Spring roll automatic forming device

An automatic forming and spring roll technology, which is applied in baking, dough processing, food science, etc., can solve the problems of spring rolls not being round enough, manual methods taking too much time, inconsistent size and weight, etc., achieving the same weight and liberating labor force , the effect of smooth skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

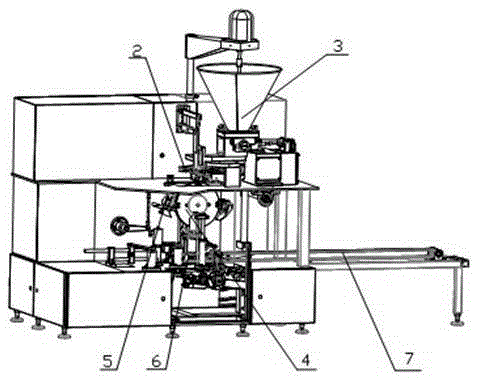

[0021] The present invention proposes a spring roll automatic forming device, such as figure 1 As shown, it includes a dough conveying fixed-length cutting mechanism, a dough claw mechanism 2, a filling mechanism 3, a semi-finished product turning mechanism 4, a coiling plate 5, a forming mechanism 6 and a conveying mechanism 7;

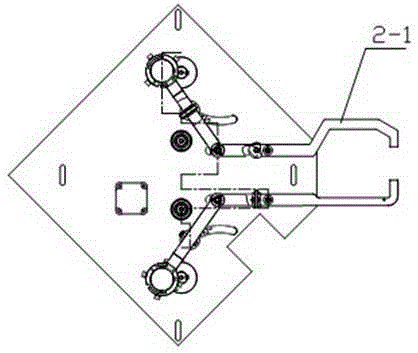

[0022] like figure 2 As shown, the dough claw mechanism includes a claw hand 2-1, which is used to pull the cut dough into the filling station;

[0023] The filling mechanism includes a filling tube that can move up and down, and the filling tube is used to quantitatively fill a corner of the cut dough surface, and press the stuffed dough part into the concave of the semi-finished product turning mechanism through the filling tube. in the tank;

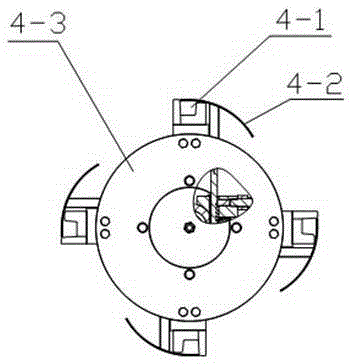

[0024] like image 3 As shown, the semi-finished product turning mechanism includes a turning turntable 4-3 capable of rotating and positioning, and four grooves 4-1 are evenly distributed on the circumf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com