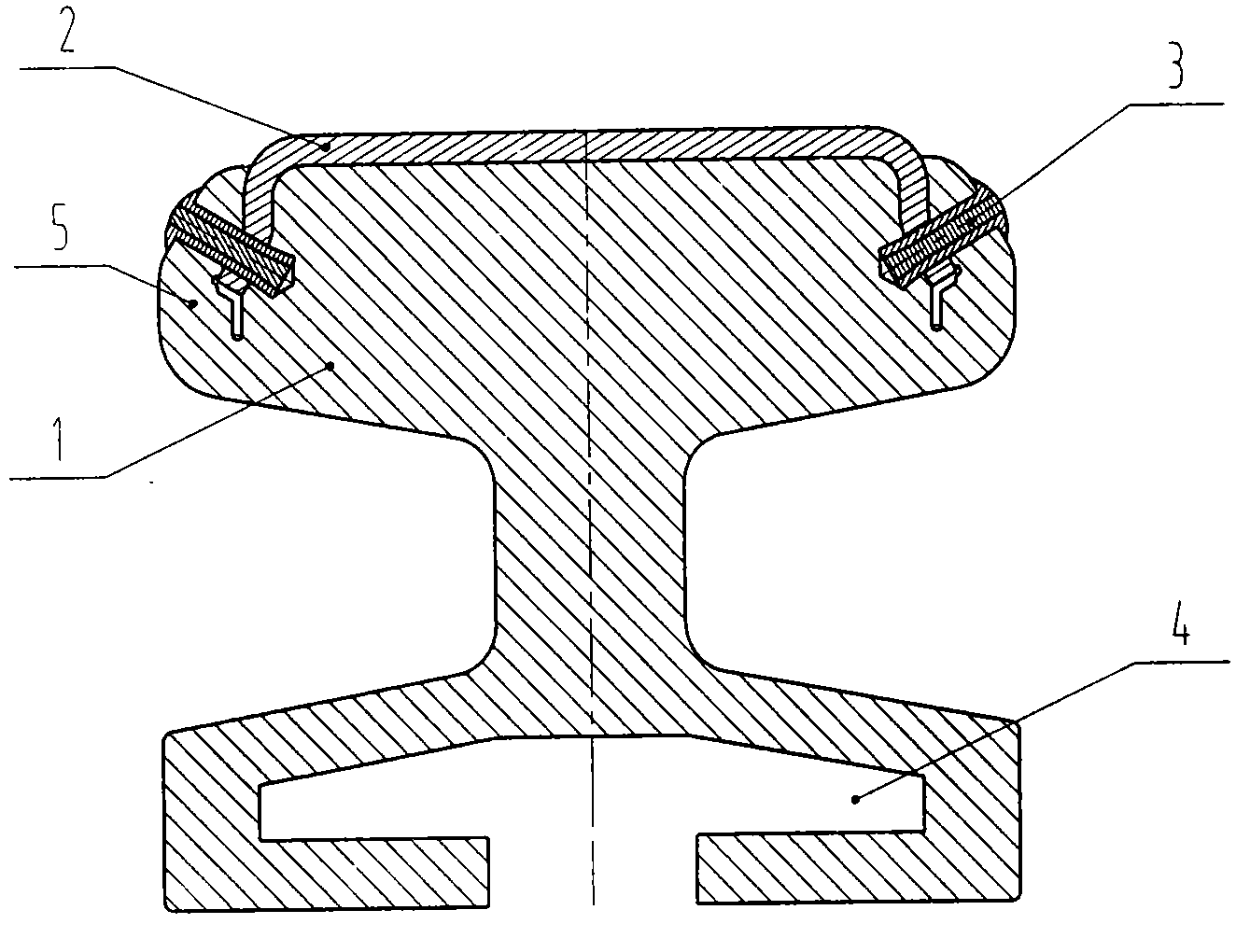

[0019] exist figure 1 Among them, the right side of the aluminum rail 1 is a stainless steel groove 2, and a dovetail groove 4 is further dug out on the left side. The upper and lower lugs 5 on the right side of the aluminum rail 1 tightly embrace the flange of the stainless steel tank 2, and then lock the lugs 5 and the stainless steel tank 2 with stainless steel blind rivets to form a steel-aluminum composite conductive rail 15 through which direct current is positively charged.

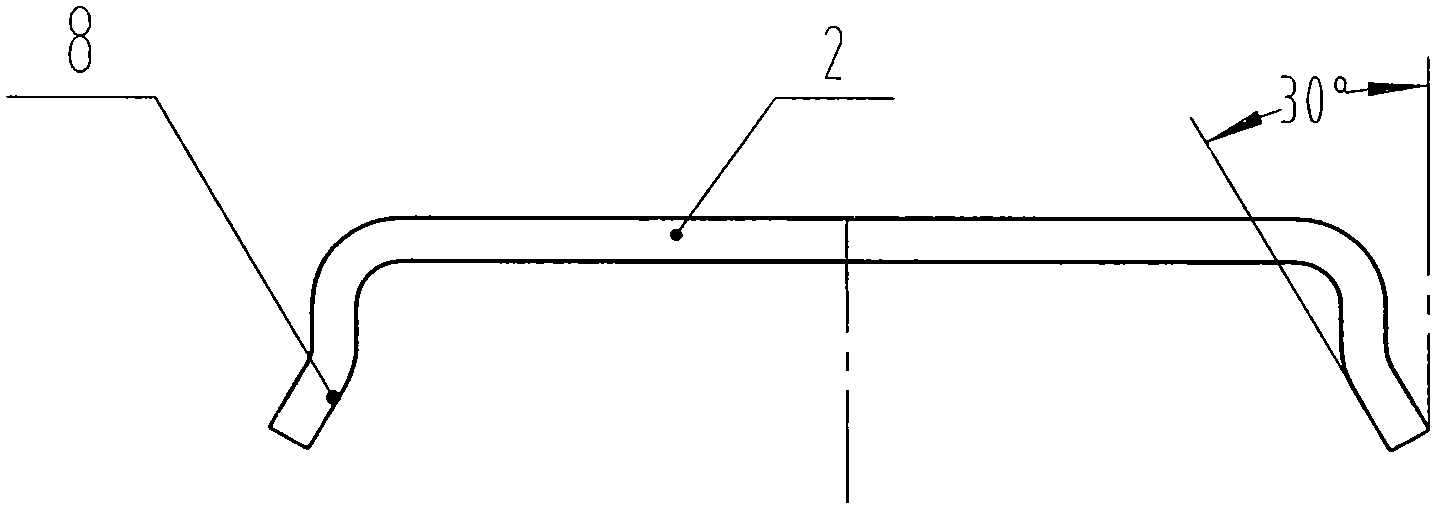

[0020] exist figure 2 The middle aluminum rail 1 is combined with the first two lugs 5 and turned 14° to the outside, and the image 3 After the inner side surface of the stainless steel tank 2 is close to the top surface 10 of the aluminum rail 1, the inner slope 8 of the stainless steel tank 2 with an angle of 30° coincides with the inner slope 8 on the aluminum rail 1. At...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com