Centering adjustment method of V block center and work head center of grinding machine tool

A centering adjustment and working head technology, which is applied to the parts of grinding machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc., can solve the problems of difficult machine adjustment and long precision retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

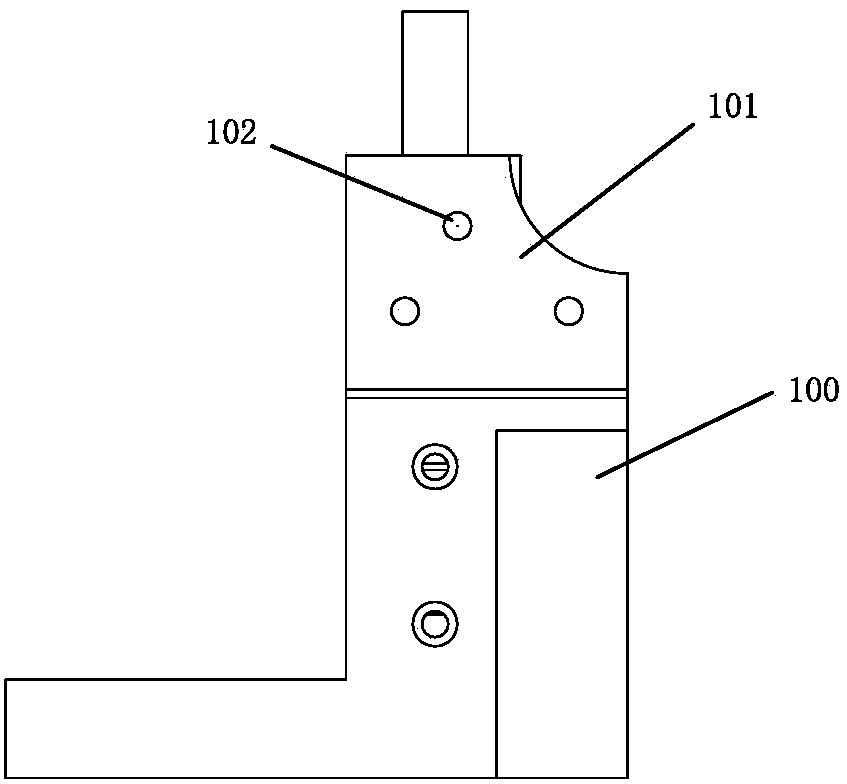

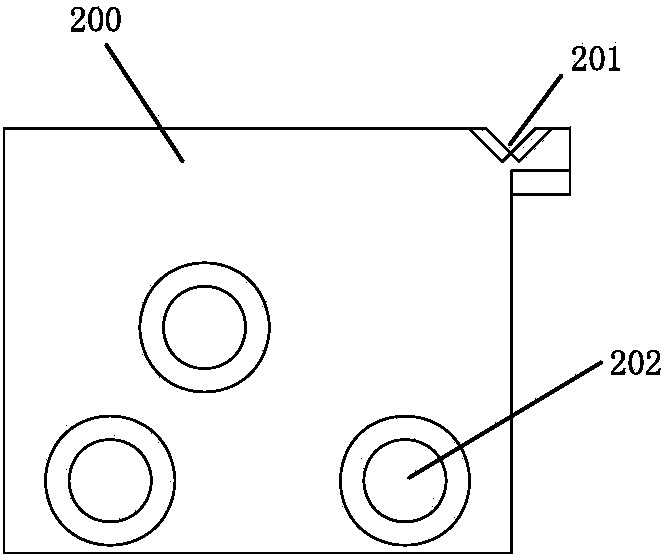

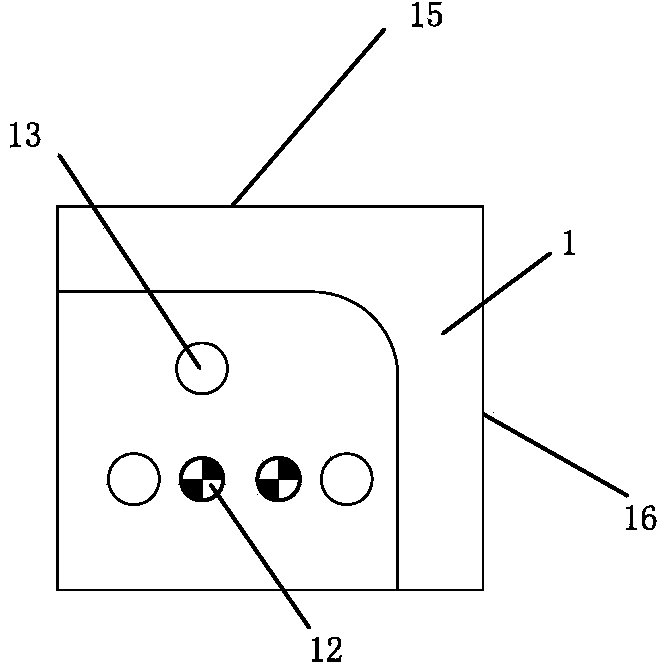

[0034] Examples, see Figure 3 to Figure 13 As shown, the technical solution adopted by the present invention to solve its technical problems is: the center of the V block of a grinding machine tool is aligned with the center of the working head (the working head refers to the mechanism used to clamp the bar on the equipment to rotate) Adjustment methods include:

[0035] Preset a standard block 1 that meets a certain precision value, the standard block 1 has a first side 11, and the first side 11 is set to be used with the original support cylinder of the machine tool (support cylinder refers to the equipment used for installation V block, and press the bar when the bar rotates, and the oil cylinder that acts as an auxiliary support) is the first installation surface that matches the V block installation surface. The first installation surface 11 is provided with a first positioning pin hole 12. The first mounting surface 11 is also provided with the first mounting hole 13 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com