A dual-purpose steamer and its working control method

A technology for steaming boxes and control components, which is applied in the field of dual-purpose steaming boxes and its work control. It can solve the problems of long time for heat to penetrate into food, high heating temperature, and affecting taste, so as to enrich food life and increase cooking temperature. , fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

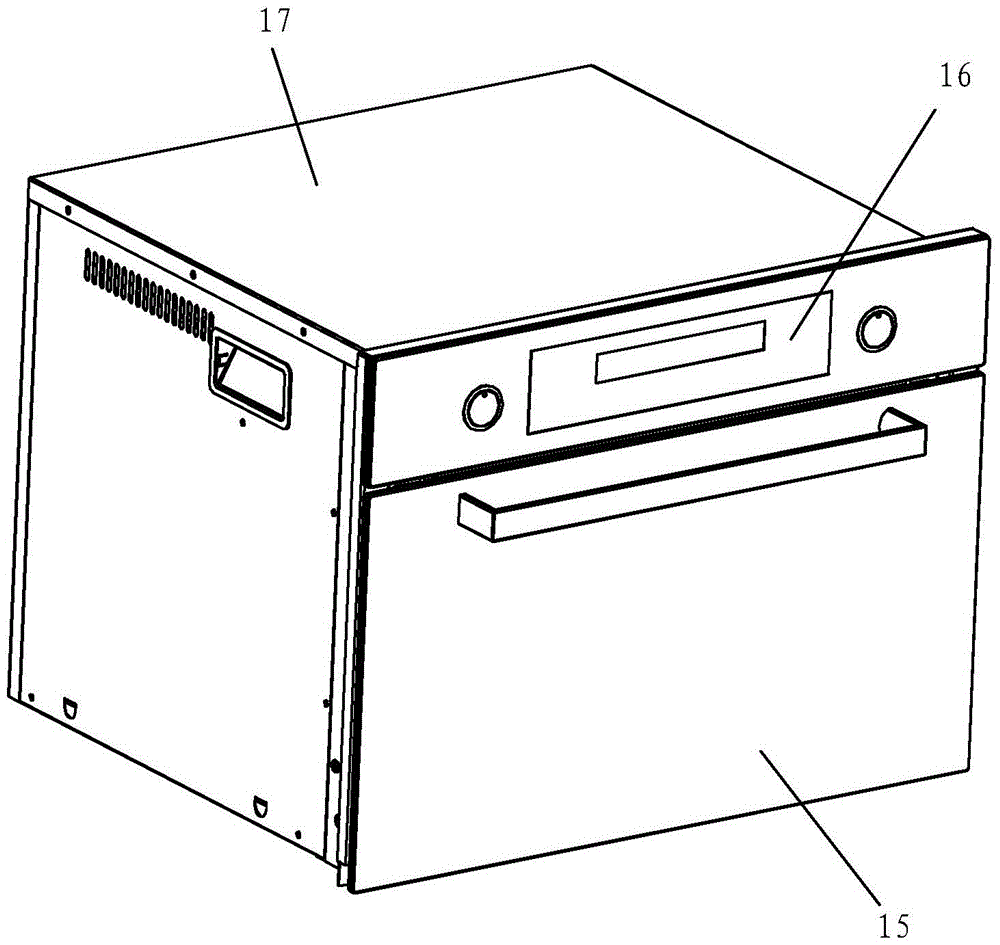

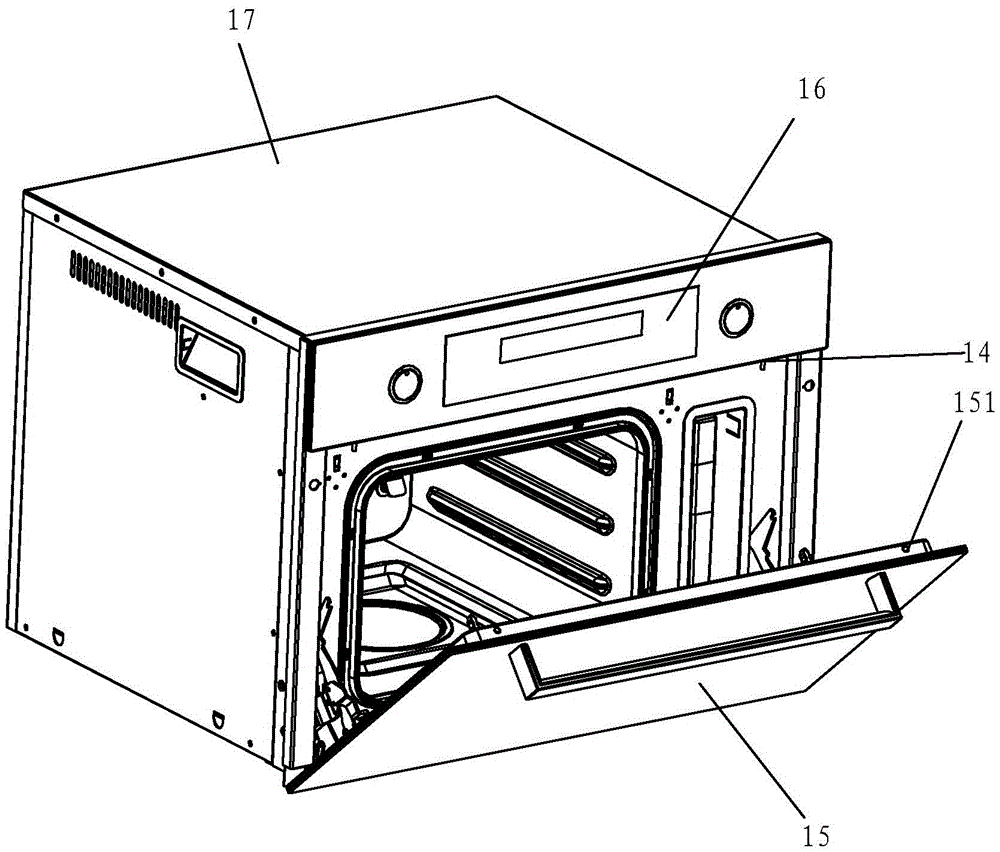

[0030] Such as Figure 1~4 The shown dual-purpose steam box includes a box body 17, which is provided with an inner container assembly having a cooking chamber 13, and the box body 17 is provided with a box door 15 for opening the cooking room, and the box body 17 is also provided with a A steam generator 8 communicated with the cooking chamber, a water level control box 4 communicated with the steam generator 8, and a water tank 1 communicated with the water level control box, wherein the cooking chamber is provided with a temperature sensor 9, and the inner container assembly is provided with The steam valve 11 that makes the cooking chamber communicate with the outside, the electromagnetic lock 14 for locking the box door is installed on the inner container assembly, and correspondingly, the box door 15 is provided with a lock hole 151 that cooperates with the electromagnetic lock lock rod, The box is provided with a control assembly 16 capable of outputting normal pressure...

Embodiment 2

[0039] Different from the first embodiment, the temperature sensor 9 is replaced by a pressure sensor 12 .

