Method for preparing cathode material of lithium ion battery

A technology for lithium ion batteries and cathode materials, which is applied in battery electrodes, battery recycling, circuits, etc., can solve the problems of complex types of cathode materials, reduce the demand for equipment and chemicals, reduce the addition of impurities, and reduce the preparation cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

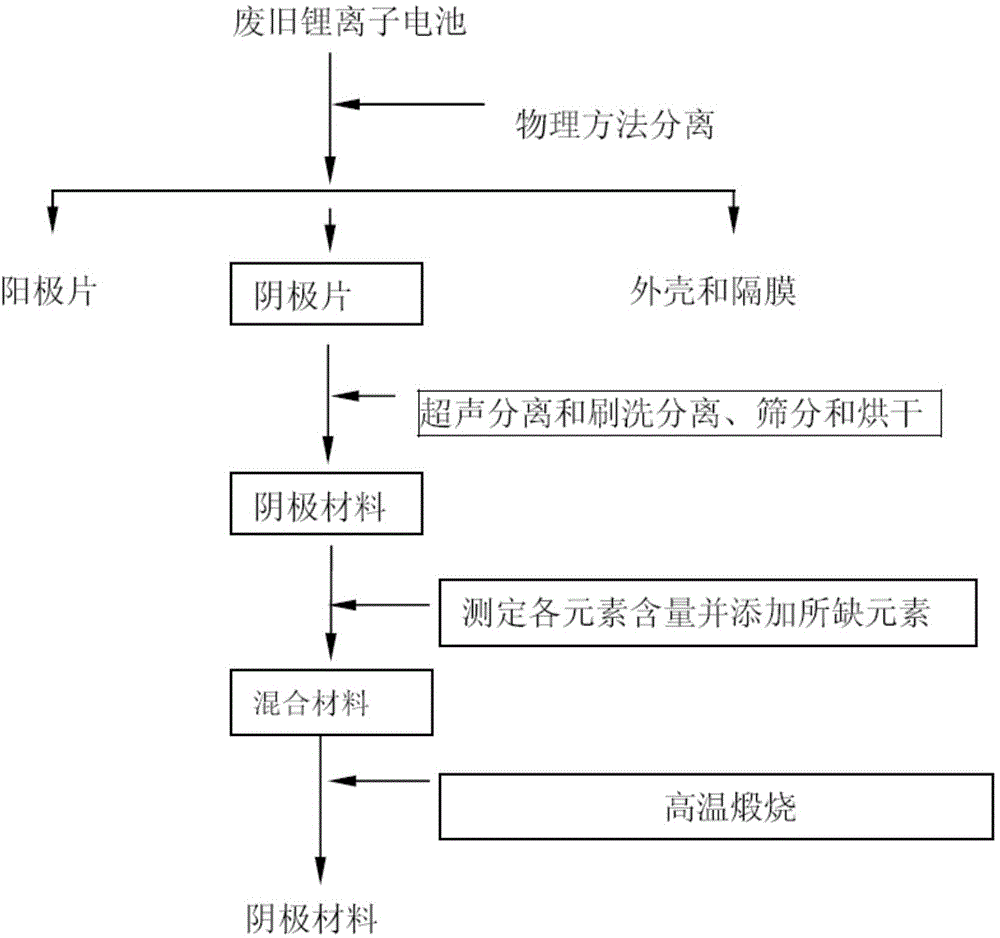

[0022] The waste lithium-ion battery to be recovered in this embodiment is a one-element lithium-ion battery whose cathode material is lithium cobalt oxide collected from the market, and the recycling flow chart is as follows figure 1 shown. The method for reclaiming the cathode material of the waste lithium-ion battery in this embodiment and then using it to prepare the cathode material of the lithium-ion battery comprises the following steps:

[0023] 1) Disassemble the battery in an anhydrous glove box, open the shell of the used battery, separate the cathode sheet of the battery from the battery, soak the cathode sheet in dimethyl carbonate, and make the electrolyte impurities contained in the cathode sheet Dissolve in dimethyl carbonate, wash away the electrolyte with dimethyl carbonate (DMC), filter again, and collect the cathode sheet. After the cathode piece is taken out, it is put into water, and the lithium cobaltate cathode material is separated from the aluminum p...

Embodiment 2

[0027] The waste lithium-ion battery to be treated in this embodiment is a lithium-ion battery whose cathode material is lithium manganate collected from the market. The method for reclaiming the cathode material of the waste lithium ion battery in this embodiment and then using it to prepare the cathode material of the lithium ion battery comprises the following steps:

[0028] 1) Disassemble the battery in an anhydrous glove box, open the shell of the used battery, separate the cathode sheet of the battery from the battery, soak the cathode sheet in dimethyl carbonate, and make the electrolyte impurities contained in the cathode sheet Dissolve in dimethyl carbonate, wash away the electrolyte with dimethyl carbonate (DMC), filter again, and collect the cathode sheet. After the cathode sheet is taken out, put it into the water, separate the lithium manganate cathode material from the aluminum sheet by means of ultrasonic waves, and then sieve the cathode material and the alumi...

Embodiment 3

[0032] The waste lithium ion battery to be processed in this embodiment is a lithium ion battery whose cathode material is lithium nickel manganese cobalt oxide collected from the market. The method for reclaiming the cathode material of the waste lithium-ion battery in this embodiment and then using it to prepare the cathode material of the lithium-ion battery comprises the following steps:

[0033]1) Disassemble the battery in an anhydrous glove box, open the shell of the used battery, separate the cathode sheet of the battery from the battery, soak the cathode sheet in dimethyl carbonate, and make the electrolyte impurities contained in the cathode sheet Dissolve in dimethyl carbonate, wash away the electrolyte with dimethyl carbonate, and then filter to collect the cathode sheet. The cathode material on the cathode sheet is separated from the aluminum sheet by brushing, and the separated cathode material lithium nickel manganese cobaltate is dried.

[0034] 2) Determinati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com