An orderly automatic movement and fixed-point pouring system of iron mold sand-covered casting

A technology of automatic movement and sand-coating of iron molds, which is applied in foundry workshops, casting equipment, manufacturing tools, etc., can solve the problems of high labor intensity, easy burns for operators, and pollution of pouring sites by manual push boxes, so as to improve production efficiency and Work quality, elimination of molten iron splash card wheel, and the effect of improving the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

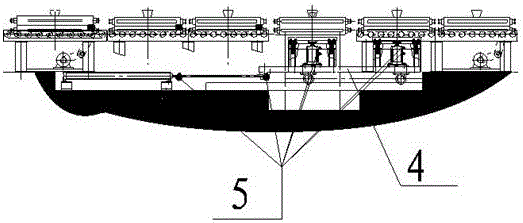

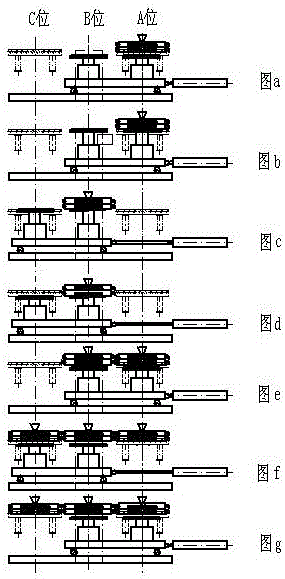

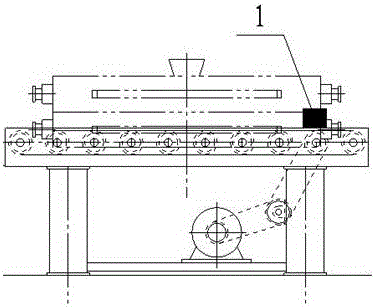

[0016] An iron mold sand-covered casting mold orderly automatic movement and fixed-point pouring system is composed of a photoelectric switch 1, a motorized raceway unit 2, a No. 1 transfer trolley 3, a pouring trolley 4, a proximity switch 5, a No. 1 motorized track 6, Composed of No. 2 motor track 7, No. 2 transfer trolley 8, PLC electrical control cabinet 9, casting cooling track 10, casting exit track 11, No. 3 transfer trolley 12, No. 1 transmission track 13, and No. 2 transmission track 14, its characteristics It is: No. 1 motorized track 6 and No. 2 motorized track 7 are connected by a plurality of motorized raceway units 2, and No. 1 transfer trolley 3 is on the No. 1 transmission track 13, the No. 2 transmission track 14, and the No. 1 motorized track along a specific track. 6 and one end of No. 2 motor track 7, No. 2 transfer car 8 is at the other end of No. 1 motor track 6 and No. 2 motor track 7 along the specific track, and No. 3 transfer car 12 is at No. 1 drive t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com