Automatic forging system of high-speed forging oil press

A hydraulic press, automatic technology, applied in the direction of the hammer drive device, etc., can solve the problems of long manual operation time, difficulty in guaranteeing the stability of forging processing quality, and high labor intensity of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

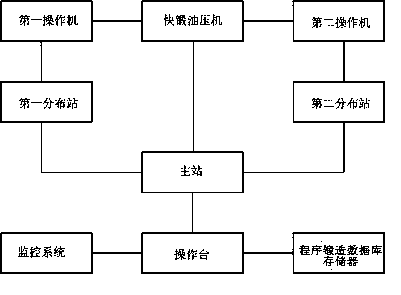

[0024] refer to figure 1 , the automatic forging system for fast forging hydraulic press of the present invention includes an operation console, a program forging database memory, a first distribution station, a second distribution station, a master station, a first manipulator, a second manipulator, a fast forging hydraulic press, and a monitoring system.

[0025] According to the parameters of the input blank and forging finished product, the console selects the corresponding forging process from the program forging database memory, and transmits the forging process to the master station.

[0026] The master station distributes corresponding action commands to the first distribution station, the second distribution station and the fast forging hydraulic press according to the forging process transmitted by the operation platform, so as to control the first manipulator, the second manipulator and the fast forging hydraulic press to complete the corresponding mechanical operati...

Embodiment 2

[0034] According to the automatic forging system of quick forging hydraulic press described in Embodiment 1, before starting to forge the forging, by inputting the parameters of the blank and the parameters required by the finished forging on the console, the corresponding automatically generated parameters are selected in the program forging database memory. Forging process.

[0035] The operation table transmits the selected forging process to the main station through the network cable. The main station plays a central role in the automatic forging system of the quick forging hydraulic press, and completes the control of the entire automatic forging process through electrical circuits. The master station is responsible for transmitting the command signal of the forging process program to the quick forging hydraulic press, or to the first manipulator and the second manipulator respectively through the first distribution station and the second distribution station.

[0036] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com