Flexible Insulation Structure of High Power Electromagnetic Relay

An electromagnetic relay, high-power technology, applied in electromagnetic relays, electromagnetic relay details, relays, etc., can solve the problems of contact resistance thermally affecting product electrical life performance indicators, increasing product contact resistance, and reducing product reliability. Achieve the effect of preventing action jams, improving product reliability, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

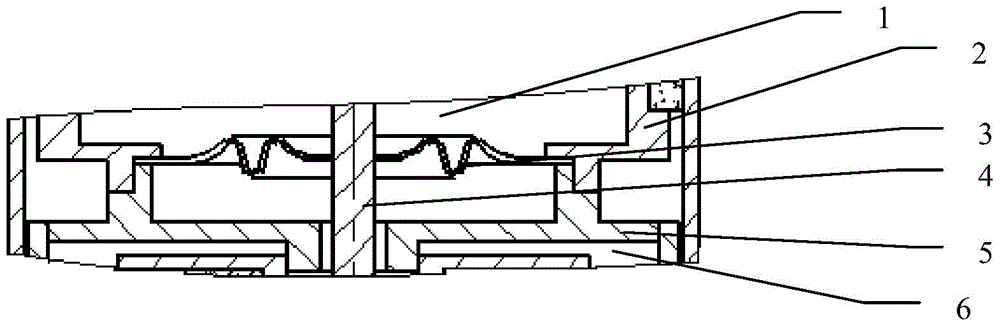

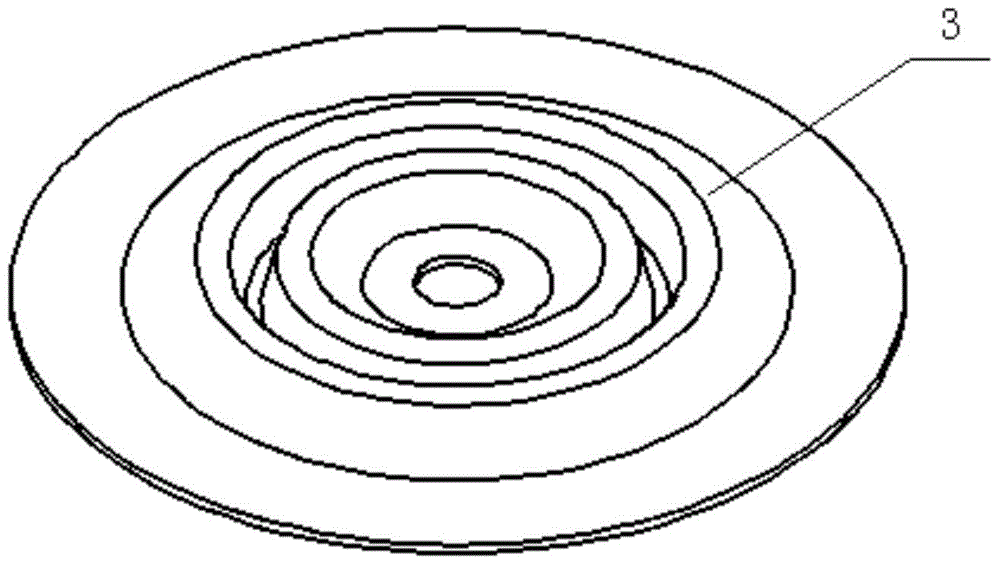

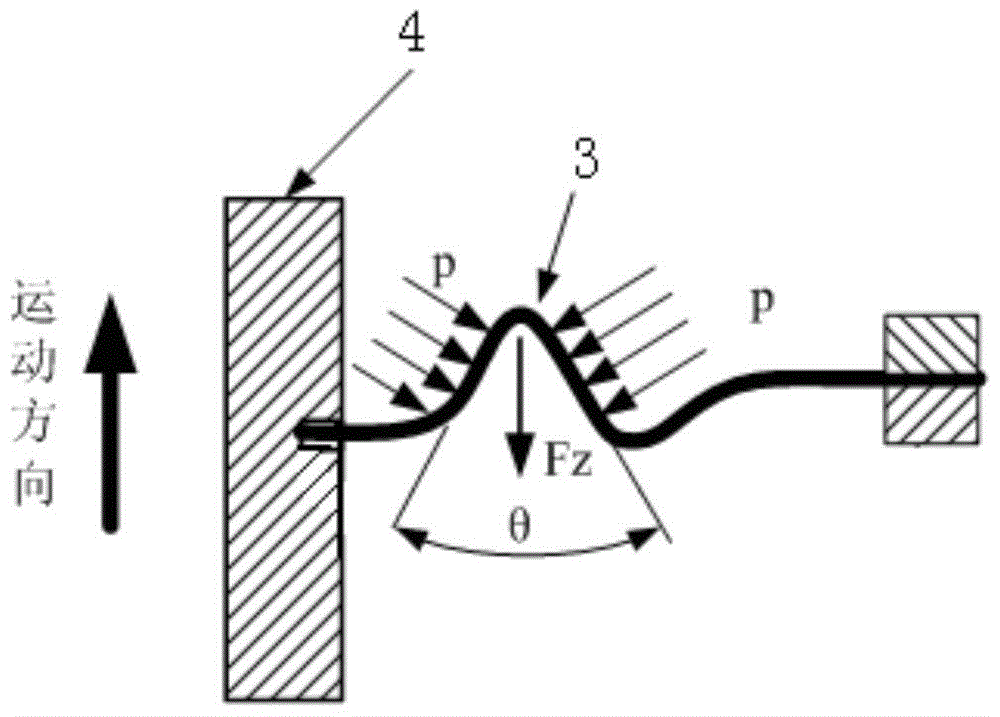

[0018] Such as figure 1 shown. The flexible barrier structure of the high-power sealed relay of the present invention includes: a contact system cavity 1, an arc extinguishing cavity cover 2, a flexible barrier 3, a transmission shaft 4, a yoke 5 and an electromagnetic system cavity 6; the flexible barrier 3 is the center A disc with a round hole and a wrinkled surface, the cross-section of the flexible barrier 3 is a wedge-shaped symmetrical left and right; the flexible barrier 3 is fitted on the transmission shaft 4 with interference fit; Between the arc extinguishing chamber cover 2 and the yoke 5; the arc extinguishing chamber cover 2 is fixedly connected to the contact system cavity 1; the yoke 5 is fixedly connected to the electromagnetic system cavity 6.

[0019] When the high-power electromagnetic relay is working, there will be arcing in the cavity 1 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com