A Method for Controlling the Rough Strip Width of a Hot Tandem Mill Based on Multiple Heating Furnaces

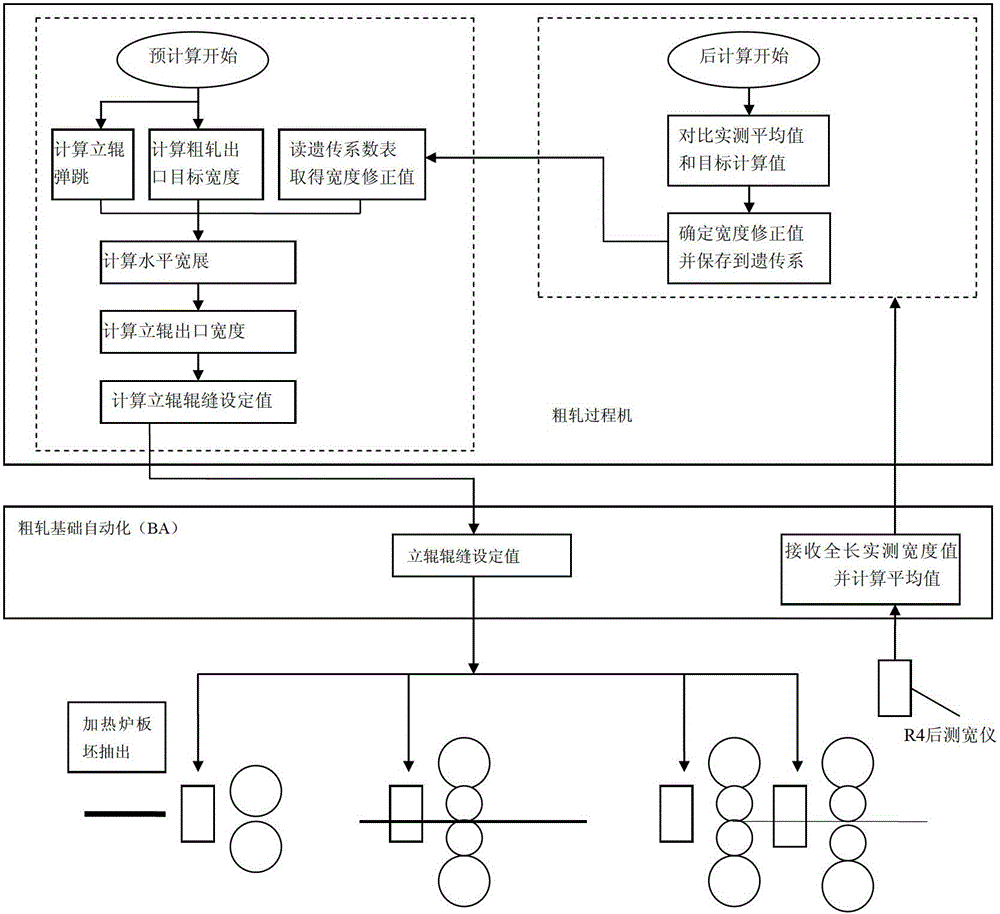

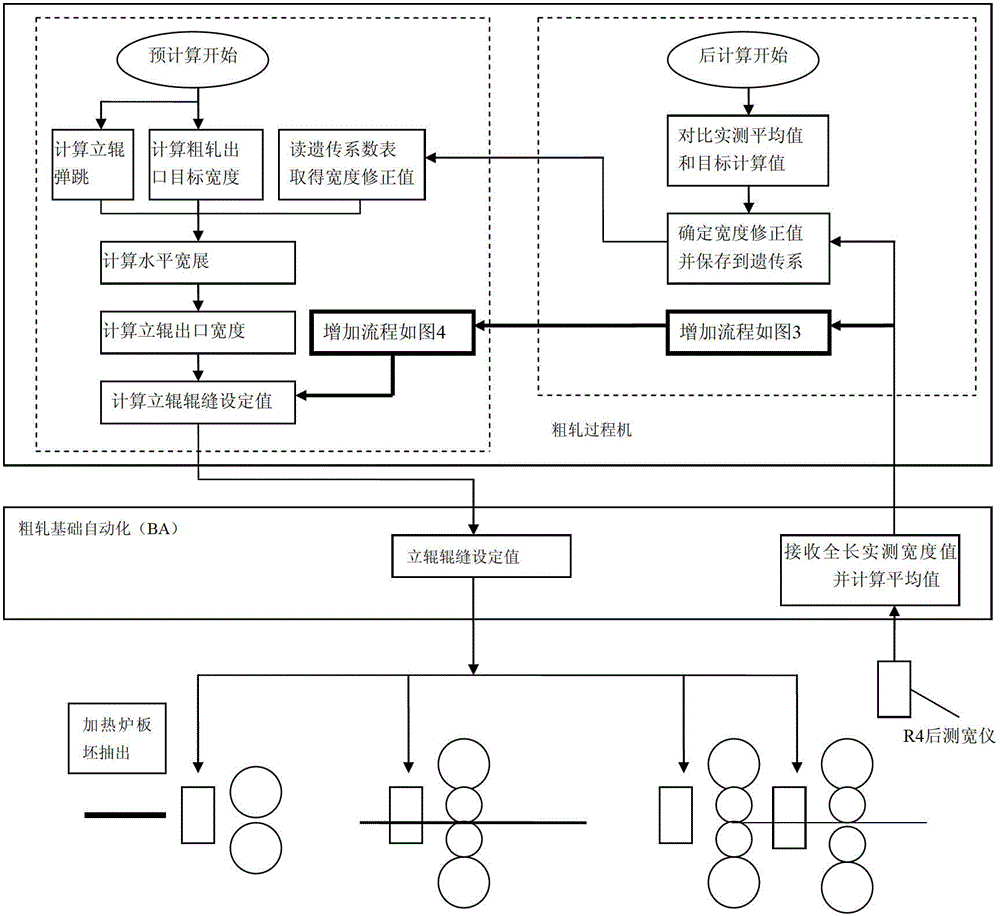

A hot continuous rolling mill and width control technology, which is applied in the direction of metal rolling stands, metal rolling mill stands, etc., can solve the problems of not taking into account the width deviation of the rough rolling outlet, frequent fluctuations of the rough rolling outlet width, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0175] Precomputation stage:

[0176] Take strip steel 3050100100 as an example: finished product width pri_width: 1500mm, fixed margin add_width: 8mm, target width aim_width=1500+8=1508mm, this piece of steel comes from 3# heating furnace, and the rough rolling global width genetic coefficient width_corr is calculated in the model : -8mm, vertical roll gap zero correction value zero_corr: 3mm, vertical roll wear edger_wear: -0.8mm, vertical roll bounce edger_iKNflexsioKN: 0.5

[0177] The process of calculating the furnace number-related width correction value width_corr_fur is as follows:

[0178] By default, the model takes furnace No. 1 as the benchmark furnace number, and obtains the genetic coefficient table related to the furnace number:

[0179]

[0180] Furnace number-related width correction value Width_corr_fur=base furnace number width correction coefficient corr_fur[1]-current strip furnace number-related width correction coefficient corr_fur[3]=-1.5-(-3)=1.5m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com