Automatic Control Method of Strip Width in Hot Continuous Rolling Finishing

A technology of hot continuous rolling and strip steel, applied in the direction of metal rolling stand, metal rolling mill stand, etc., can solve the problems of difficulty in maintaining strip width consistency, inability to take into account, affecting the stability of finishing rolling system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

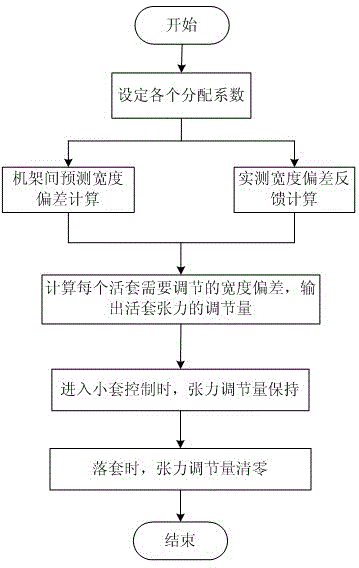

Image

Examples

Embodiment 1

[0071] Such as figure 1 As shown, the hot continuous rolling finishing system usually has seven stands, that is, the 1st to 7th stands 11 to 17, and the strip width prediction module is set at the exit of the first 6 stands, that is, the 1st to 6th strip Width prediction modules 51~56; a looper is set between two adjacent racks, and there are 1st~6th loopers 21~26 in total, and each looper is independently equipped with a tension adjustment module, that is, the 1st~6th Tension adjustment modules 41~46, the rough rolling area 9 before the hot continuous rolling and finishing rolling system, the inlet pyrometer 30 and the vertical roll 10 before finishing rolling are installed at the entrance of the hot continuous rolling and finishing rolling system, and the exit of the hot continuous rolling and finishing rolling system There is a width measuring instrument 31 and an outlet pyrometer 32, the width measuring instrument 31 is connected with the tension adjustment module through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com