[0040] When the control component 16 outputs the pressure steaming working mode, the control component 16 collects the pressure value of the pressure sensor 12 in real time at the same time. When the pressure in the cooking chamber reaches the first pressure value preset by the control component, the control component 16 outputs a control signal to the steam generator. The heating element of the steam generator 8 stops heating so as to stop generating steam. When the pressure in the cooking chamber reaches the second pressure value preset by the control assembly, the control assembly 16 outputs a control signal to the heating element of the steam generator 8 so that the steam generator continues to heat and supplement Steam, so that the food is heated repeatedly; the first pressure value here is generally set to the atmospheric pressure value; the second pressure value i...

Embodiment 3

[0042] Different from the first embodiment, the cooking chamber is provided with a temperature sensor 9 and a pressure sensor 12 at the same time.

[0043] In the case of control module output pressure steam working mode:

[0044] When the temperature sensor 9 fails, the pressure in the cooking chamber is detected by the pressure sensor 12. When the pressure in the cooking chamber rises to the preset warning pressure value of the control assembly, the control assembly outputs a control signal to the steam generator to stop the steam generator from heating. Generate steam, and at the same time, the control component outputs a control signal to the steam valve to open the steam valve until the pressure in the cooking chamber decreases to the preset safety pressure value of the control component, and the control component outputs a control signal to the steam valve to close the steam valve; at the same time, when the cooking chamber When the pressure reaches the preset second pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com